Loading ...

Loading ...

Loading ...

Making a Rip Cut Table Kerf

You will need to make a table kerf before a

rip cut can be made. Every time you move

the blade a new distance from the fence, you

will need to make a new kerf.

Blade Guard Adjustments

1. Unplug saw a_nd remove yellow ke_

2. Put saw in In-Rip position ano lOCKme

saw arm in the 0° position.

1. Put saw in desired rip position and lock the

saw arm in the 0° position.

2. Lock rip, swivel, miter, bevel and table

locks.

3. Adjust saw arm with handwheel until the

saw blade almost touches the table top.

4. Plug the saw into a grounded outlet.

5. Put on safety goggles.

6. Insert the yellow key in the red switch.

7. Turn saw on.

8. Lower saw blade until blade touches the

table.

9. Turn the handwheel about 1 full turn

more. This will make a 1/16 to 1/8 inch kerf

in the table.

_WARNING: For workpieces 1/4 inch

thick or less, make the rip kerr at least

1/8 inch deep to keep the saw blade

from rising up on top of workpieces and

violently throwing them.

10. Turn saw off and remove yellow key.

11. Unplug saw at the end of cutting session.

Adjustments for Ripping

,_1= DANGER: You will need to make

blade guard, anti-kickback pawls and

spreader adjustments before making a rip

cut.

Fig. 105- In-Rip Saw Position

3. Lock rip, miter, bevel, swivel and table

locks.

4. Go to the in-feed end of the saw blade.

Fig. 101.

5. Put the workpiece on the table, in line with

blade and under the nose of blade guard, so

it touches the blade.

6. Loosen the guard clamp screw and rotate

the guard until the guard nose just clears the

workpiece. Fig. 103.

7. Tighten the gnard clamp screw.

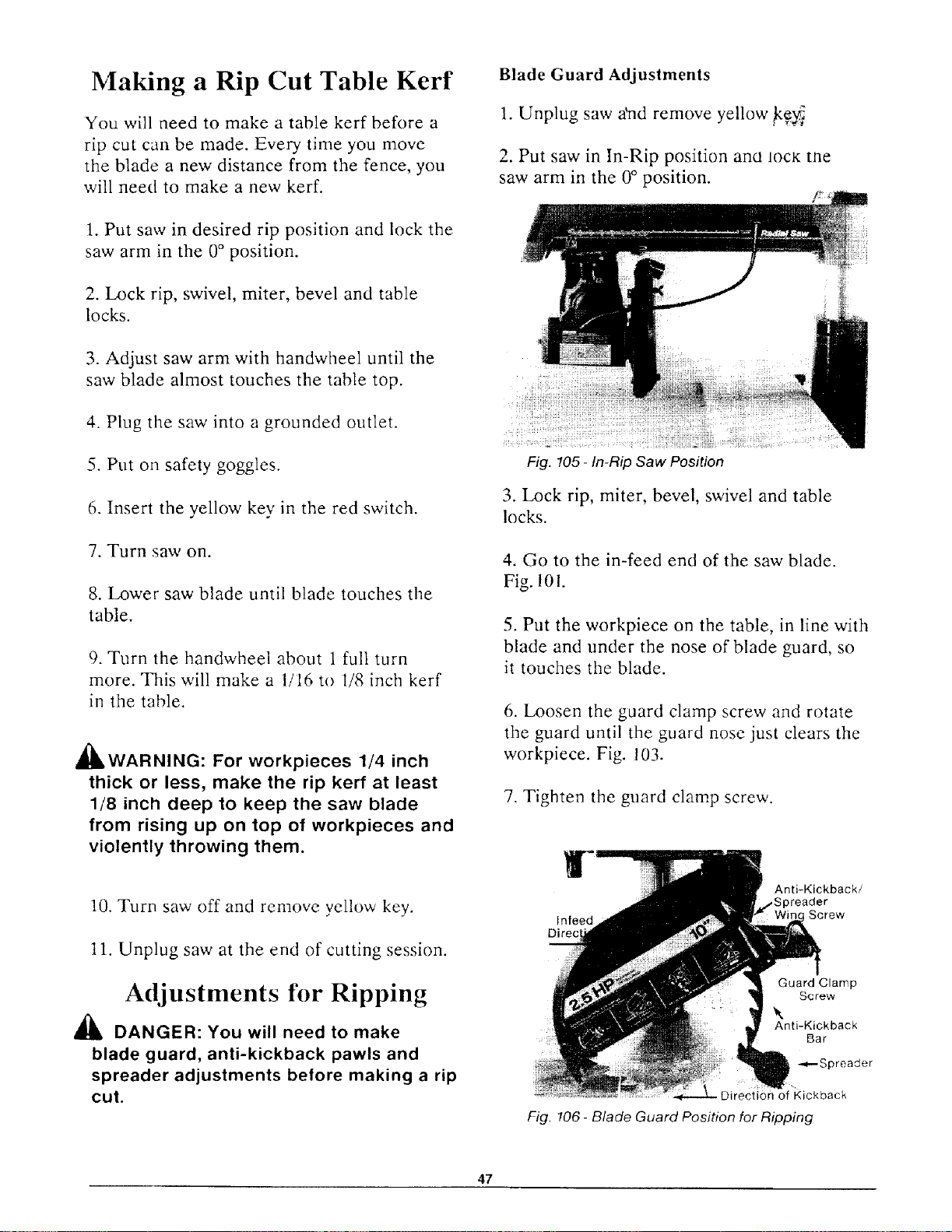

Infeed

Direc

Anti-Kickback/

Screw

Guard Clamp

Screw

Anti-Kickback

Bar

_n of Kickback

Fig. 106 - Blade Guard Position for Ripping

47

Loading ...

Loading ...

Loading ...