Loading ...

Loading ...

Loading ...

• Install the well seal into the well casing by tightening

down cap screws on the well seal. The well seal

must be vented.

• Continue pipe connection to the tank location in the

house. Continue securing the submersible pump

cable to the pipe. Additional clamps and fittings will

be required to make the necessary connections at

the elbow and at the control center.

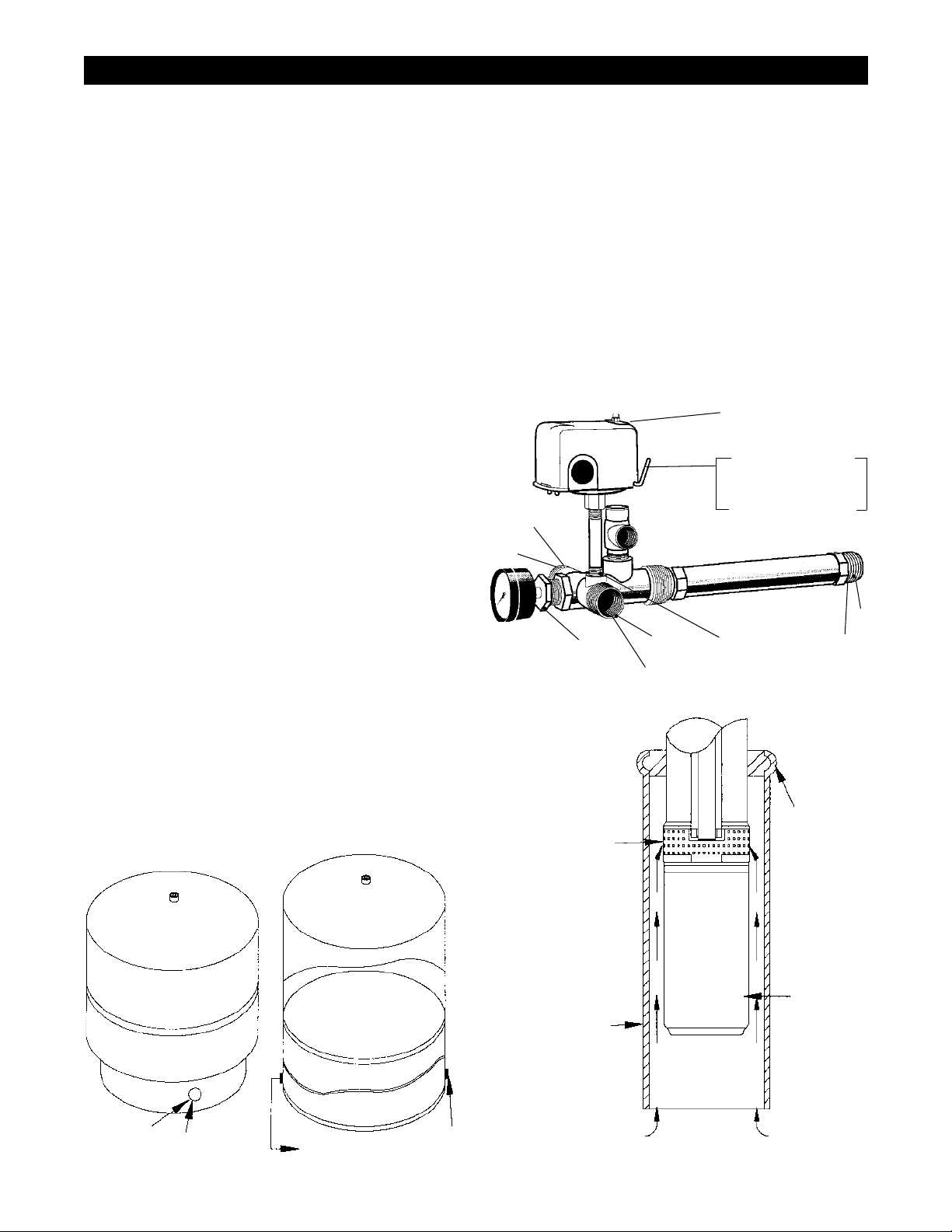

INSTALLING THE CONTROL CENTER

(Figure 5)

Note: PTFE tape must be used on all thread joints.

• Wrap the outside thread of the tank control center

with PTFE tape at position (A) and thread into tank

opening (see Figure 4). Control center will thread

directly into 1" opening in the side of the pre-

charged tank.

• Install the pressure gauge with a ¾" x ¼" bushing at

the opening marked position (B) on the control center.

• Install A pressure switch or “loss of pressure”

switch using ¼" x 3" nipple at the opening position

(C) in the control center.

• Connect pipe coming from well and pump

to position (E) in the control center using the

appropriate male plastic pipe adapter and clamp, if

polyethylene is used, or thread directly into control

center if ABS or steel pipe is used.

• Proceed from position (D) on the control center to

house service lines.

NOTE: The use of PTFE tape is recommended on all

threaded joints.

NOTE: It is recommended that the 1 hp and 1½ hp

models should not be installed where the pumping

level is less than 30 m (100 ft).

INSTALLATION

LAKE OR LARGE DIAMETER WELL INSTALLATION

All wiring, electrical connections, and system grounding

must comply with the National Electrical Code (NEC)

and with any local codes and ordinances. Employ a

licensed electrician.

If a pump is installed in a lake or large diameter well, a

flow inducer sleeve must be placed around the motor.

The sleeve should have an inside diameter of 4" to

6", and be composed of corrosion-resistant metal or

heavy plastic. The sleeve will ensure proper flow of

water around the motor for cooling purposes. The flow

inducer sleeve is closed off above the pump intake and

extends to the bottom of the motor or lower as shown

in Figure 6.

Figure 4 - Tank Openings

A

To Tank

Control Center

Float air

separator

To Tank

Control Center

1¼" Plug

Required

"Captive Air"

Precharged Tank

Epoxy or Glass Lined

Prechargeable Tank

Figure 5 - The Control Center

AUTO_

START_

OFF_

To Tank

Opening

A

C

E

To Pump

B

To Service

Line

D

Standard Pressure

Switch or "Loss of

Pressure Switch"

"Loss of Pressure

Switch" Illustrated with

Reset Lever

Figure 6 - Flow Inducer Sleeve

Flow Inducer

Sleeve

Water flows up the sleeve and

around the motor

Motor

Seal

Pump

Intake

7

Loading ...

Loading ...

Loading ...