Loading ...

Loading ...

Loading ...

Figure15 Gas valve adjustment locations—ONLY for use

by a qualied technician, using properly working,

calibrated combustion test instruments.

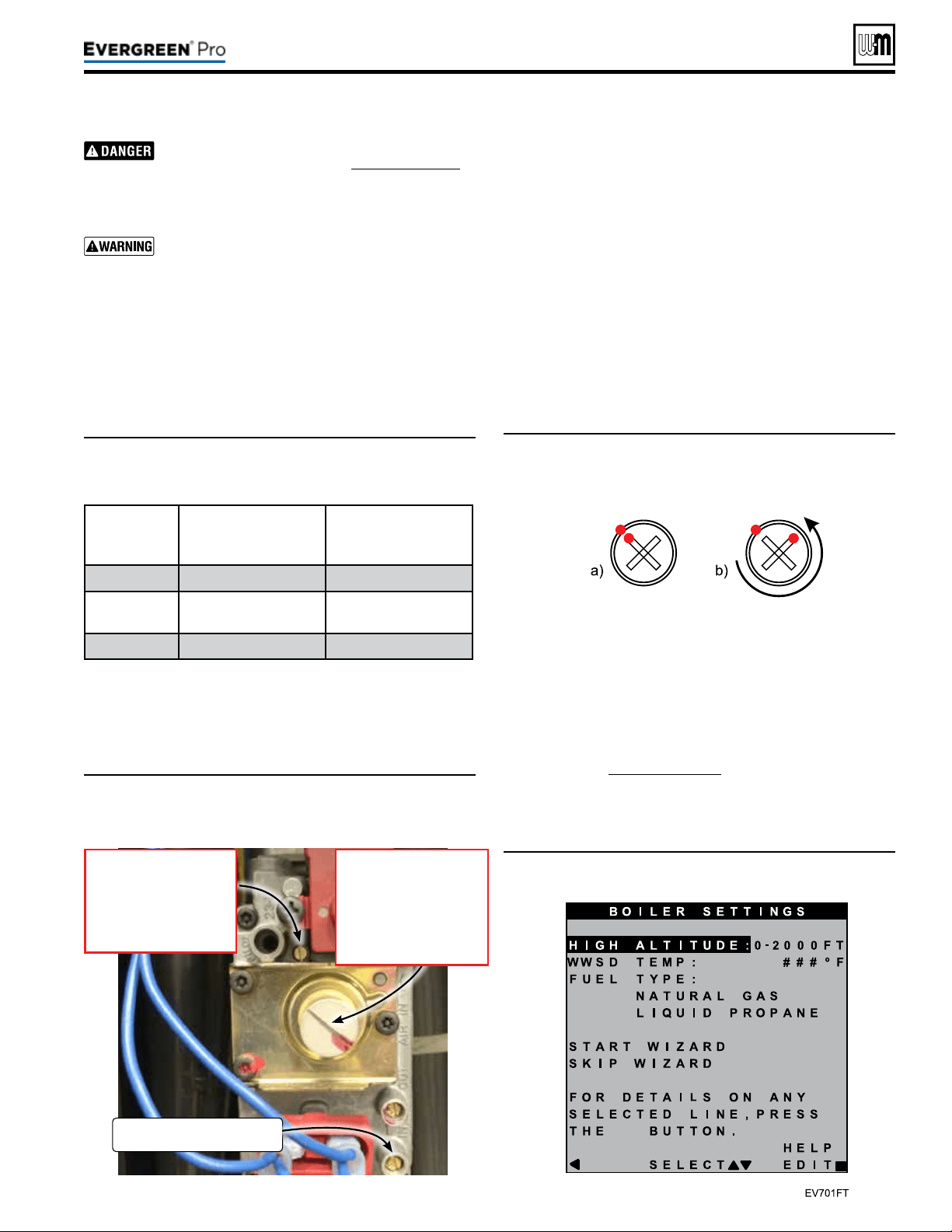

Figure16 Offset regulating screw adjustment—(a)

Marking factory-provided NG position. (b) View

after 3/4 turn CCW adjustment.

Figure17 Evergreen

®

fuel type setting screen

Part number 550-100-211/0122

– 15 –

220 /29 9/3 00 /39 9

Inspect the gas pipe tting connections on the gas

valve and new venturi (Item3, Figure14,page14).

Check the seal of the connections. Failure to

comply will cause a gas leak, resulting in severe

personal injury or death.

Do not check for gas leaks with an open ame —

use bubble test. Failure to use bubble test or check

for gas leaks can cause severe personal injury,

death or substantial property damage.

13. Prior to the boiler’s rst ignition, adjust the throttle adjust-

ment screw by rst turning the screw clockwise (P) until it

bottoms out – do not apply any additional or excess torque.

Adjust the throttle screw in a counterclockwise (Q) direc-

tion with precisely the number of turns listed in Table 1,

according to the boiler model/size.

(continued)

Table1: Course adjustment settings—Throttle and offset

adjustments to be made prior to rst ignition, by

size.

Boiler

Model

ThrottleTurns

(Counterclockwise Q from

Bottom-out Position)

OffsetTurns

(Counterclockwise Q

Factory NG Position )

EVG 220LP

5/8 3/4

EVG

299/300LP

1-3/8 1/4

EVG 399LP

1-5/8 1/4

14. Aer the throttle has been adjusted coarsely, the oset regulat-

ing screw must be adjusted. Remove the sealed, slotted cap

protecting the white oset regulating screw before making

adjustments. It is critical to be precise for the adjustment of

the oset regulating screw. DO NOT attempt to bottom out

the oset regulating screw as was done for the throttle adjust-

ment. Adjustments to the oset regulating screw should be

made from the factory-provided natural gas position.

Adjust the oset regulating screw using the follow-

ing steps, referencing Figure16

:

1a. Use a marker to mark the corner of one tip of the cross on

the oset regulating screw and the corresponding location

on the outside of the screw housing, as shown in Figure16a.

2b. Adjust the oset regulating screw in a counterclockwise (Q)

direction with precisely the number of turns listed in Table

1, according to the boiler model/size.

15. Reconnect wire harness to gas valve.

16. Restore electrical power, turn on gas by opening manual gas

valve and check for leaks.

17. When boiler has not been red, follow instructions on the

initial screens to select propane as the gas type. If natural

gas was already selected in the boiler control, the gas type

parameter will need to be adjusted. In the contractor menu,

under the Boiler Settings menu, adjust the “LP Gas” setting

to “YES”, see Figure75,page76.

18. Before ring, verify that the Boiler Settings are for LP gas,

“Max Rate” for the input (priority) used to re the boiler

GasInletPressure

TestPort

OffsetRegulatingscrew

• Turn clockwise

to increase CO

2

. P

• Turn counter-clockwise to

decrease CO

2

. Q

Note: Must remove cover.

Throttle adjustmentscrew

• Turn counter-clockwise

to increase CO

2

. Q

• Turn clockwise to

decrease CO

2

. P

Loading ...

Loading ...

Loading ...