Loading ...

Loading ...

Loading ...

Allowablevent/airpipematerials&lengths

1. The concentric termination kit must be purchased

separately.

Use only the vent materials and kits listed in

Figure24,page21. Provide pipe adapters if

specied.

2. Locate the termination such that the total air piping and

vent piping from the boiler to the termination will not

exceed the maximum length given in Figure23,page20.

3. is termination requires a 45-degree elbow that is not

supplied with the termination kit. e maximum vent/

air pipe lengths include allowance for this elbow.

For polypropylene applications, comply with

any additional requirements in the vent system

manufacturer’s instructions. Provide 4” PVC-

to-PP transition pieces at the boiler vent and

air connections. PP adapter must have smooth,

straight section of pipe to insert in to the boiler

vent and air connections and must t and seal

tightly. PP adapters with their own seal which

would interfere with the internal seal of the

boiler vent or air connections must not be

used. Refer to page117 for a list of compliant

adapters. Install a locking collar at every joint.

For AL29-4C vent pipe applications, comply

with any additional requirements in the vent

system manufacturer’s instructions. Provide a

4”PVC transition at the boiler vent connec-

tion. Air pipe must be PVC or CPVC. Provide

transition pieces to PVC at the vent and air pipe

termination connections.

4. For 4” to 3” transitions, must use appropriate vent

material. For polypropylene or stainless steel must use

approved suppliers transitions (EVG 220 only).

Determineterminationlocation

Locate the concentric vent/air termination using the fol-

lowing guidelines:

1. Wall penetration thickness between 0” to 24”.

2. e concentric vent/air assembly must terminate as

shown in these instructions.

3. e termination must comply with the clearances and

limitations shown in Figure25,page23.

4. Locate the termination so it is not likely to be damaged

by foreign objects, such as stones or balls, or subject to

buildup of leaves or sediment.

5. For Canadian installations, follow requirements of

Natural Gas and Propane Installation Code, CAN/CSA

B149.1 or B149.2 and a ULCS636 compliant vent kit.

Multiplevent/airterminations

1. When terminating multiple Evergreen

®

boilers, install the

concentric vent/air termination assemblies as described

in this manual.

All vent outlets must terminate at the same

height to avoid possibility of severe personal

injury, death or substantial property damage.

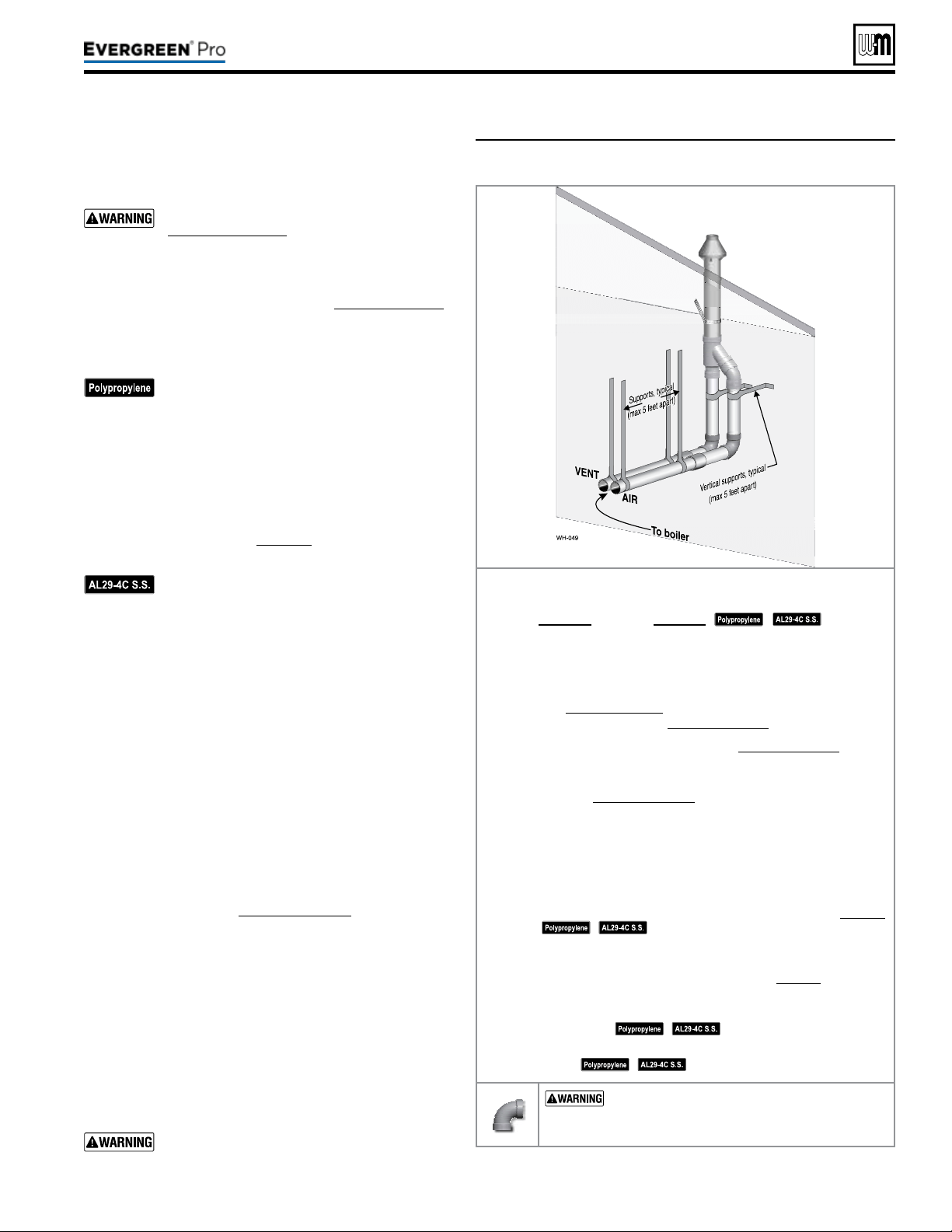

Figure39 INSTALLATIONSEQUENCE — Concentric vertical

Step1 Read and follow all instructions in this manual. DO NOT

proceedwithvent/airinstallationuntilyouhaveread

page19throughpage24.

See notices

at le.

Step2 Install the boiler in a location that allows proper routing of all

vent and air piping to the selected location.

Step3 Make sure the selected vertical termination location complies

with Figure25,page23. (Multiple boiler concentric terminations

must also comply with Figure40,page34.)

Step4 Use only the vent materials listed in Figure24,page21. Provide

pipe adapters where required.

Step5 Vent piping and air piping lengths must not exceed the values

shown in Figure23,page20.

Step6 e concentric termination must be assembled and installed

before piping from the boiler to the termination.

Step7 Prepare the vertical penetration(s) — assemble the concen-

tric termination kit and secure the penetration components

as instructed in this section. Provide the supports indicated

and mount the termination assembly. See “Prepare roof pen-

etrations” and “Mount concentric termination” on page34.

See notices at le.

Step8 Install vent and air piping between the boiler and the concentric

vent/air termination. Slope horizontal piping downward toward

the boiler at least 1/4 inch per foot. See page38 for general

guidelines.

Step9 Install pipe supports every 5 feet on both the horizontal and

vertical runs.

See notices at le.

Step10 Install a hanger support within 6inches of any upturn in the

piping.

See notices at le.

USESWEEPELBOWSFORALLVENTAND

AIR PIPING — DO NOT use short radius elbows

for vent or air piping. Boiler performance could be

aected.

Part number 550-100-211/0122

– 33 –

220 /29 9/3 00 /39 9

Loading ...

Loading ...

Loading ...