Loading ...

Loading ...

Loading ...

i i

+

Alignment of the Blade

ALIGNMENT OF THE BLADE IS THE

MOST IMPORTANT STEP IN

ASSEMBLING YOUR RADIAL ARM

SAW.

The blade of your radial arm saw must be

aligned properly for two reasons: to make

cuts accurate, and to prevent binding of the

blade and workpiece which can cause jams or

thrown workpieces.

These adjustments must be done in order,

before using your saw for the first time. If

they are not done in order the saw will not

cut accurately. If you miss an adjustment, you

must go back to the adjustment you missed

and repeat all steps from that point on.

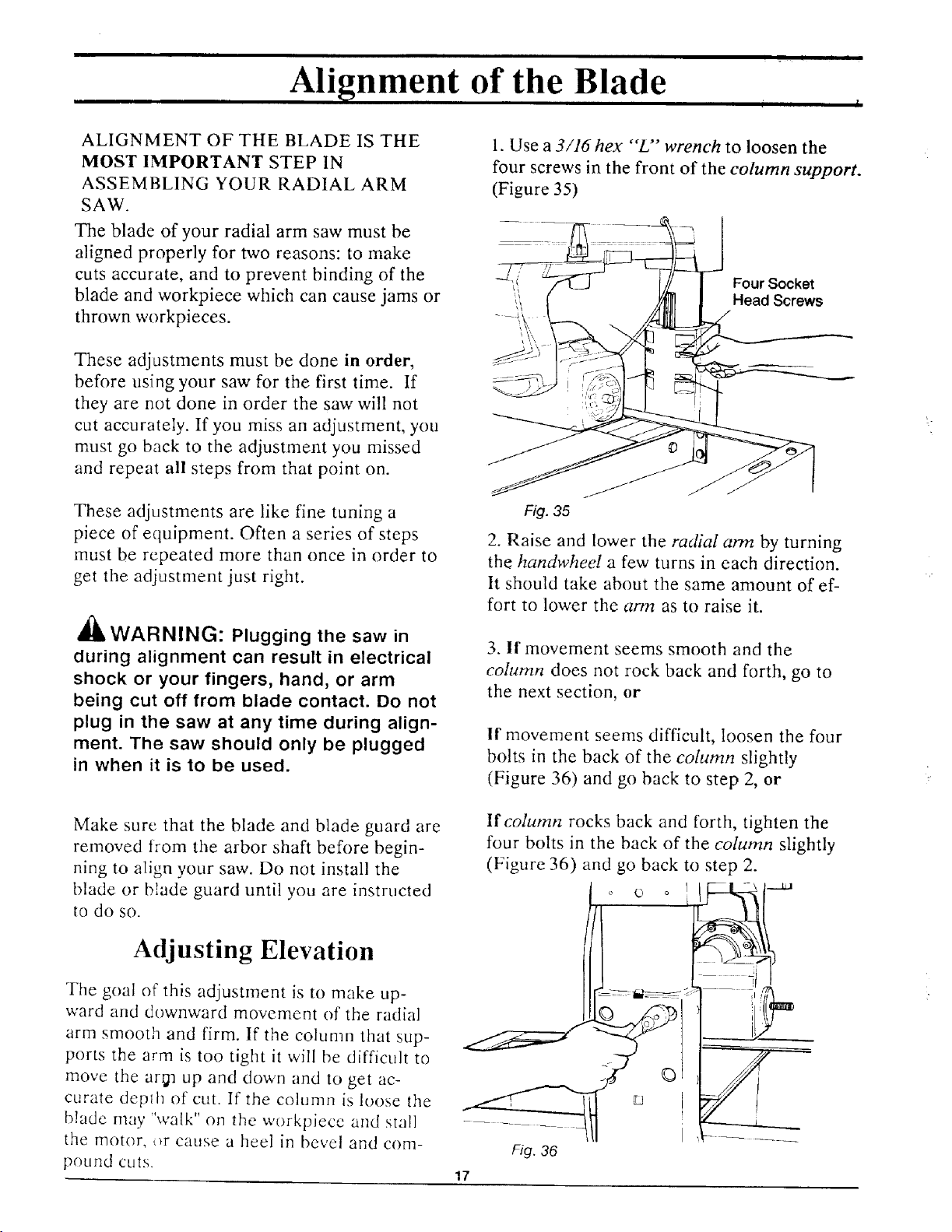

1. Use a 3/16 hex "'L'" wrench to loosen the

four screws in the front of the column support.

(Figure 35)

Four Socket

, Head Screws

These adjustments are like fine tuning a

piece of equipment. Often a series of steps

must be repeated more than once in order to

get the adjustment just right.

,WARNING: Plugging the saw in

during alignment can result in electrical

shock or your fingers, hand, or arm

being cut off from blade contact. Do not

plug in the saw at any time during align-

ment. The saw should only be plugged

in when it is to be used.

Fig. 35

2. Raise and lower the radial arm by turning

the handwhee! a few turns in each direction.

tt should take about the same amount of ef-

fort to lower the arm as to raise it.

3. If movement seems smooth and the

column does not rock back and forth, go to

the next section, or

If movement seems difficult, loosen the four

bolts in the back of the column slightly

(Figure 36) and go back to step 2, or

Make sure that the blade and blade guard are

removed from the arbor shaft before begin-

ning to align your saw. Do not install the

blade or blade guard until you are instructed

to do so.

Adjusting Elevation

The goal or" this adjustment is to make up-

ward and downward movement of the radial

arm smooth and firm. If the column that sup-

ports the arm is too tight it will be difficult to

move the ar_ up and down and to get ac-

curate deplh of cut. If the column is loose the

blade may "walk" on the workpiece and stall

the motor, or cause a heel in bevel and com-

pound cuts.

If column rocks back and forth, tighten the

four bolts in the back of the column slightly

(Figure 36) and go back to step 2.

o o I "

Fig. 36

17

Loading ...

Loading ...

Loading ...