Loading ...

Loading ...

Loading ...

Installation

*INSTALLATION*

102

Ducting

If the vapour extraction is used

at the same time as a heating appli-

ance that relies on oxygen from the

same room, there is a risk of toxic

fumes.

It is essential that the “Warnings and

safety instructions” are observed.

The vapour extraction should be in-

stalled according to local and na-

tional building regulations. Seek ap-

proval from the building regulations

inspector where necessary.

The vapour extraction has an exhaust

duct of ⌀ 150mm.

Only use smooth pipes or flexible ex-

haust hoses made from non-flam-

mable materials for exhaust ducting.

To achieve the most efficient air

throughput with the lowest noise

levels, please note the following:

- The cross-section of the exhaust

ducting must not be smaller than the

cross-section of the exhaust connec-

tion (see the appliance dimensions).

- The ducting should be as short and

straight as possible.

- Only use wide radius bends.

- The exhaust ducting must not be

kinked or compressed.

- Ensure that all connections are

strong and airtight.

Remember that any constriction of

the air flow will reduce air throughput

and increase operating noise.

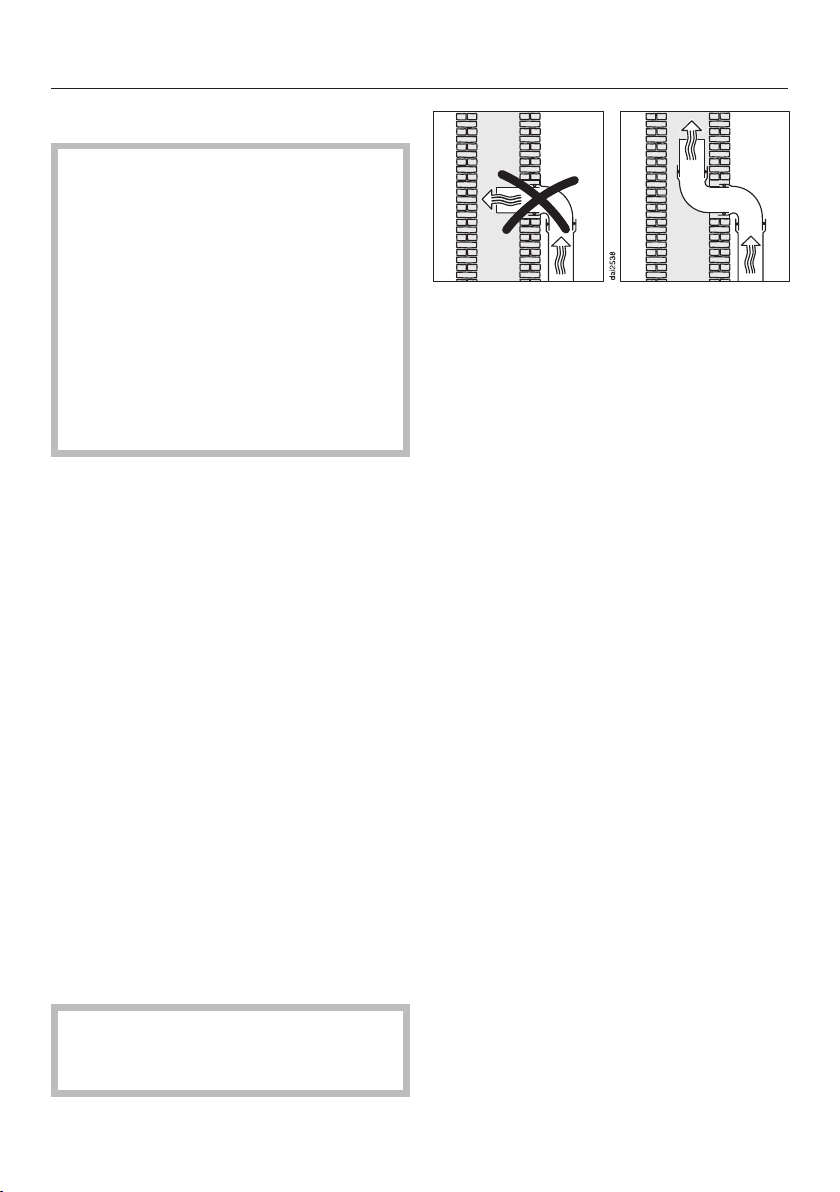

If the exhaust air is to be ducted into

a flue, the ducting must be directed in

the flow direction of the flue.

If ducting is to be laid horizontally it

must be laid with a downwards slop-

ing gradient. This is to ensure that

condensate cannot drain back into

the fan.

If the ducting is to run through cool

rooms, ceiling space, etc. there may

be great variations in temperature

between the different areas. The

problem of condensation will need to

be addressed. The ducting will need

to be suitably insulated.

Loading ...

Loading ...

Loading ...