Loading ...

Loading ...

Loading ...

Part number 550-100-211/0122

– 107 –

220 /29 9/3 00 /39 9

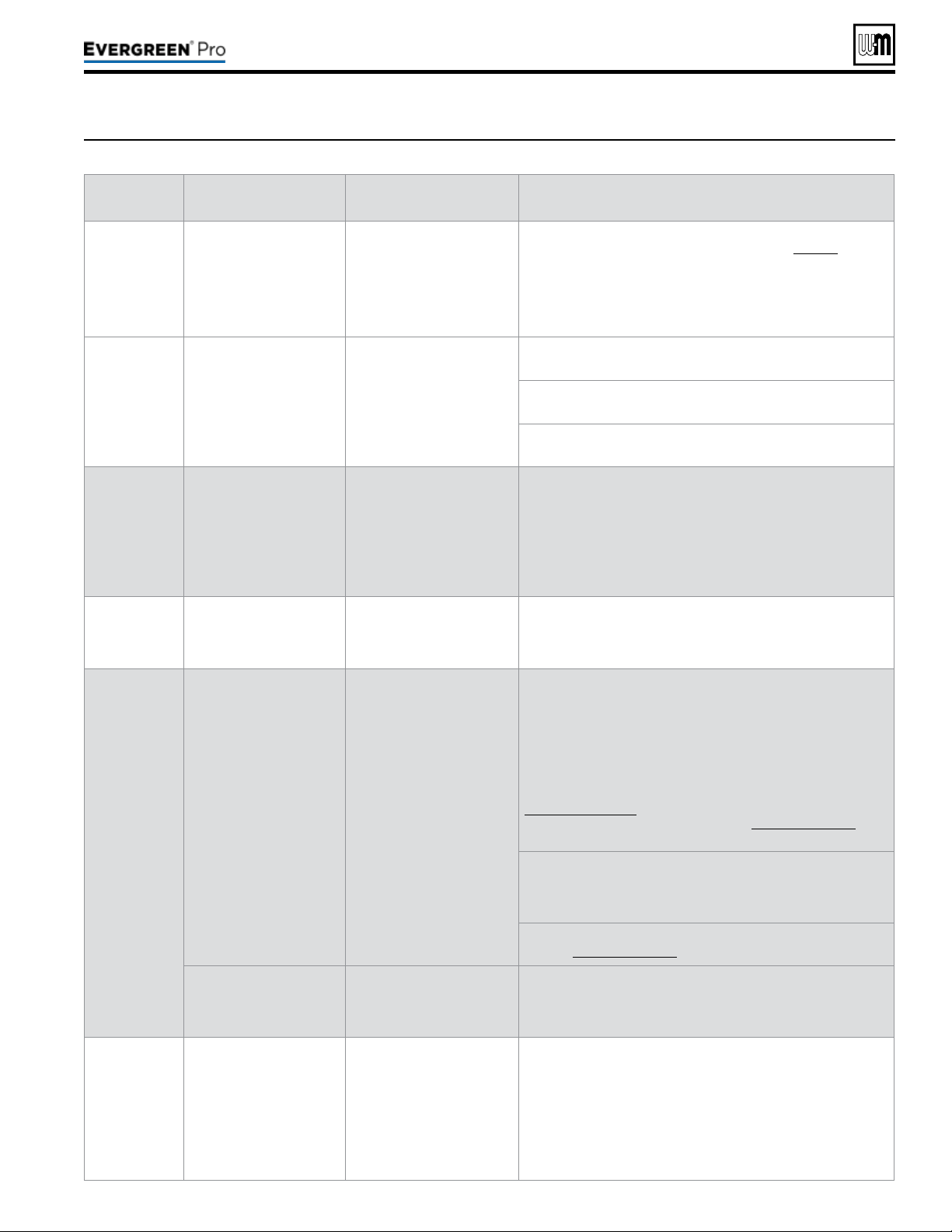

Figure103 Troubleshooting suggestions for Evergreen

®

boilers — Faultdisplays,diagnosticsandcorrectiveactions

(continued)

Display

Condition Diagnostics Corrective Action(s)

LOW WTR

CUTOFF OPEN

Occurs if internal low water

cutoff contacts open.

Automatic reset occurs if

contacts are open at least

one second, but less than

5 seconds.

Manual reset of control if

contacts are open longer

than 5 seconds.

Check for low water condition in system. Repair system as

necessary; refer to the piping section starting on page 39.

If low water condition does not exist, check Diagnostics — Inputs

screen to view status of Low Water Cutoff. If shown as OPEN

check wiring between LWCO and control. If wiring is ne, remove

LWCO and Clean probe. If problem still exist, then replace the

LWCO.

SUPPLY 58° F >

RETURN

Boiler Out temperature

has exceeded the Boiler In

temperature by more than

58º F.

Automatically resets after

30 second delay when

conditions no longer exist

or using manual reset on

display.

Verify water pipe is installed correctly per instructions in this

manual.

Verify proper circulator and speed for boiler size and system

requirements.

See message displayed TEMPERATURE SENSOR and follow

procedure for loose connections.

RETURN >

SUPPLY

Occurs if a return water

temperature is greater

than the corresponding

supply temperature by 10º

F or more.

Automatically resets when

condition no longer exists.

Verify proper ow direction of the boiler circulator.

Verify proper placement of system sensors for single or multiple

boiler system. System sensors should be on system piping not on

the boiler loop.

Verify sensors are wired to correct terminal locations.

System sensors may need to be located further away from the

boiler loop connection to the system, if proximity to the boiler loop

is causing sensors to be heated inaccurately.

SUPPLY WATER

TEMPERATURE

TOO HIGH

Occurs when the System

Supply temperature goes

above 200º F when the

burner is running.

Automatically resets when

Supply temperature goes

below 200º F.

Verify proper ow direction of the boiler circulator. This circulator

must be installed to push water through the system.

TEMPERATURE

SENSOR FAULT

Occurs if a temperature

sensor has electrically

shorted (SHORT) or has

become disconnected

(OPEN).

Will automatically reset if the

condition clears.

Check all the temperature readings of the boiler on the

DIAGNOSTICS - TEMPERATURES menu to determine if any

sensors are currently displayed as SHORT or OPEN. Compare

this to the boiler temperatures recorded in the DIAGNOSTICS -

ERRORS - LOCKOUT HISTORY # - TEMPERATURES during

the last several lockout conditions.

Determine which sensors are suspect and measure their

resistance value and compare it to the values shown in

Figure 99, page 103. If the resistance values are incorrect

replace the temperature sensor. Refer to Replacement parts for

proper part number.

Check wire harness for loose connections and pin engagement

at sensor connection, chassis mount connection through control

housing, and the control. Unplug connection at sensor and at

control and check continuity between ends.

If problem persists after checking items above, replace control.

Refer to Replacement parts for kit number.

Occurs if dual temperature

sensors values have

spread by more that 10º F

if the burner is on.

Automatically resets when

sensors are within 10º F.

Follow procedure for above for SHORT and OPEN sensor

conditions to properly diagnose sensor. If measured resistance

values of sensors convert to temperatures separated by more

than 10º F replace the sensor.

FLUE TEMP

TOO HIGH

Occurs if ue temperature

sensor exceeds 210º F

(Warning) or 220º F

(Lockout).

Automatic reset occurs if

temperature drops below

210º F for 2½ minutes.

Manual reset is required if

the temperature rises above

220° F. Reset using manual

reset screen on display.

Follow procedure for above for SHORT and OPEN sensor

conditions to properly diagnose sensor. In addition inspect heat

exchanger combustion chamber and ueways for abnormal wear

or buildup.

Inspect vent system for abnormal wear or damage.

Contact Weil-McLain Technical Support.

Loading ...

Loading ...

Loading ...