Loading ...

Loading ...

Loading ...

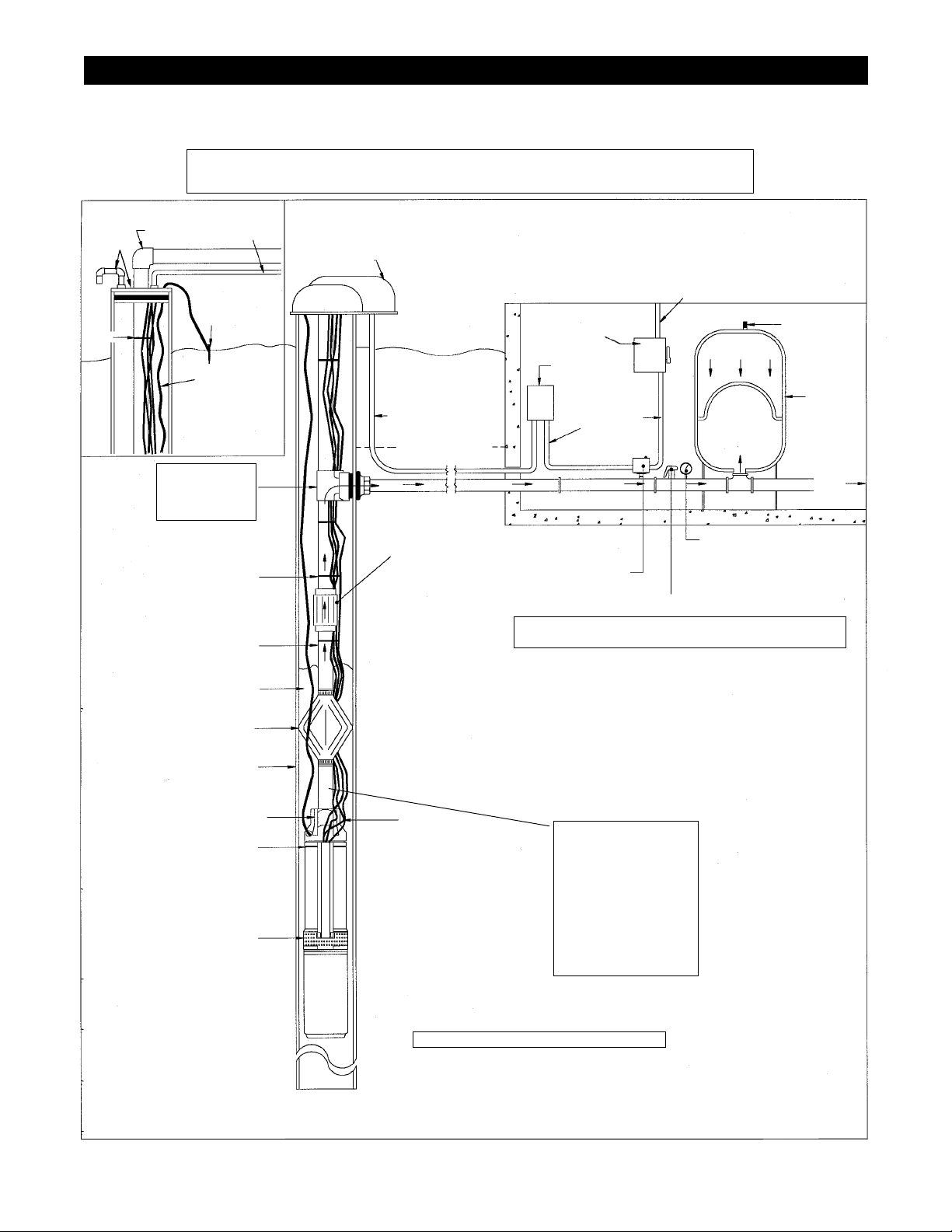

INSTALLATION

Figure 7 - Pump Installation

PICTORIAL OF 3-WIRE SYSTEM WITH AND WITHOUT A PITLESS ADAPTER

(SEE PAGE 10 FIGURE 9 IN THIS MANUAL FOR WIRING DIAGRAMS)

DISCHARGE PIPING REQUIREMENTS

• 5 gpm pumps 1" pipe

• 7 gpm pumps 1" pipe

• 10 gpm pumps 1" pipe is OK to 300 ft depth to water

• 10 gpm pumps 1¼" pipe if the depth to water exceeds 300 ft

CABLE

TIE

CONDUIT

FOR CABLE

IRON

ANCHOR

POST

VENTILATED

WELL CAP

SERVICE ENTRANCE

115 OR 230V

SUPPLY VOLTAGE

CONDUIT

TO SERVICE

FROST LINE

SPRING LOADED

CHECK VALVE

(RECOMMENDED

EVERY 200ft / 60 m)

CABLE TIE

OR TAPE

WELL CASING

POWER CABLES

AND GROUND

WIRE FROM

PUMP MOTOR

BUILT-IN CHECK VALVE

PUMP SUCTION

PUMP & MOTOR

DISCHARGE PIPE

(SEE NOTES BELOW)

NOTES

90º

ELBOW

POLY SAFETY

ROPE

Used to support weight of

the pump.

AIR VALVE

Pressurize tank @ 2

PSI below pressure

switch cut-in setting.

CAPTIVE AIR

PRESSURE

TANK

Offers

water storage

for fewer pump

cycles. Provides

air cushion to oper-

ate against. Tank

should be sized so

that draw down is

equal to capacity

of pump.

PITLESS ADAPTOR

INSTALLATION

For underground connection

of well pipe to horizontal pipe

providing a sanitary seal.

POLY SAFETY ROPE Used to

support weight of the pump.

TORQUE ARRESTOR

Absorbs thrust of motor start-ups.

Keeps pump centered in well. Various

types are available.

PRESSURE GAUGE Indicates systems

pressure at all times.

PUMP CONTROL

BOX Contains com-

ponents for three-wire

with ground motors.

CIRCUIT BREAKER

OR FUSED DISCONNECT

SWITCH

STANDARD PRESSURE SWITCH OR

"LOSS OF PRESSURE" SWITCH

Senses system pressure and automatically

turns pump on and off.

VENTED

WELL SEAL

Keeps debris

out of well.

TO PRESSURE PUMP TANK

If 1" semi-rigid plastic

pipe or steel pipe is

used, install 1¼" x 1"

reducer bushing

If 1" polyethylene pipe

is used, install 1" male

plastic pipe adapter,

along with 2 stainless

steel clamps

CONDUIT FOR PUMP

CABLE

Electric cable either three-wire

or two-wire with ground. Selec-

tion of proper size wire assures

required voltage to motor. (see

Table 1 page 3)

Use of Check Valves

Your pump is equipped with a built-in check located in the discharge head of the pump.

For deeper pump settings it is recommended that additional spring loaded inline check valves

be installed in the drop pipe @ 200 ft / 60 m intervals.

Check valves are used to hold pressure when the pump stops. They are also used to prevent

backspin, water hammer, and upthrust. Any of these three, or a combination of them, can

lead to immediate pump or motor failure, a shortened service life or operating problems

in the system.

PRESSURE RELIEF VALVE Protection against pressure buildup. Particularly vital where the

pump is capable of producing more pressure than the working limits of the tank.

WARNING! To prevent the possibility of dangerously high pressure, install a relief valve in

the discharge pipe between pump and flow restriction valve. Relief valve

must be capable

of passing full pump flow at 75 PSI.

8

Loading ...

Loading ...

Loading ...