Loading ...

Loading ...

Loading ...

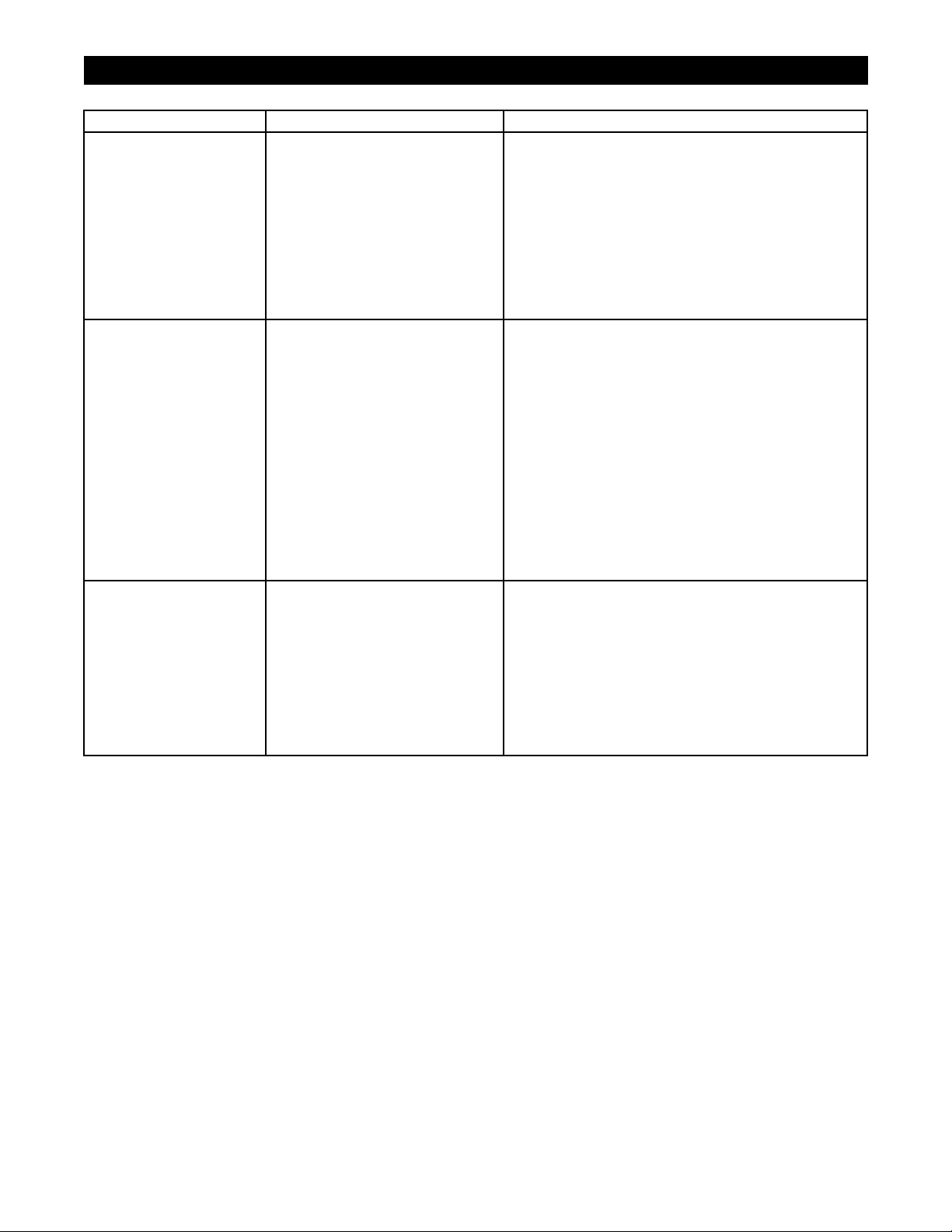

TROUBLESHOOTING

SYMPTOM CAUSE REMEDY

Motor will not start but does not

blow fuses.

WARNING! Hazardous voltage.

Can shock, burn, or cause death.

Employ a licensed electrician to

perform the wiring. All wiring

must be done in accordance with

applicable national and local

electrical codes.

1. No voltage to motor.

2. Cable splices or motor windings may be

grounded, shorted, or open-circuited.

3. Open circuit in pump control box (3-wire

only); faulty connections; faulty wires.

4. Faulty pressure switch.

5. 3-wire only; Cable leads improperly

connected in the control center.

1. With a voltmeter check; 1) fuse box to make sure full voltage is

available; 2) pressure switch terminals, to make sure pressure

switch is passing voltage correctly; and 3) terminal strips in pump

control box or disconnect switch box to make sure voltage is

available there. On 1½ through 3 hp: Push red overload reset

button(s) on the bottom of control center.

2. Consult certified electrician or service technician.

Do not attempt to disassemble pump or motor.

3. Examine all connections and wires; examine terminal strips in the

control center (3-wire only); repair if necessary.

4. Check pressure switch; replace if necessary.

5. Check wiring diagram on control center panel (or see Figure 9 on

Page 10 of this manual) and color coding of drop cable.

Pressure switch fails to shut

off pump.

1. Voltage is too low; motor will run slowly,

causing low discharge pressure (head)

and high operating current draw.

2. Faulty pressure switch.

3. Drop pipe is leaking.

4. Water level in the well may become too

low when pump is running.

1. Have a certified electrician verify voltage at the electrical disconnect

box (2-wire) or the pump control box (3-wire) while the pump is

operating. If the voltage is low, your power company may need to

raise it or installation may require larger wire. Discuss with the power

company or a certified electrician. Check voltage with a recording

meter if trouble reoccurs.

2. Replace switch.

3. Raise one length at a time until the leak is found. When water stands

in the pipe, there is no leak below this point.

4. Lower pump further into well, make sure it is between five and ten

feet from the bottom of the well. Install a valve into the discharge

pipe between the pump and the pressure tank. Use the valve

to restrict flow until discharge rate does not exceed the well

recovery rate.

WARNING! To prevent the possibility of dangerous high

pressure, install a relief valve in the discharge pipe between

the pump and flow restriction valve. The relief valve must be

capable of passing full pump flow at 75 psi.

Fuses blow or overload protector

trips when motor is running.

1. Low or high voltage.

2. 3-wire only: High ambient (atmospheric)

temperature.

3. 3-wire only: pump control box wrong

horsepower or voltage for installation.

4. Wire size is too small. Improperly

connected in the pump control box.

5. Cable splices or motor windings may be

grounded, shorted or open-circuited.

1. While the motor is running, voltage should not exceed plus 5% or

minus 5% of rated voltage shown on motor nameplate. Call your

power company to adjust line voltage if it is not within these limits.

2. Make sure the pump control box is installed out of direct sunlight.

3. Compare horsepower and voltage rating of motor (from motor

nameplate) with those of the pump control box (from pump control

box nameplate). These numbers must match.

4. See Table 1 on Page 3 of this manual and make sure the wire sizes

match specifications in the table.

5. Consult certified electrician or a service technician to determine if

this is the cause of the problem or not.

Do not attempt to disassemble pump or motor.

12

Loading ...

Loading ...

Loading ...