Loading ...

Loading ...

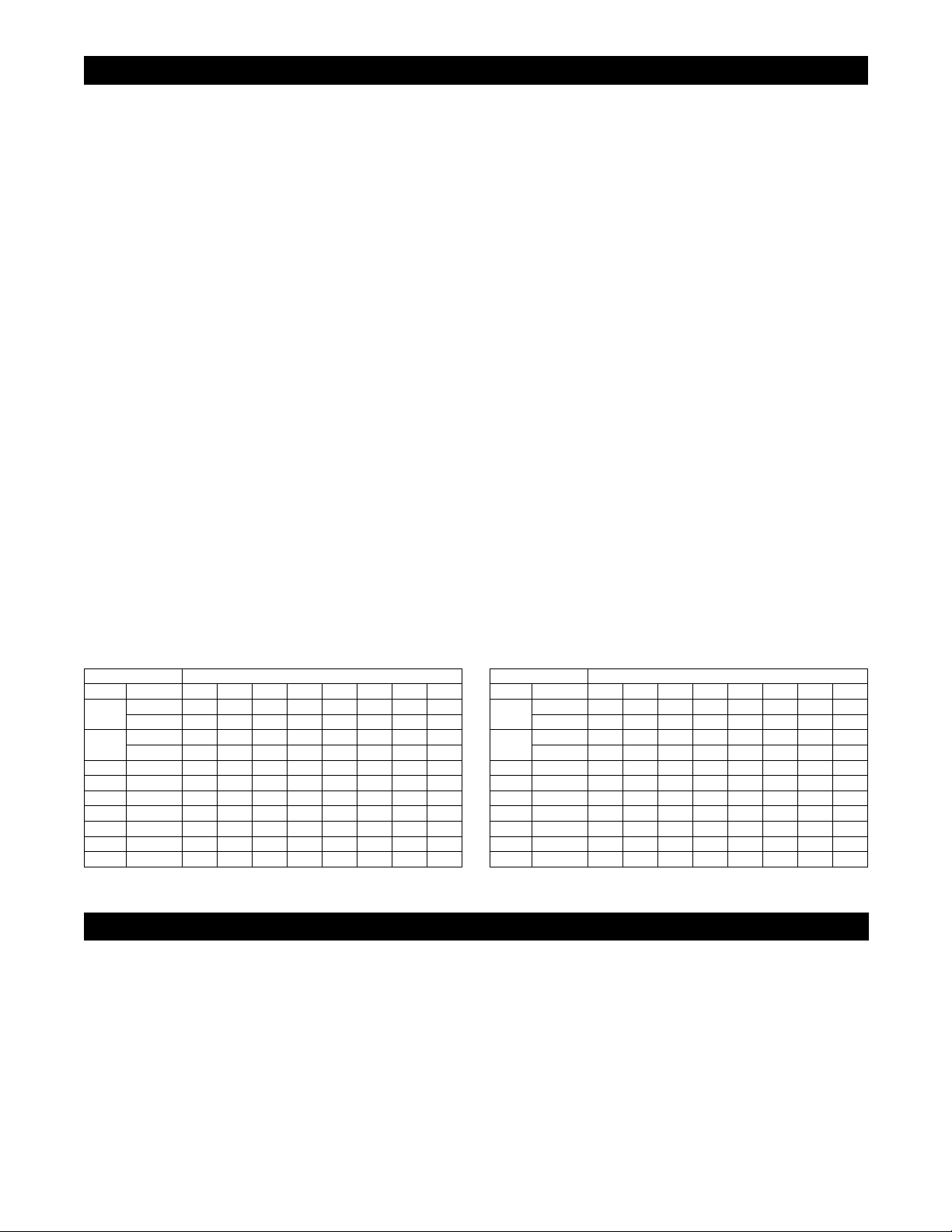

MOTOR (AWG) COPPER WIRE SIZE

HP VOLTS 14 12 10 8 6 4 3 2

1/3

115 130 210 340 540 840 1300 1610 1960

230 550 880 1390 2190 3400 5250 6520 7960

1/2

115 100 160 250 390 620 960 1190 1460

230 400 650 1020 1610 2510 3880 4810 5880

3/4 230 300 480 760 1200 1870 2890 3580 4370

1 230 250 400 630 990 1540 2380 2960 3610

1 1/2 230 190 310 480 770 1200 1870 2320 2850

2 230 150 250 390 620 970 1530 1910 2360

3 230 120 190 300 470 750 1190 1490 1850

5 230 0 0 180 280 450 710 890 1110

7 1/2 230 0 0 0 200 310 490 610 750

1 ft = .3048 meters

SAFETY INSTRUCTIONS

WARNING: General Precautions

o Review all the instructions before operating. Failure

to follow these instructions could cause bodily

injury and/or property damage.

o Though this pump is warranted to handle abrasives,

pumping sand continuously shortens the life of

the pump and motor and adversely affects their

performance. To prevent the above from occurring,

the pump and motor should be installed in fully

developed wells having the proper well screening

to prevent the pumping of abrasives.

o The pump and motor are water cooled and

lubricated, and should be sized and used in a

well that will provide adequate capacity to prevent

running dry. The pump is designed to run dry for

intermittent periods, but the motor is not.

o The pump, piping, and system must be protected

against freezing temperatures.

o Wear gloves and eye protection during assembly

and installation as precautionary safety measures.

o Never use in swimming pools or pool areas.

WARNING: Electrical Precautions

All wiring, electrical connections, and system

grounding must comply with the National Electrical

Code (NEC) and with any local codes and

ordinances. Employ a licensed electrician.

o A ground fault interrupter (GFI) protected circuit is

recommended for use with any electrical device

operating near water.

o Have a qualified electrician provide electrical power

to the motor. For cable sizes see Table 1.

o Make sure the line voltage and frequency of the

electrical current supply match the specifications

printed on the motor.

o Be sure leads and ground wires are properly water-

proofed and securely connected.

o Ensure the motor is properly grounded.

o Always disconnect the power before servicing.

o Never test a pump or use outside a well without

proper electrical grounding of the system.

Table 1 - (American) Cable selection

Based on a 5% Voltage drop

(Service entrance to motor - Maximum length in feet)

CAUTION: Use of smaller than recommended cable sizes

voids motor warranty!

Table 1 - (Canadian) Cable selection

Based on a 3% Voltage drop

(Service entrance to motor - Maximum length in feet)

CAUTION: Use of smaller than recommended cable sizes

voids motor warranty!

MOTOR (AWG) COPPER WIRE SIZE

HP VOLTS 14 12 10 8 6 4 3 2

1/3

115 75 125 205 325 505 780 965 1175

230 330 528 834 1314 2040 3150 3912 4775

1/2

115 60 95 150 235 370 575 715 875

230 240 390 610 965 1505 2325 2885 3525

3/4 230 180 285 455 720 1120 1735 2145 2620

1 230 150 240 375 595 925 1425 1775 2165

1 1/2 230 115 185 285 460 720 1120 1390 1710

2 230 90 150 235 370 580 915 1145 1415

3 230 70 115 180 280 450 715 895 1110

5 230 0 0 105 165 270 425 535 665

7 1/2 230 0 0 0 117 180 285 355 437

1 ft = .3048 meters

ASSEMBLY

TOOLS REQUIRED FOR ASSEMBLY

o Pipe wrenches

o Pipe vises or clamps

o PTFE tape

o Gloves and safety glasses

o CSA or UL approved PVC electrical tape

o Tripod with chain hoist or some other device to support

the unit while lowering it into the well

o Miscellaneous wrenches / tools as needed

3

Loading ...

Loading ...

Loading ...