Loading ...

Loading ...

Loading ...

Part number 550-100-211/0122

– 53 –

220 /29 9/3 00 /39 9

(see wiring diagram, Figure 65, page 59)(continued)

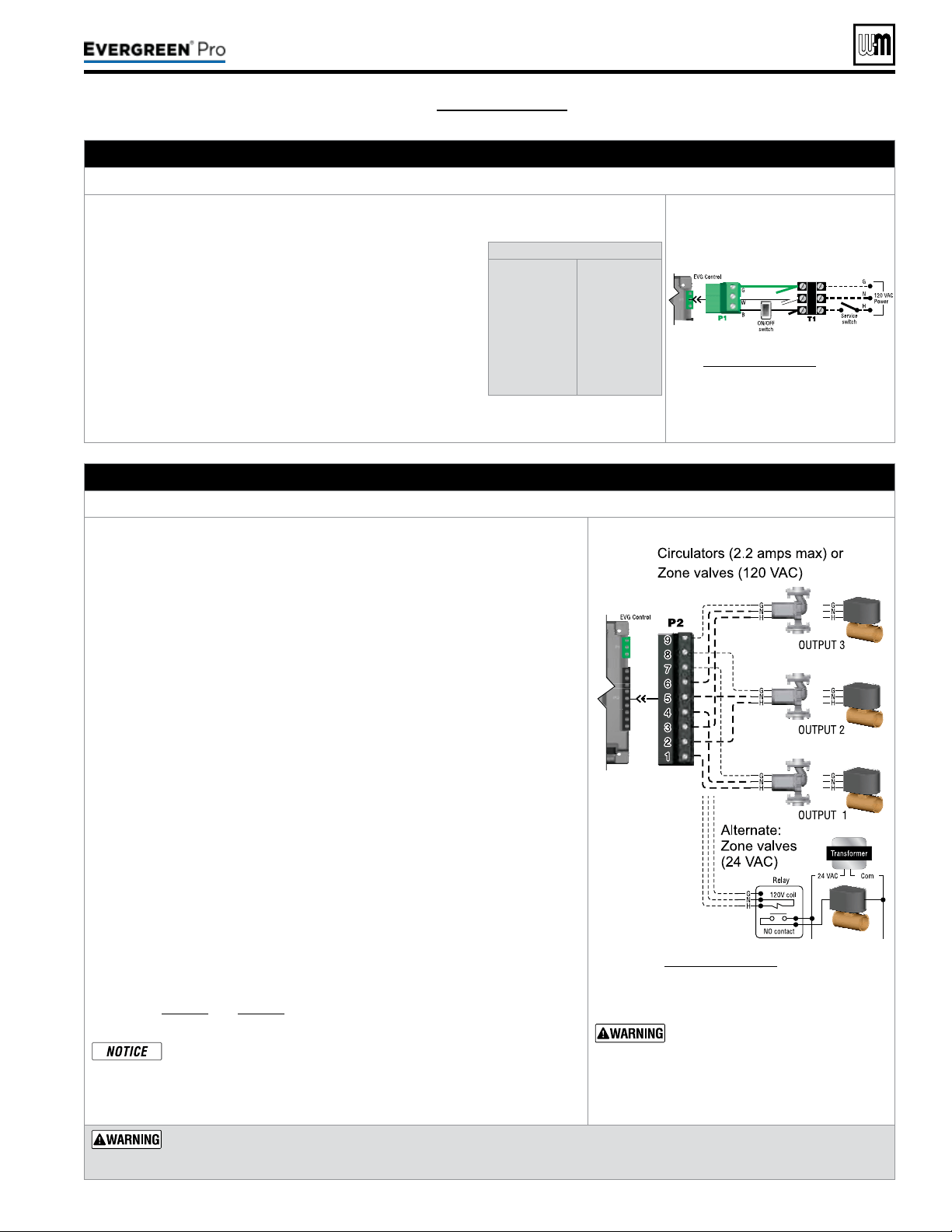

A. 120 VAC Power Supply – REQUIRED

TerminalBlockT1(control tray, right front)

1. Provide and install a properly-sized, fused disconnect or

service switch as required by applicable codes. (15-amp for

most cases.)

a. Use table at right to determine total load. Suggested

fused disconnect or service switch sizing is 15-amp if

total load is 12amps or less, 20-amp if total load is more

than 12amps.

2. Connect properly sized 120 VAC power wiring to Ever-

green

®

boiler line voltage terminal strip T1 as shown at right.

3. If possible, provide a surge suppressor in the supply power

line. is will reduce the possibilities of control damage due

to line surges.

4. Must wire ground to this terminal to provide boiler ground-

ing.

Determinetotalload

Boiler & boiler pump

(combined load)

Output 1 . . . . . . .

(2.2 amps max)

Output 2 . . . . . . .

(2.2 amps max)

Output 3 . . . . . . .

(2.2 amps max)

TOTAL . . .

. . . .

8.4 amps

____ amps

____ amps

____ amps

____ amps

See Figure65,page59 for details

B. 120VACOutputs1,2&3 – As needed for systems

TerminalStripP2(EVG control module, right side)

1. Output1: P2 Terminals 1 (H), 4 (N), 7 (G).

2. Output2: P2 Terminals 2 (H), 5 (N), 8 (G).

3. Output3: P2 Terminals 3 (H), 6 (N), 9 (G).

4. Maximum load: 2.2 amps (use relay if circulator load is higher). See WARN-

ING below.

5. ese three outputs (Output 1, Output 2, and Output 3) can provide 120VAC

to the following listed below.

y A zone

circulator.

y A system circulator.

y A DHW circulator (used to circulate through an indirect tank).

y An auxil

iary item that must be energized during an input call, such as

an air damper.

6. When using inputs/outputs for heat/DHW demands, each input (Input1,

Input2, and Input3) controls its respective 120VAC output (Output1, Out-

put2, and Output3). Outputs are energized only when BOTH conditions

below are met:

a. e corresponding input indicates a call for heat/DHW (i.e. contact

closure).

b. e PRIORITY assigned to the Input/Output pair is ACTIVE (i.e. the zone

may be calling but the pump won’t activate unless the boiler is currently

running on that system/priority).

7. When using the inputs/outputs for the AUX PUMP/OUTPUT function, the

output is controlled by selectable conditions set up in the control.

a. Use the AUX PUMP/OUTPUT function for devices such as system

pumps, combustion air dampers, and other auxiliary equipment to activate

when the boiler is on/running.

b. See page78 and page79 for more information on the setup and selection

of operating conditions.

ForPriorityDHWApplication:

e DHW aquastat can be connected to any one of the three input/

output pairs. e selected input should be assigned to PRIORITY1

during the WIZARD setup or manually in the ASSIGN INPUTS

menu.

See Figure65,page59 for details.

Output circuits are 120 VAC. If

an output is to operate a low

voltage circuit or must be an

isolated contact, use an isola-

tionrelay.

CIRCULATORPOWER — Themaximumallow-

ablecurrentforeachcirculatoris2.2amps

at120VAC

.

For circulators with higher amp ratings, install a circulator relay

or starter. Connect only the 120-VAC coil to the Evergreen

circulator terminals.

Loading ...

Loading ...

Loading ...