Loading ...

Loading ...

Loading ...

I

=-,

SERVICE

&

MAINTENANCE INSTRUCTIONS

SERVICE

&

MAINTENANCE INSTRUCTIONS

Keep hands and body away from pressurized lines.

Use paper

or

cardboard, not body parts to check

for leaks.

4-

Hydraulic fluid (oil) under

pressure will penetrate skin causing serious

injury.

Make sure that all operating and service

personnel

knowthat In the event hydraulic fluid

penetrates skin, it must be surgically removed

within a few hours by a doctor familiar with this

form of injury, or gangrene may result.

Make sure that all operating and service personnel

know that in the event hydraulic fluid penetrates

skin, it must be surgically removed within a few

hours by a doctor familiar with this form of injury,

or

gangrene may result.

Always wear relatively tight and belted clothing to

avoid entanglement in moving parts. Wear sturdy,

rough

-

soled work shoes and protective equipment

for eyes, hands, hearing and head.

Before working on backhoe, extend boom and

dipperstickand place bucket on ground. Make sure

that all system pressure has been relieved by

operating controls before maintenance, service

or

disconnecting any hydraulic lines.

m

Hydraulic system leak down

and failure

of

mechanical or hydraulic system

can cause equipment to drop causing injury.

Make sure all hydraulic pressure is relieved off

of the backhoe before performing service on

the equipment.

Hydraulic System (Figure

25)

A-

Daily, check the fluid level in reservoir with filler cap

dipstick. Contamination will shorten the

life

of

hydraulicsystem components. Change oil and filter

after first

20

hours of operation and then every

200

hours of operation

or

annually, whichever occurs

first.

In

extremely dusty

or

dry conditions, more

frequent changes may be necessary. System

capacity

is

approximately

5

to

5

-

1/2

U.S.

gallons.

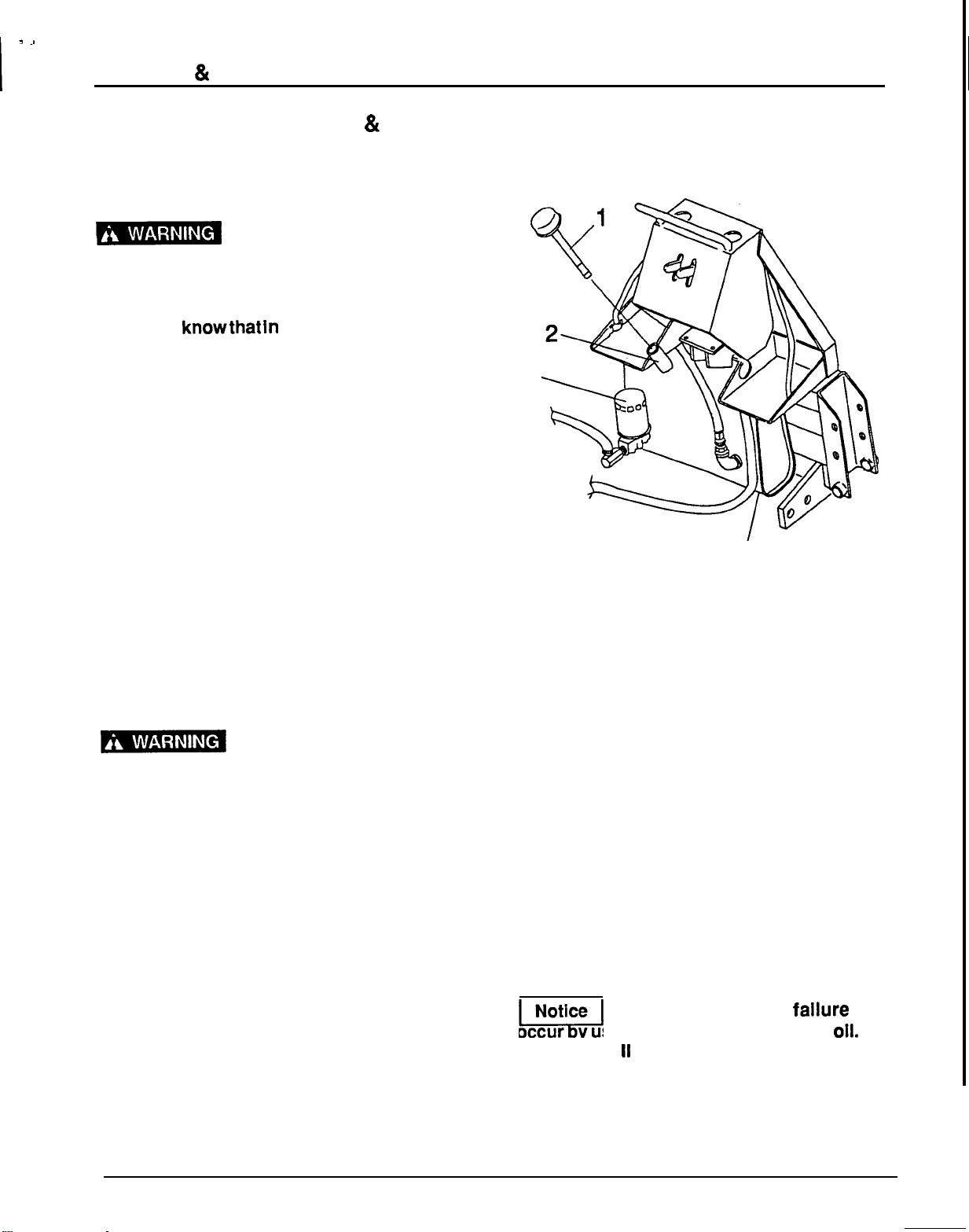

1.

Operate tractor PTO at

540

rpm until the

system reaches operating temperature.

3

4

1.

Oil

breather cap

3.

Oil

filter

2.

Oil

filler

neck

4.

Oil drain

plug

Figure

25.

Oil Maintenance

2.

Remove the drain plug

(4)

from the hydraulic

oil

reservoir.

3.

Drain the oil into a suitable container and

dispose of properly.

Note: Please dispose of used hydraulic

oil

in a

manner that is compatible with the environment.

Do not throw it in the trash

or

pour it on the ground.

4.

Put the oil pan under the oil filter

(3).

Remove

the hydraulic oil filter.

5.

Clean the oil filter mounting base. Lightly

lubricate the new filter O

-

ring and install the

filter onto the base.

6.

Fill

with clean oil.

Do

not mix oil types orgrades.

rn

Hydraulic system fallure may

occur y using an unsuitable hydraulic

oil.

Use

only Dexron

II

type

ATF.

7.

ENGAGE PTO AND RUN AT IDLE

FOR

5

MINUTES, THEN CHECK

OIL

LEVEL. Add

fluid as necessary.

35

Loading ...

Loading ...

Loading ...