Loading ...

Loading ...

Loading ...

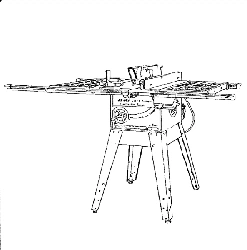

USING THE RiP FENCE

RIPPING, BEVEL RIPPING, PLOUGHING, MOLDING,

RESAWING AND RABBETING are performed usingthe

RIP FENCE together with the AUXILIARY FENCE/

WORK SUPPORT, PUSH STICK OR PUSH BLOCK.

/ WARNING: For your own safety, always observe I

i the fOllowing safety precautlo_ in addiUon to the

1

I safety instructions on pages 2, 3, 4, 5, 27, 28, & 29.

additional safety instructions for

RiP TYPE CUTS

1. NEVER use the Miler Gauge when ripping.

2. Use a Push Stick whenever the fence is 2 or more

inches from the blade. When thru-sawing, use an

auxiliary fence and push block whenever the fence

must be between 1/2 and 2 inches of the blade.

3. When using a Push Stick or Push Block, the trailing

end of the board must be square. A Push Stick or

Block against an uneven end could slip off or push

the work away from the fence.

4. A FEATHERBOARD can help guide the workpiece.

KERFS ABOUT

5/16" APART

4-1/2"

4 l

Before starting

-To avoid kickbacks and slips into the btade,

make sure the ripfence isparallel to the sawblade_

- Check the antikickback pawls. The pawls must

stop a kickback once it has started. Replace or

sharpen antikickback pawls when points become

dutt.

-Plastic and composition (like hardboard_

materials may be cut on your saw. However,

since these are usually'quite hard and slippery.

the antikickback pawls may not stop a kickback.

Therefore, be especially careful in your set-up

and cutting procedures,

While cutting

-To avoid kickbacks and slips into the blade

always push forward on the section of the work-

piece between the saw blade and the rip fence.

Never push forward on the piece being cut off,

RIPPING

Ripping

A cutting operation along the length of the workpiece,

Position the fence to the desired WIDTH OF RIP and

_ock in place.

Before starting to rip, be sure

A. Rip Fence _s parallel to sawblade.

B. Spreader is properly aligned with sawblade

C. Antikickback pawls are functioning properly

When ripping LONG BOARDS or LARGE PANELS

always use a work support.

A simple one can be made by clamping a piece of

plywood to a sawhorse.

BEVEL R|PPING NARROW WORK

When bevel r_pping material 6 in or narrower, use

fence on the right side of the blade ONLY, This will

provide more space between the fence and the

sawbiade for use of a push stick, If the fence is

mounted to the left. the sawblade guard may interfere

with proper use of a push stick.

ALWAYS SUPP©RT LONG WORKP_ECES

/1

/

J.!

46

Loading ...

Loading ...

Loading ...