Loading ...

Loading ...

Loading ...

Part number 550-100-211/0122

– 39 –

220 /29 9/3 00 /39 9

Use two wrenches when tightening water piping

at boiler, using one of the wrenches to prevent

the boiler interior piping from turning. Failure to

support the boiler piping connections to prevent

them from turning could cause damage to boiler

components.

Additionalcontrols,ifrequired

e control uses temperature sensors to pro-

vide both high limit protection and modulating

temperature control. e control module also

provides low water protection by sensing the

temperature of the heat exchanger. Thecontrol’s

high limit function requires manual reset

.

Some codes/jurisdictions may require additional

external controls for high limit and/or low water

cuto protection.

Additionallimitcontrols

Following standard industry practices, if installation is to com-

ply with ASME or Canadian requirements, an additional high

temperature limit may be needed. Consult local requirements

for other codes/standards to determine if needed.

1. Install a manual reset high temperature limit constructed to

prevent a temperature setting above 200°F in system supply

piping between boiler and isolation valve. (Note that the

Control operating limit function shuts the boiler down at

195°F, or lower if set to a lower value.)

Multi-temperature systems — If the heat-

ing system includes circuits that require lower

temperature water (radiant slab circuits, for

example) as well as higher temperature circuits,

it is recommended to protect low-temperature

circuits with limit controls that are wired to a

Control external limit circuit terminals.

2. See instructions beginning on page52 for wiring informa-

tion.

3. When using a manual reset limit control or wiring in

the manual reset circuit, preferably set Max. Boiler Tem-

perature or Supply Max. at least 20°F less than the external

manual reset limit (i.e., set control no higher than 180°F

for a 200°F external limit, for example).

Separatelowwatercutoff

1. A separate low water cuto device is recommended when

the boiler is installed above piping level, and may be

required by certain state or local codes or insurance com-

panies. Consult local requirements to determine. See the

NOTICE above regarding the inherent protection provided

by the Control module. Low water cuto is standard equip-

ment with the Evergreen

®

boilers.

2. The Control’s integral protection is accepted in many

jurisdictions as meeting the requirement for low water

protection. See page56 for details.

3. When required, use a low water cuto designed for water

installations. Electrode probe-type is recommended.

See Replacement parts for the Weil-McLain low water cut-o

kit.

4. Purchase low water cuto and install in a tee in the supply pip-

ing above boiler.

5. See eld wiring instructions beginning on page52 for wiring

additional limit controls.

Backowpreventer

Use backow preventer in the cold water supply piping if required

by local codes.

(Baseboard,convectorsorcastironradiatorsONLY)

For residential space heating applications (other than radiant heat-

ing or unit heaters) ONLY, you can use the sizing suggestions in

Figure47.

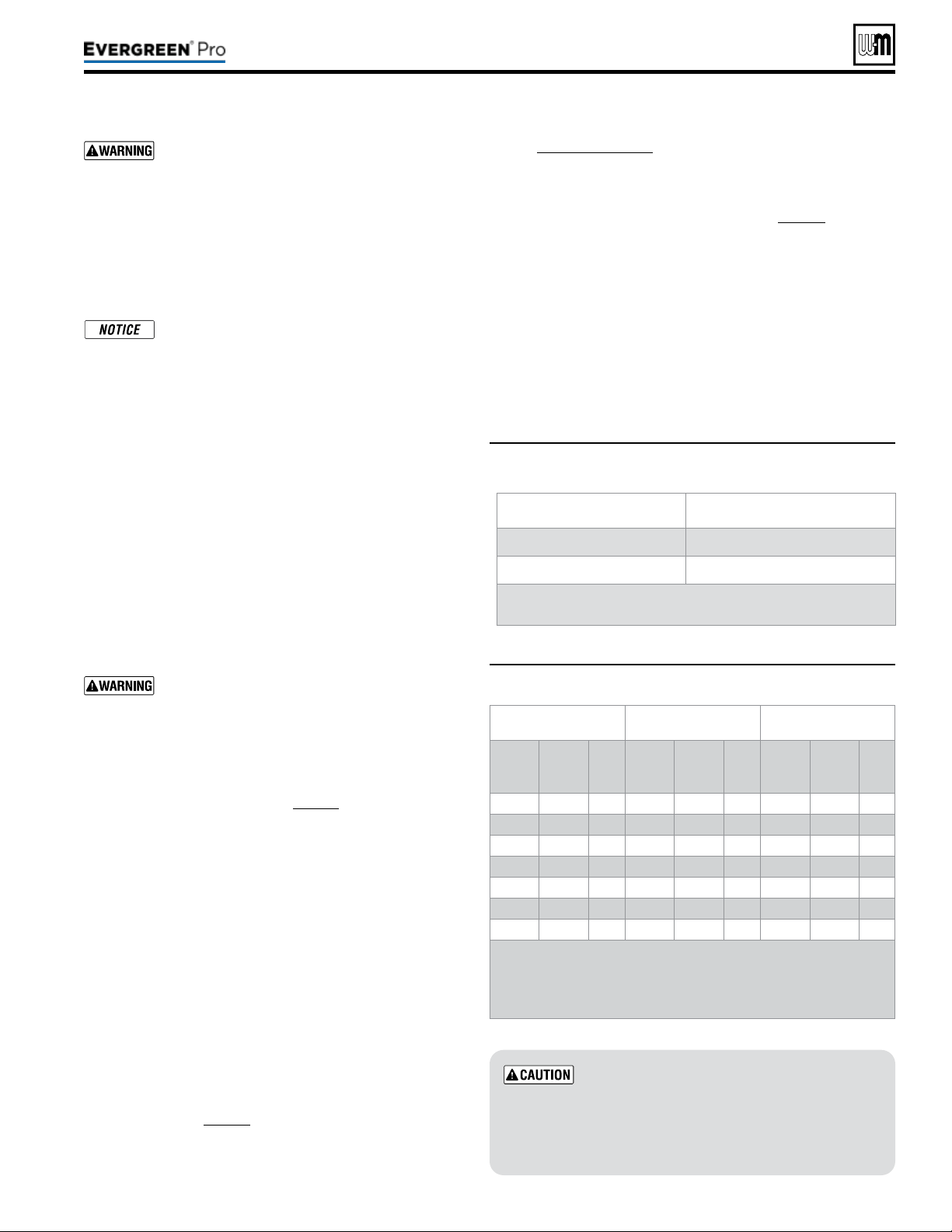

Figure47 Suggested pipe sizing for boiler loop

Use at least the MINIMUM pipe size shown in

Figure47 on all boiler loop piping (connecting

boiler to and from the primary/secondary

connection). Use only primary/secondary

piping as shown.

Failure to follow these

guidelines could result in system problems.

Figure48 Pressure drop through the Evergreen

®

heat

exchanger

EVG 220 EVG299/300 EVG 399

Flow

Rate

(GPM)

Head

Loss

(ft. w.c.)

∆T

(°F)

Flow

Rate

(GPM)

Head

Loss

(ft. w.c.)

∆T

(°F)

Flow

Rate

(GPM)

Head

Loss

(ft. w.c.)

∆T

(°F)

10** 0.0 45 13** 0.0 45 18** 0.0 45

12 0.0 37 18 0.3 33 24 0.3 33

14 0.1 31 22* 0.6 27 28* 0.7 29

16 0.2 28 28 1.2 21 32 1.1 25

18* 0.2 24 32 1.7 19 36 1.6 22

20 0.3 22 – – – 40 2.2 20

22 0.5 20 – – – – – –

* Suggested design ow rates based on a 25°F (EVG

220/299/300) and 30°F (EVG 399) temp rise through the

boiler.

** Minimum ow rates.

Model Boiler loop

EVG 220 1¼” or larger

EVG 299, 300 or 399 1½” or larger

Recommendations are based on a 25°F (EVG 220/299/300)

and 30°F (EVG 399) temp rise through the boiler.

Loading ...

Loading ...

Loading ...