Loading ...

Loading ...

Loading ...

Weil-McLain 94 Series 3 Water and steam boilers — for Gas, Light Oil, & Gas/Light Oil-Fired Burners

16 Part No. 550-110-275/1018

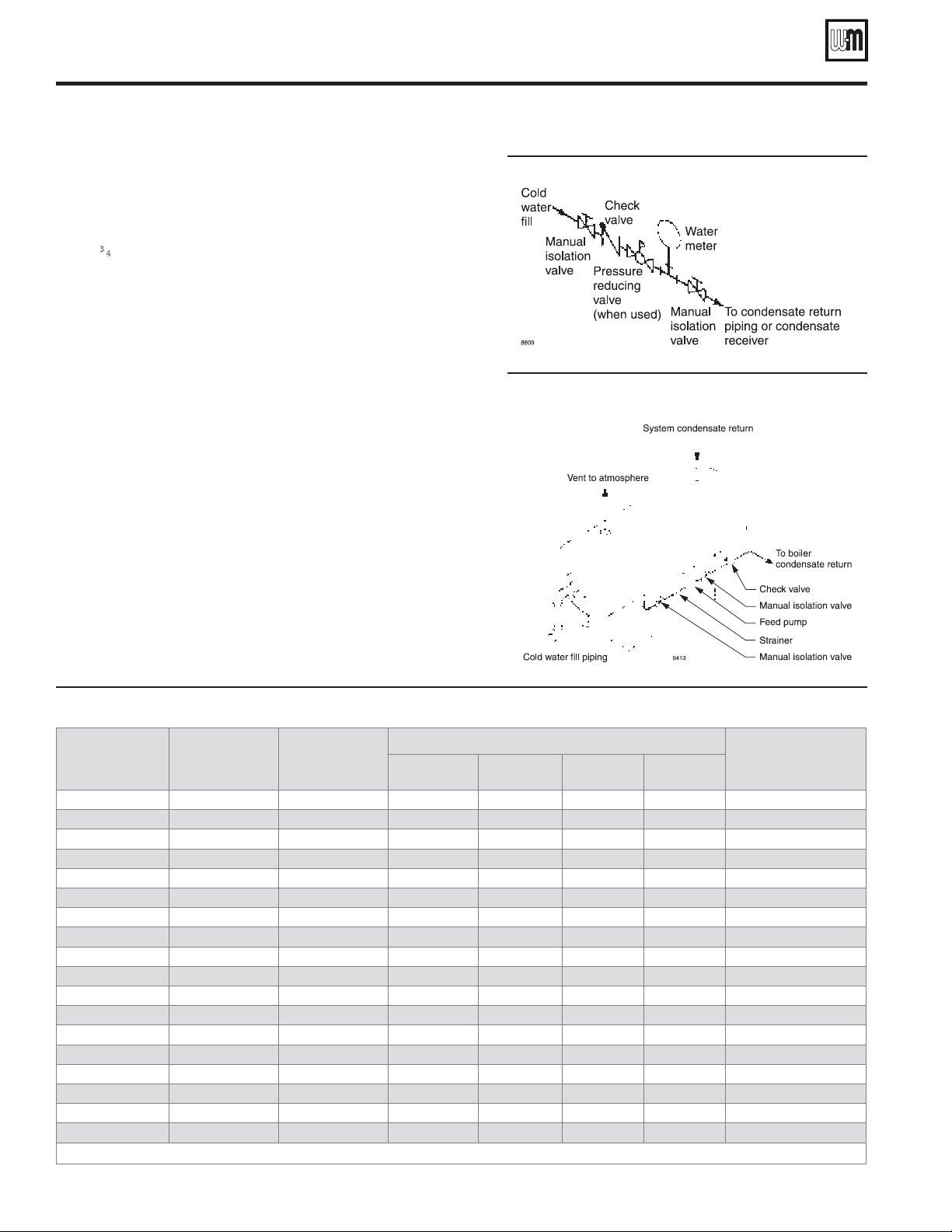

Connect steam boiler piping

Figure 18 Cold water fill piping

Figure 19 Condensate piping to boiler (see Figure 18

for cold water fill piping detail)

Boiler

model number

AHRI gross output

(lbs steam per hour)

Gallons condensate

per hour

Minimum condensate receiver capacity (gallons) (Note 1)

Recommended condensate

feed pump capacity

GPM at 15 PSI

15-minute boiler

operation

30-minute boiler

operation

45-minute boiler

operation

60-minute boiler

operation

894

2,028 244 74 148 222 296 8.0

994

2,320 279 84 168 252 336 9.0

1094

2,612 314 95 190 285 380 10.5

1194

2,904 349 105 210 315 420 12.0

1294

3,190 383 115 230 345 460 13.0

1394

3,480 418 126 252 378 504 14.0

1494

3,770 453 136 272 408 544 15.0

1594

4,070 489 147 294 441 588 16.5

1694

4,360 524 158 316 474 632 17.5

1794

4,650 559 168 336 504 672 19.0

1894

4,940 594 179 358 537 716 20.0

1994

5,230 628 189 378 567 756 21.0

2094

5,520 663 199 398 597 796 22 0

2194

5,810 698 210 420 630 840 22.0

2294

6,100 732 220 440 660 880 24.0

2394

6,390 767 231 462 693 924 26.0

2494

6.680 802 241 482 723 964 27.0

2594

6,970 837 252 504 756 1,008 28.0

Note 1 — Maximum time to when condensate returns to boiler — the longer the time for condensate to return, the larger the receiver must be.

Figure 20 Condensate receiver capacity requirements

General steam piping information:

1. Hartford loop piping arrangement and wet return are required for

steam boilers. Use the Hartford loop for both pumped-return and

gravity-return systems.

2. Maintain 24-inch minimum from waterline to bottom of header

(86

3

⁄4" from bottom of section).

3. When using condensate receiver, feed pump must be energized by

boiler-mounted pump controller.

4. Install piping:

a. Install piping as shown on page 17 through page 18 for single

boilers. See page 19 for additional requirements when piping

multiple boilers.

b. Return pipe sizing.

• Pumped return — Size return piping by pump.

• Gravity return — Size gravity return same as Hartford loop

equalizer pipe size.

c. Drain valve — Install system drain valve in lowest part of

return piping close to boiler. See Figure 15, page 15, for sizing.

d. Cold water fill piping — Connect cold water fill piping as shown

in Figure 18. Also shown are recommended valves and water

meter, if used. Water meter will detect added makeup water,

indicating leaks in system.

e. Condensate return piping:

• Satisfactory operation of any steam heating system depends

on adequate return of condensate to maintain steady water

level.

• Avoid adding excessive amounts of raw make-up water.

• Where condensate return is not adequate, a low water cutoff

with pump control, condensate receiver, and condensate

boiler feed pump should be installed.

• See Figure 19 for piping and Figure 20 for sizing.

Loading ...

Loading ...

Loading ...