Loading ...

Loading ...

Loading ...

CHANGING THE NEEDLE

30

n

Carefully pull the end of the thread that was passed

through the eye of the needle.

* If a loop was formed in the thread passed through

the eye of the needle, carefully pull on the loop of

thread through to the back of the needle.

o

Raise the presser foot lever and pull out about 10 cm (4

inches) of the thread, and then pass it under the presser

foot toward the rear of the machine.

1 About 10 cm (4 inches)

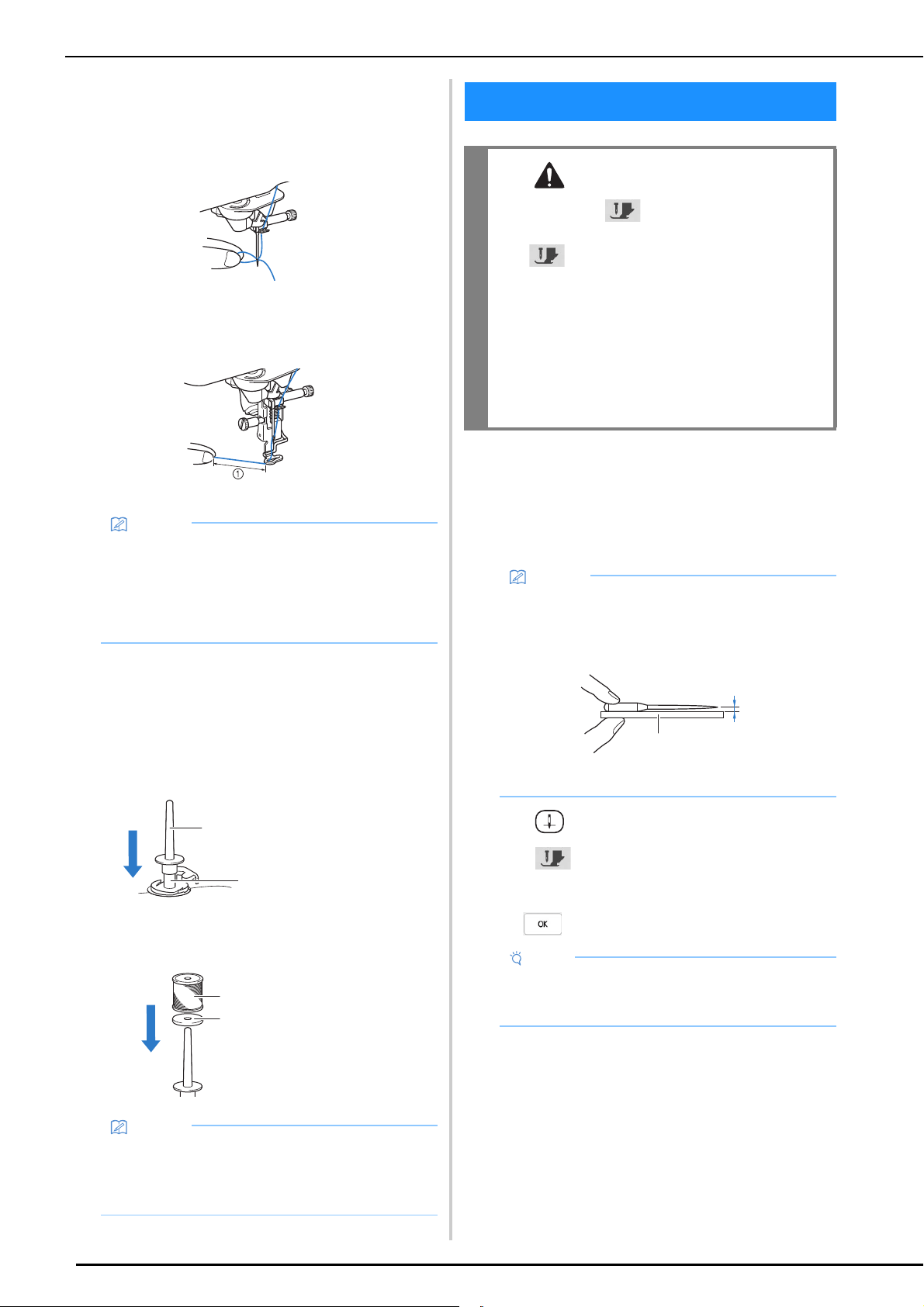

■ Using the Vertical Spool Pin

Use the vertical spool pin when using an irregularly

shaped thread spool, and when embroidering with

metallic thread.

a

Insert the vertical spool pin onto the bobbin winder

shaft.

b

Install the spool felt and the thread spool in that order,

and then thread the upper thread.

■ Thread and Needle Number

The lower the thread number is, the heavier the thread;

the higher the needle number, the larger the needle.

■ Embroidery Needles

Use a ball point needle 75/11.

a

Press (Needle position button) to raise the needle.

b

Press to lock all keys and buttons.

* If the message [OK to automatically lower the

presser foot?] appears on the LCD screen, press

to continue.

c

Remove the presser foot. (page 107)

Memo

• If the needle could not be threaded or the thread

was not passed through the needle bar thread

guides, perform the procedure again starting from

step

c.

Then, pass the thread through the eye of the

needle after step

i.

1 Bobbin winder shaft

2 Vertical spool pin

1 Spool felt

2 Thread spool

Memo

• When setting the thread spool, set it so that the

thread winds off from the front of the spool.

• This method keeps the thread from twisting as it

comes off the spool pin.

b

a

b

a

CHANGING THE NEEDLE

CAUTION

• Always press on the screen to lock all

keys and buttons before changing the needle.

If is not pressed and the “Start/Stop”

button or another operation button is pressed

accidentally, the machine will start and injury

may result.

• Use only home sewing machine needles. Other

needles may bend or break and may cause

injury.

• Never use a bent needle. A bent needle will

easily break and may cause injury.

Memo

• To check the needle correctly, place the flat side of

the needle on a flat surface. Check the needle from

the top and the sides. Throw away any bent

needles.

1 Parallel space

2 Flat surface (bobbin cover, glass, etc.)

Note

• Before replacing the needle, cover the hole in the

needle plate with fabric or paper to prevent the

needle from falling into the machine.

a

b

Loading ...

Loading ...

Loading ...