Loading ...

Loading ...

Loading ...

Part number 550-100-211/0122

– 109 –

220 /29 9/3 00 /39 9

Figure105 Troubleshooting suggestions for Evergreen

®

boilers — Faultdisplays,diagnosticsandcorrectiveactions

(continued)

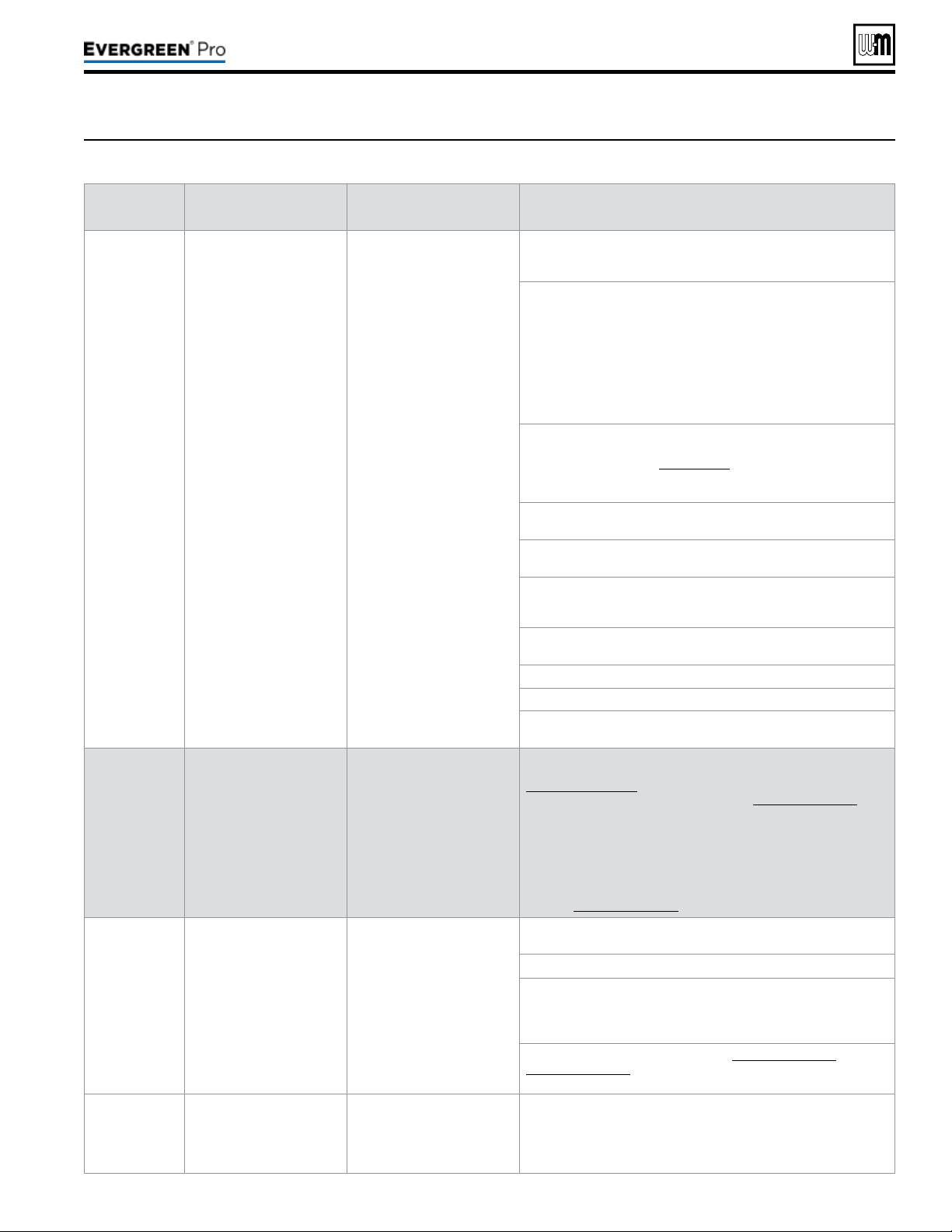

Display

Condition Diagnostics Corrective Action(s)

IGNITION

FAU LT

Boiler went through 5

ignition attempts and never

detected ame or ame

sense value never reached

minimum threshold for

boiler model.

Automatically resets after

1 hour or can be reset by

performing manual reset on

boiler.

Check condensate trap for blockage allowing condensate to

accumulate inside heat exchanger.

Check ignition cable connection.

Fouled, worn, bent, or faulty igniter.

Fouled igniters can be cleaned for additional use with steel wool.

Worn or badly fouled igniters should be replaced with the proper

repair part.

Igniter rods should be parallel with a 3.5 mm (0.138 in) spark gap.

NOTICE: Thin white deposits on the igniter are typical, but brown

or black deposits could be the result of ue gas recirculation.

Thoroughly inspect the venting system and termination for the

possibility of leakage or ue gas feedback into the air line.

Dirty burner and/or heat exchanger will cause high back pressure

and poor ignition.

Follow procedure in the Maintenance section of this manual to

clean burner and heat exchanger. Visual inspection of ueways

may not be sufcient to diagnose condition.

Check combustion settings on high and low re and adjust per

setup instructions if necessary.

Check incoming gas pressure with boiler off and at high re.

Adjust within limits on rating label.

Verify correct boiler model and altitude is selected in control and

correct elevation must be entered when operating above 2,00

feet.

Check ignition cable resistance. Should measure 1000 Ohms

(+/- 50 Ohms).

Check for ue pipe and intake pipe restrictions or blockage.

Check burner fasteners and gaskets.

Check venturi gaskets and proper venturi. (Propane models use

different venturi’s).

OUTDOOR

SENSOR ERROR

Outdoor temperature

sensor short or OPEN.

Will automatically reset if the

condition clears.

Warning only. Supply Max is

targeted until ODT is

restored, if used for target

adjustment.

Determine which sensors are suspect and measure their

resistance value and compare it to the values shown in

Figure 99, page 103. If the resistance values are incorrect

replace the temperature sensor. Refer to Replacement parts for

proper part number.

Check wire harness for loose connections and pin engagement

at sensor connection, chassis mount connection through control

housing, and the control. Unplug connection at sensor and at

control and check continuity between ends.

If problem persists after checking items above, replace control.

Refer to Replacement parts for kit number.

AIR PRESSURE

Switch Open

Occurs when Air Pressure

connection is open.

Reset using Manual Reset

screen on display.

High pressure in the exhaust

pipe or high vacuum in the

boiler intake or cabinet has

caused the air switch to

open. The switch is closed in

normal operating conditions.

Check boiler size selected in control against boiler rating label.

Correct if necessary to select the proper boiler size.

Check exhaust and intake pipe for restrictions or blockage.

Check condensate drain for blockage. If condensate is unable

to drain out of the boiler it can begin to block the ow of exhaust

gases. Clean the condensate collection area of the base and

condensate trap. Rell trap with fresh water.

Check the P7 connection as seen on Figure 65, page 59 &

Figure 66, page 60. Check the connections on the pressure

switch.

Closure Switch

fault

Proof of Closure

connections on P7 Pins 2

and 3 are open.

Soft lockout for 3½

minutes boiler retries. Each

consecutive failure adds 1

minute to lockout time, up to

6½ minutes maximum.

None - Check jumper on correct pins and secure connection.

Flow switch attached - Check correct pump is on, check wiring to

ow switch, and check switch is closing CAD - Check voltage to

damper. Check damper is opening.

Loading ...

Loading ...

Loading ...