Loading ...

Loading ...

Loading ...

(see wiring diagram, Figure 65, page 59)

Part number 550-100-211/0122

– 52 –

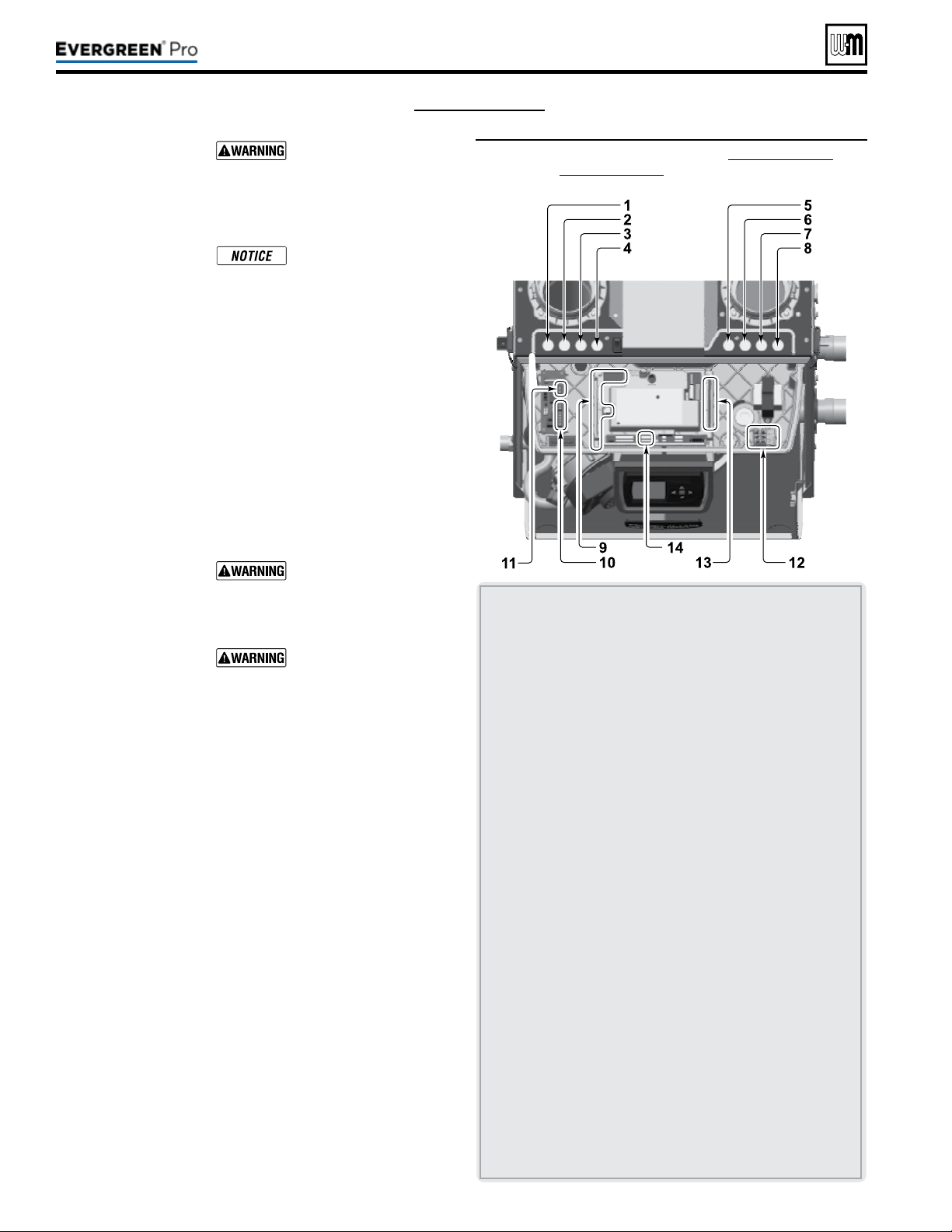

Figure64 Field wiring overview (see Figure 65, page 59 and

Figure 66, page 60 for detailed schematic and ladder

wiring diagrams)

ELECTRICALSHOCK HAZARD — For your safety, turn o

electrical power supply at service entrance panel before making

any electrical connections to avoid possible electric shock hazard.

Failure to do so can cause severe personal injury or death.

e installation must comply with National Electrical Code and

any other national, state, provincial or local codes or regulations.

In Canada, CSA C22.1 Canadian Electrical Code Part 1, and any

local codes.

Wiring must be N.E.C. Class 1. If original wiring as supplied with

boiler must be replaced, use only type 105 °C wire or equivalent.

Boiler must be electrically grounded as required by National

Electrical Code ANSI/NFPA 70 – latest edition.

Do not use 24V from transformer to power any external devices

that are not listed in this manual.

Eight knockouts are provided in the top of the cabinet for line

and low voltage wiring. See Figure64 for locations and functions.

InstallerMUSTuseastrainrelief through jacket knockouts.

Failure to do so can cause severe personal injury, death or sub-

stantial property damage.

InstallerMUSTSEAL all electrical entrances using a sealed strain

relief or a strain relief sealed with duct seal putty or silicone.

Sealing the entrances prevents water from entering the electrical

enclosure. Failure to seal entrances could result in severe personal

injury, death or substantial property damage.

See details on the following pages for the wiring connections

outlined below:

Requiredwiringconnections

y 120VAC power to boiler; 120VAC power out to boiler cir-

culator; system supply and return temperature sensors; and

outdoor temperature sensor (unless exempt as described in

this manual).

Connectionsasneededbysystems

y ermostat, end switch or other inputs for call for heat.

y System zone circulators, valves, relays, etc.

y System circulator, when required.

y Low water cut-o (when required).

Optionalwiringconnections

y External limits; proof-of-closure interlocks (combustion air

damper, ow switch, etc.); 0–10VDC for target or modulation

control; remote alarm; additional heat demand contact; and

communication cables for boiler networking and/or building

management system interface (MODBUS).

1 120VAC knockout for power to boiler circulator terminals at

item11.

2 For wiring to P12 – Low water cuto kit (when used) wire

harness should be routed through this knockout with no

other wires. Provide strain relief and a seal at cabinet entry.

3&4 Two knockouts for low voltage wires to terminal strips at

items9 and 10 (terminal strips P10, P11, P13, P14, P15 and

P16). ese knockouts are provided with multi-hole cord

grips. Use if allowed by codes.

• ermostat, aquastat, limit device, outdoor temperature

sensor, system temperature sensor, and boiler communica-

tion wiring should be mounted through the cord grip.

• Mount cord grip to desired low voltage knockout and

secure with a locknut before passing wire through cord grip.

• Aer all wires are routed through cord grip holes and

secured to connecting terminals, hand tighten the nut on top

of the cord grip to seal any unused holes and grip the wires

tightly.

5,6,7&8 Four knockouts for 120VAC wiring to power in (at

item12) and three 120VAC outputs on terminal strip (at

item13).

9 Low voltage connection terminal strips are shipped loose

with boiler and must be plugged into receptacles on control

module.

10 Low voltage terminal strips (P4 & P5) for connection of com-

munication cables (multiple boiler applications).

11 120VAC terminal strip (P8) on Pump/Comm Board for

boiler circulator power.

12 120VAC terminal strip (T1) for boiler power supply (15-amp

breaker unless larger capacity is required for outputs con-

nected on terminal strip P2, located at item 13).

13 120VAC terminal strip (P2) for outputs to circulators or

auxiliary devices.

14 Low voltage terminal strip P7: clip jumper to wire proof-of-

closure interlocks (combustion air damper, ow switch, etc.).

220 /29 9/3 00 /39 9

Loading ...

Loading ...

Loading ...