Loading ...

Loading ...

Loading ...

(continued)

Inspect any problems reported by owner and correct before

proceeding.

1. Verify that boiler area is free of any combustible materials,

gasoline and other ammable vapors and liquids.

2. Verify that air intake area is free of any of the contaminants

listed on page19 of this manual. If any of these are present

in the boiler intake air vicinity, they must be removed. If

they cannot be removed, reinstall the air and vent lines per

this manual.

1. Remove jacket front door and inspect interior of boiler.

2. Visually inspect the door gaskets. Make sure all are in good

condition. Obtain replacements if any gasket is damaged.

Door gaskets must be intact, and must provide a

reliable seal. Replace any damaged gasket.

3. Remove the venturi air inlet silencer and clean if necessary.

Reinstall silencer.

4. Vacuum any sediment from the inside of the boiler and

components. Remove any obstructions.

Do not use solvents to clean any of the boiler

components. e components could be damaged,

resulting in unreliable or unsafe operation.

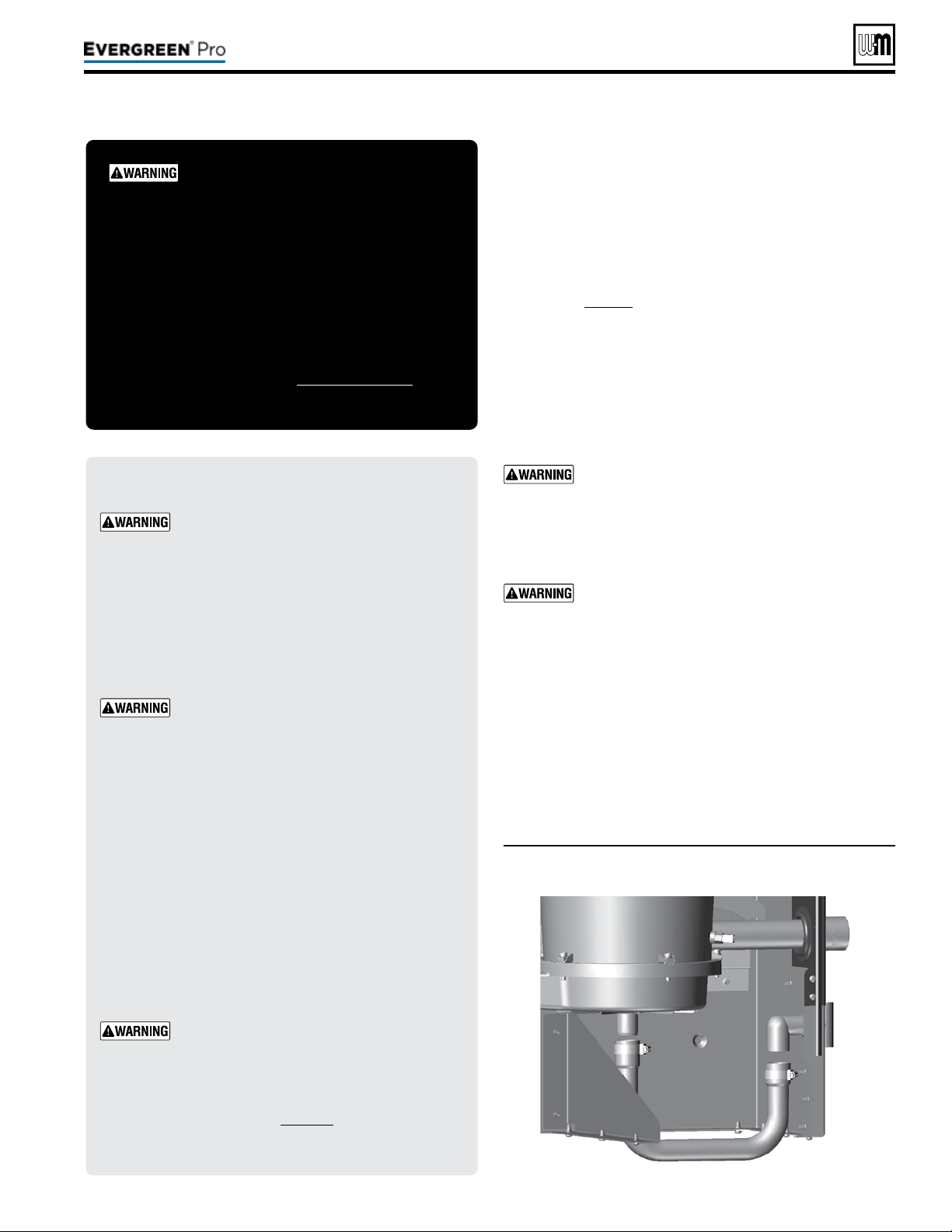

1. See Figure91. Loosen condensate trap line hose clamps and

remove trap line.

2. Empty water from trap line and inspect. Flush out if needed

with fresh water.

3. Check condensate elbow, tee, and condensate line to drain.

Flush if necessary to clean.

4. Fill trap with fresh water.

5. Reinstall condensate trap line and tighten hose clamps.

DO NOT SERV I CE T H E BOI LER

WI THOUT AN Evergre en

®

INSPECTION K I T AVAILABLE

Before each annual inspection, obtain an EVG Inspection

Kit, which includes parts required for the procedures

given in this manual. It is recommended to also obtain

an EVG Maintenance Kit, which includes additional parts

that may be required if inspection of components indicates

the need for replacement. See Replacement parts for kit

part numbers.

ELECTRICALSHOCKHAZARD — Discon-

nect all electrical power to the boiler before

attempting maintenance procedures. Failure

to complete could result in severe personal

injury, death or substantial property damage.

Reinstall boiler jacket door aer start-up or

servicing. e boiler front door must be se-

curely fastened to the boiler to prevent boiler

from drawing air from inside the boiler room.

is is particularly important if the boiler is

located in the same room as other appliances.

Inspect boiler jacket door gaskets. Gaskets

must be in good condition, with no tears or

gaps. Replace if necessary.

Failure to keep the door securely sealed and

fastened could result in severe personal injury

or death.

Removing and reinstalling components can

change boiler behavior. Aer any maintenance

procedure, you must prove the boiler is oper-

ating correctly. To do so, follow the complete

procedure for boiler and system start-up,

beginning on page86. Failure to comply

could result in severe personal injury, death

or substantial property damage.

Part number 550-100-211/0122

– 95 –

220 /29 9/3 00 /39 9

Figure91 Condensate drain line cleaning

Loading ...

Loading ...

Loading ...