Loading ...

Loading ...

Loading ...

REPLACEMENTOFCARBON BRUSHES cent.

3 Using a siotled screwdriver, remove the black

piastlc cap on each side of the motor housing

{Fig 23), and carefully withdraw the

spring-loaded brush assemblies Keep brushes

clean and sliding freely in their guide channels

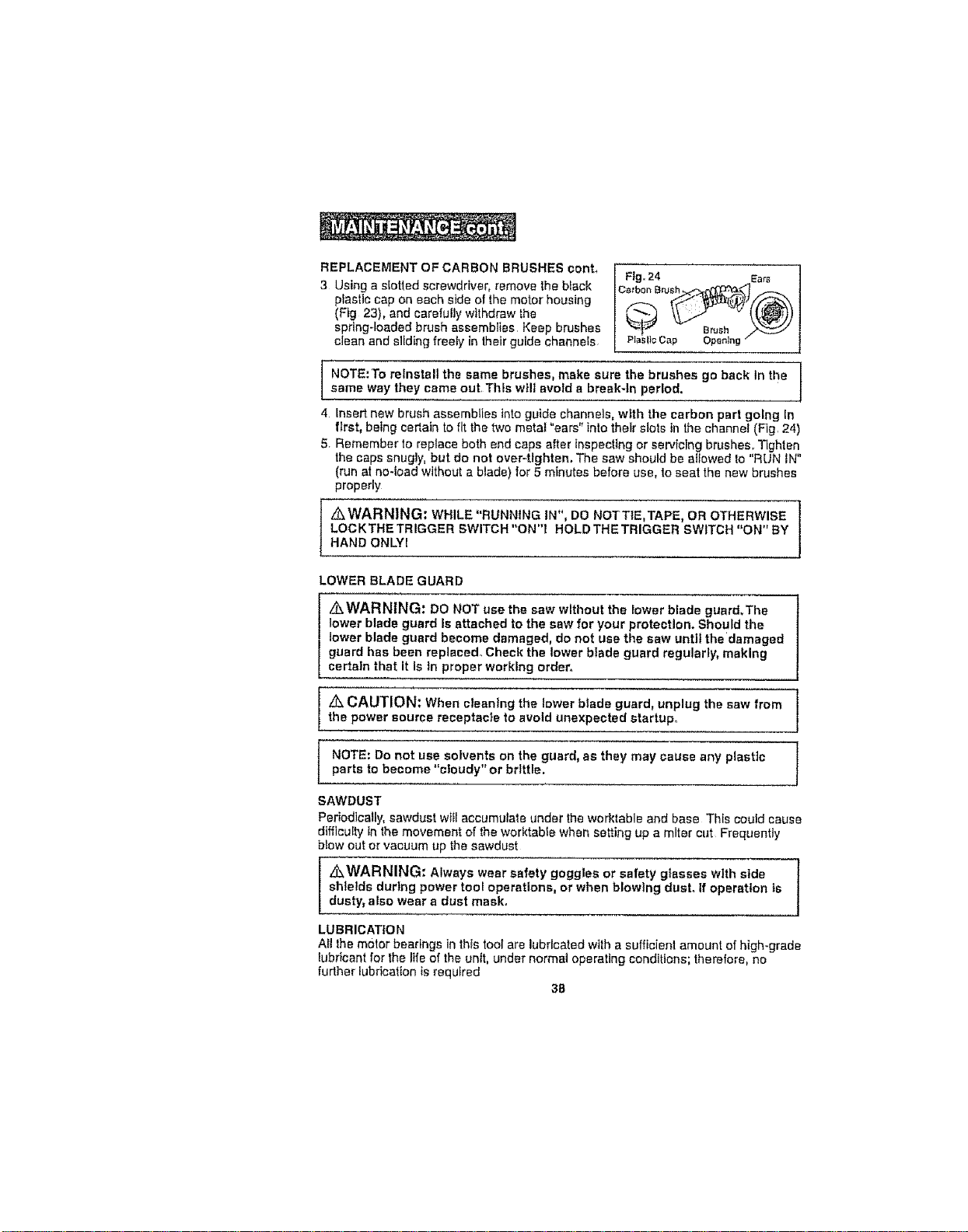

Fig. 24 Ears

Catb0n B___ __

-'*_J Brush

P_BI_;Cap Opening

NOTE:To reinstall the same brushes, make sure the brushes go back In the

same way they came out, This will avoid a break-in period.

4 insert new brush assemblies into guide channels, with the carbon part going In

first, being cedatn to fit the two metal "ears" into their slots in the channel (Fig. 24)

5. Remember to replace both end caps after Inspectlng or servicing brushes. Tighten

the caps snugly, but do not over-tlghtem The saw should be allowed to "RUN iN"

(run at no-load without a blade) for 5 minutes before usa, to seat the new brushes

properly

z_WARNING: WHILE "RUNNING IN*', DO NeTTlE,TAPE, OR OTHERWISE ]

LOCKTHETRIGGER SWITCH"ON"! HOLDTHETRIGGER SWITCH "ON"BY

J

HAND ONLYI

LOWER BLADE GUARD

_WARNING: DO NOT use the saw without the lower blade guard.The

lower blade guard is attached to the saw for your protection. Should the

lower blade guard become damaged, do not use the saw until thedamaged

guard has been replacedo Check the lower blade guard regularly, making

certain that it Is In proper working order°

z%,CAUTION: When cleaning the lower blade guard, unplug the saw from

the power source receptacle to avoid unexpected startUpo

NOTE; Do not use solvents on the guard, as they may cause any plastic

parts to become "c;oudy" or brittle.

SAWDUST

Periodically, sawdust wffl accumulate under the worktable and base This could cause

difficulty in the movement of the worktable when setting up a miter cut Frequently

blow out or vacuum up the sawdust

z&WARNING: Always wear safety goggles or safety glasses with slde

shletds during power tooi operations, or when blowing dust. If operation ts

dusty, also wear s dust mask,

LUBRICATION

AII Ihe motor bearings in th_stool are lubricated wttha sufficient amount of high-grade

lubricant for the life of the unit, under normal operating conditions; therefore, no

further lubrication is required

38

Loading ...

Loading ...

Loading ...