Loading ...

Loading ...

Loading ...

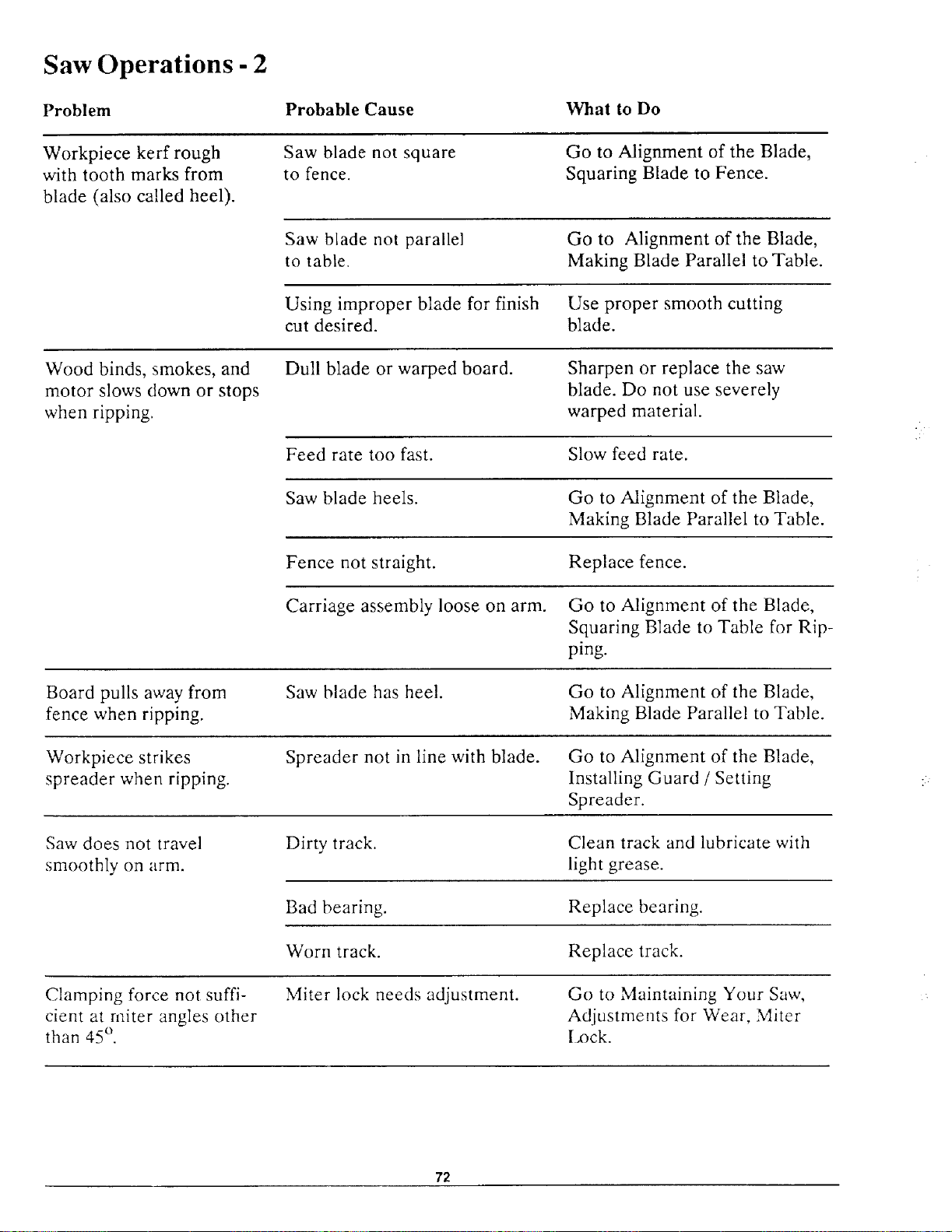

Saw Operations - 2

Problem Probable Cause

What to Do

Workpiece kerf rough

with tooth marks from

blade (also called heel).

Saw blade not square

to fence.

Go to Alignment of the Blade,

Squaring Blade to Fence.

Saw blade not parallel

to table.

Go to Alignment of the Blade,

Making Blade Parallel to Table.

Using improper blade for finish

cut desired.

Use proper smooth cutting

blade.

Wood binds, smokes, and

motor slows down or stops

when ripping.

Dull blade or warped board.

Sharpen or replace the saw

blade. Do not use severely

warped material.

Feed rate too fast. Slow feed rate.

Saw blade heels. Go to Alignment of the Blade,

Making Blade Parallel to Table.

Fence not straight. Replace fence.

Carriage assembly loose on arm. Go to Alignment of the Blade,

Squaring Blade to Table for Rip-

ping.

Board pulls away from

fence when ripping.

Saw blade has heel.

Go to Alignment of the Blade,

Making Blade Parallel to Table.

Workpiece strikes

spreader when ripping.

Spreader not in line with blade. Go to Alignment of the Blade,

Installing Guard / Setting

Spreader.

Saw does not travel

smoothly on arm.

Dirty track.

Clean track and lubricate with

light grease.

Bad bearing. Replace bearing.

Worn track. Replace track.

Clamping force not suffi- Miter lock needs adjustment.

dent at miter angles other

than 45 °.

Go to Maintaining Your Saw,

Adjustments for Wear, Miter

lock.

72

Loading ...

Loading ...

Loading ...