Loading ...

Loading ...

Loading ...

Emergencies

If the wheel bolt is very tight, carefully push

on the end of the wheel wr

ench with your

foot. Hold on to the vehicle for support and

take care not to slip during this operation.

Loosening wheel nuts

●

Fit the wheel wrench on as far as it will go

›››

Fig. 35.

●

Hold the wrench at the end and rotate the

bolt approximately one turn anticlock-

wise

›››

.

Impor

tant information about wheel nuts

Factory-fitted rims and wheel nuts are spe-

cially matched during construction. There-

fore, if different rims are fitted, the correct

wheel nuts with the right length and heads

must be used. This ensures that wheels are

fitted securely and that the brake system

functions correctly.

In certain circumstances, you should not even

use wheel nuts from vehicles of the same

model.

In wheels with full hubcaps, the anti-theft

locking bolt must be threaded onto positions

›››

Fig. 36

2

or

3

, taking the tyre valve’s po-

sition as r

eference

1

. Otherwise it will not be

possibl

e to mount the hubcap.

WARNING

If the wheel nuts are not properly tight-

ened, they coul

d come loose while driving

and cause an accident, serious injury and

l

oss of vehicle control.

●

Use only wheel nuts which correspond to

the rim in question.

●

Never use different wheel nuts.

●

Wheel nuts and threads should be clean,

free of oil and grease, and it should be pos-

sible to screw them easily.

●

To loosen and tighten wheel nuts, only

use the wheel wrench that came with the

car from the factory.

●

The wheel nuts should only be loosened

slightly (about one turn) before raising the

vehicle with the jack. Risk of accident!

●

Never apply grease or oil to wheel nuts or

to the wheel hub threads. Even if the bolts

have been tightened to the prescribed tor-

que, they could come loose while driving.

●

Never loosen the screwed joints of wheel

rims with bolted ring trims.

●

If wheel nuts are tightened below the

prescribed torque, the bolts and rims could

come loose while driving. If tightening tor-

que is too high, the wheel nuts or threads

can be damaged.

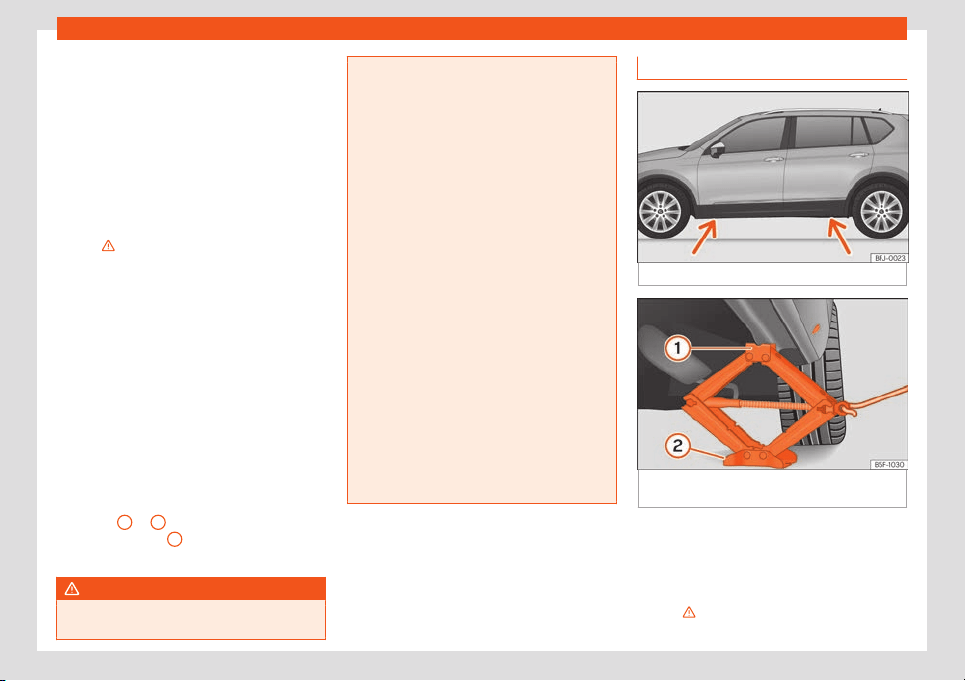

Raise the vehicle

Fig. 37

Jack position points.

Fig. 38

Cross member: positioning the jack on

the v

ehicle.

●

Rest the jack (vehicles tools) on firm

gr

ound. If necessary use a large, strong

board or similar support. If the surface is slip-

pery (for example tiles) place the jack on a

rubber mat or similar to prevent it from slip-

ping

›››

.

48

Loading ...

Loading ...

Loading ...