Loading ...

Loading ...

Loading ...

Part number 550-100-211/0122

– 42 –

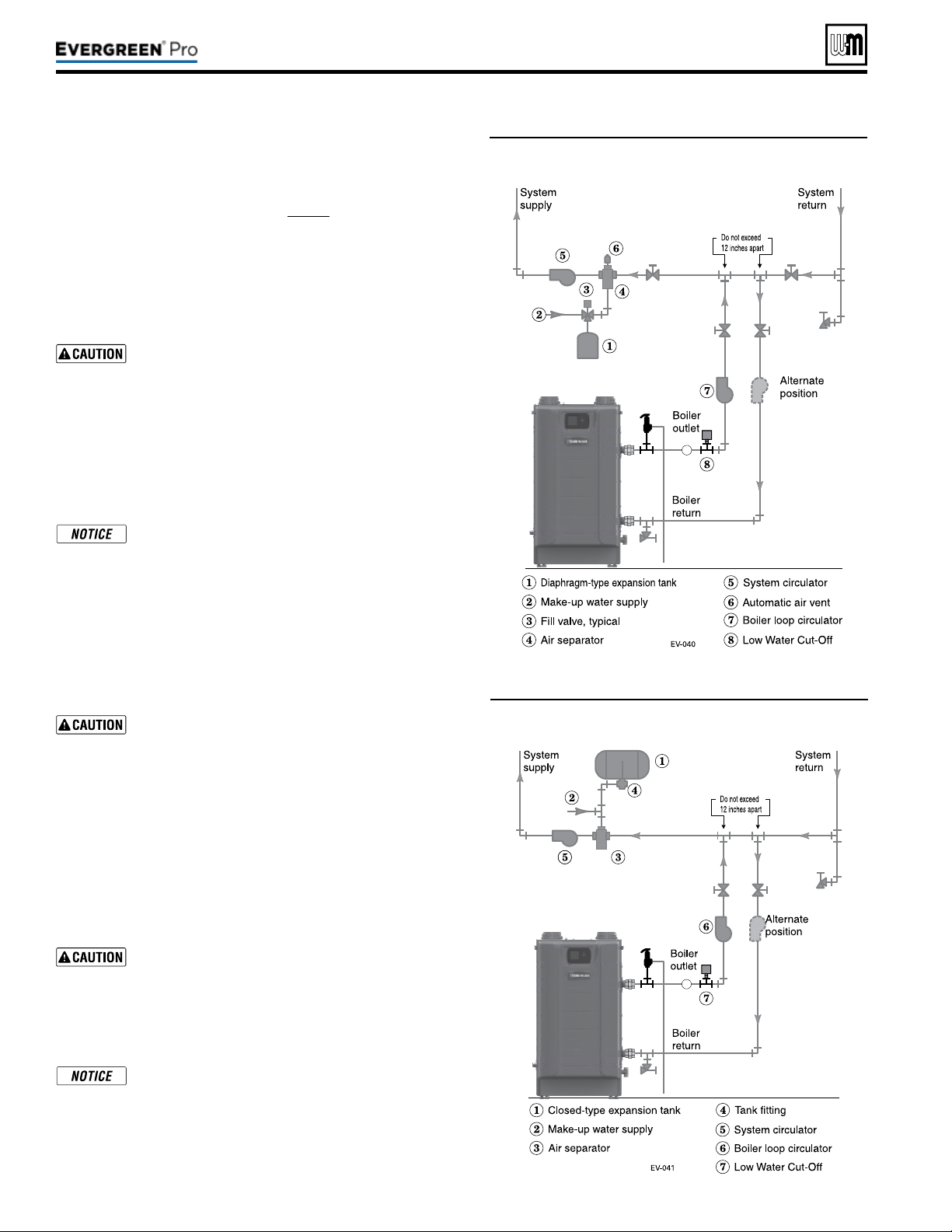

Figure50 and Figure51 show typical installations of the system expansion

tank. Always locate the air separator and expansion tank as shown in the

suggested piping drawings, beginning on page43.

Ensure that the expansion tank size will handle boiler and system water

volume and temperature. Allow 4.6 gallons for

Evergreen

®

220, 7.0 gal-

lons for

Evergreen

®

299/300 and 6.7 gallons for Evergreen

®

399. See

tank manufacturer’s instructions and ratings for details. Additional tanks

may be added to the system if needed to handle the expansion. ese tanks

may be installed by connecting to tees in the system piping.

Undersized expansion tanks cause system water to

be lost from the relief valve and makeup water to be added

through the ll valve. Eventual boiler failure can result due

to excessive make-up water addition. Always locate the cold

waterllconnection at the expansion tank. Never locate

this elsewhere in the system.

Diaphragm-orbladder-typetank:

Refer to Figure50 for suggested piping when using a diaphragm- or

bladder-type expansion tank.

Diaphragm-orbladder-typeexpansiontank — Con-

trol llpressure with the tank air charge pressure. Always

check pressure and charge tank with tank removed from

system to be sure reading is accurate. Boiler relief valve is set

for 30 PSIG. Operating pressure of system, aer temperature

expansion above cold ll pressure, should not exceed 24 PSIG

to avoid weeping of relief valve.

Install an automaticairvent on top of the air separator, per separator

manufacturer’s instructions.

Closed-typeexpansiontank:

DO NOT use a closed-type tank if connecting to a water

heater that is equipped with an automatic air vent.

Figure51 shows suggested piping when using a closed-type expansion tank,

in which the air is directly in contact with tank water.

Connect piping (½” or ¾”) from the air separator top outlet to the tank

tting. Slope any horizontal piping a minimum of 1inch per 5feet of

horizontal pipe.

Always use a tanktting, such as the B&G Ta n kt ro l or Taco Taco-Trol

(shown). e tting reduces gravity ow of water in the piping to the tank,

avoids air bubbling through the tank water, and provides the proper ll

height in the tank.

Correctallleaks in the system or tank piping. Leaks allow

air to escape from the system and will cause water-logging

of the tank. is will result in water loss through the boiler

relief valve due to over-pressurization. NEVER use an

automatic air vent in a system equipped with a closed-type

expansion tank. e air removed from the system will cause

water-logging of the expansion tank.

Closed-type expansion tank — Follow tank manu-

facturer’s instructions for llingthetank. Typical tank

sizing provides for approximately 12 PSIG when the tank

is lled to the normal level and system water is cold. Note

that boiler relief valve is set for 30 PSIG. Operating pres-

sure of system, aer temperature expansion above cold ll

pressure, should not exceed 24 PSIG to avoid weeping of

relief valve.

Figure50 Piping to diaphragm (or bladder) type

expansion tank

Figure51 Piping to closed -type expansion tank

220 /29 9/3 00 /39 9

Loading ...

Loading ...

Loading ...