Loading ...

Loading ...

Loading ...

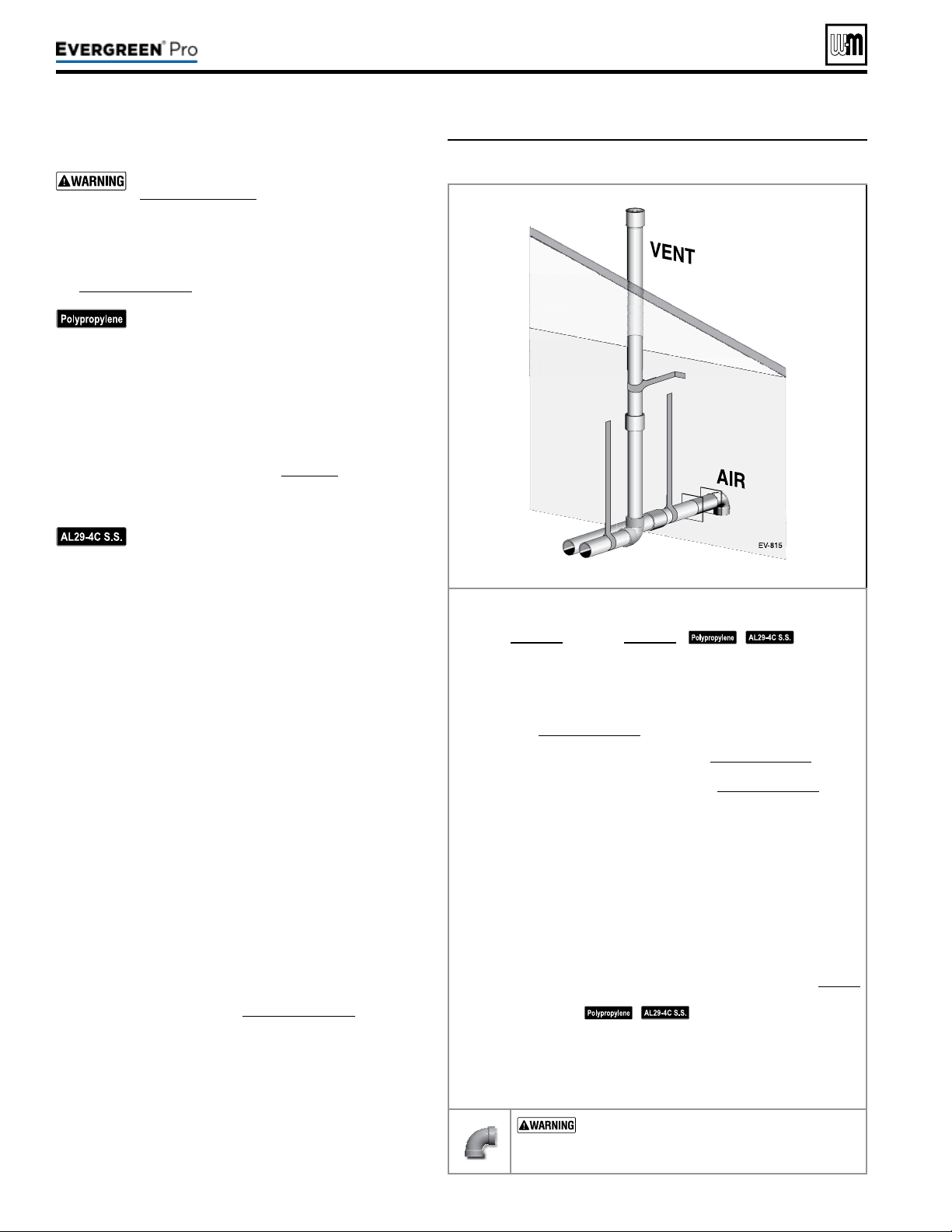

DIRECT VEN T

Figure43 INSTALLATIONSEQUENCE — Vertical vent/

sidewall air

Allowablevent/airpipematerials&lengths

Use only the vent materials and kits listed in

Figure24,page21. Provide pipe adapters if

specied.

1. Locate the terminations such that the total air pip-

ing and vent piping from the boiler to the termina-

tion will not exceed the maximum length given in

Figure23,page20.

For polypropylene applications, comply with

any additional requirements in the vent sys-

tem manufacturer’s instructions. Provide 4”

PVC-to-PP transition pieces at the boiler vent

and air connections. PP adapter must have

smooth, straight section of pipe to insert in to

the boiler vent and air connections and must

t and seal tightly. PP adapters with their own

seal which would interfere with the internal

seal of the boiler vent or air connections must

not be used. Refer to page117 for a list of

compliant adapters. Install a locking collar at

every joint.

For AL29-4C vent pipe applications, comply

with any additional requirements in the vent

system manufacturer’s instructions. Provide

a 4”PVC transition piece at the boiler vent

connection. e air piping must be PVC or

CPVC.

2. For 4” to 3” transitions, must use appropriate vent

material. For polypropylene or stainless steel must use

approved suppliers transitions (EVG 220 only).

Prepareroofpenetration

1. Vent pipe penetration:

a. Cut a hole for the vent pipe. For either combustible

or noncombustible construction, size the vent pipe

hole at least 0.4” larger than the vent pipe diameter.

b. Insert a galvanized metal thimble in the vent pipe

hole.

2. Follow all local codes for isolation of vent pipe when

passing through oors, ceilings and roofs.

3. Provide ashing and sealing boots sized for the vent

pipe and air pipe.

Ventterminationandttings

1. Prepare the vent termination coupling by inserting a bird

screen. Bird screens must be purchased separately. See

the parts list at the end of this manual for part numbers.

2. Maintain the required dimensions of the nished termi-

nation piping as shown in Figure44,page37.

Multipleventterminations

1. When terminating multiple Evergreen boilers, ter-

minate each vent/air connection as described in this

section.

2. Place adjacent terminations at least 6 inches apart.

3. For Canadian installations, provide clearances required

by Natural Gas and Propane Installation

CAN/CSA

B149.1 or B149.2 Installation Code.

Part number 550-100-211/0122

– 36 –

Step1 Read and follow all instructions in this manual. DO NOT

proceedwithvent/airinstallationuntilyouhaveread

page19throughpage24.

See notices

at le.

Step2 Install the boiler in a location that allows proper routing of all

vent and air piping to the selected locations.

Step3 Make sure the selected vertical termination location complies

with Figure25,page23.

Step4 Use only the vent materials listed in Figure24,page21. Provide

pipe adapters where required. Vent piping and air piping lengths

must not exceed the values shown in Figure23,page20.

Step5 Prepare the vertical penetration (vent) and sidewall penetra-

tion (air) and secure penetration components as instructed in

this section.

Step6 e air piping must terminate in a 90-degree down-turned

elbow as shown above. e vent piping must terminate in a

couplingpointedupward as shown above.

Step7 Install vent and air piping between the boiler and the air and

vent terminations. Slope horizontal piping downward toward

the boiler at least 1/4 inch per foot. Install pipe supports every

5 feet on both the horizontal and vertical runs. Install a hanger

support within 6inches of any upturn in the piping. See page38

for general guidelines. Also comply with vent pipe manufacturer’s

instructions.

See notices at le.

Step8 Insert the vent and air piping through the penetrations and secure

the termination ttings.

Step9 Maintain clearances shown in this section. Vent and air termina-

tions must be tted with bird screens as shown.

USESWEEPELBOWSFORALLVENTAND

AIR PIPING — DO NOT use short radius elbows

for vent or air piping. Boiler performance could be

aected.

220 /29 9/3 00 /39 9

Loading ...

Loading ...

Loading ...