Loading ...

Loading ...

Loading ...

17

SERVICE AND MAINTENANCE

Front Axles (If Equipped)

Each end of the tractor’s front pivot bar may

be equipped with a grease fitting. Lubricate

with a No. 2 multi-purpose grease applied

with a grease gun per the Maintenance

Schedule. See Figure 27.

Spark Arrestor Maintenance

(If Equipped)

Spark arrestor assemblies must be inspected

and cleaned periodically (see the service

interval chart in this manual). Visually inspect the screen for tears, broken wires or loose

welds. Replace the spark arrestor assembly if any of these conditions exist. If the screen

is in good condition, clean the screen by brushing away loose dirt or carbon particles.

Tires

Keep the tires inflated to the recommended pressures. Improper inflation will shorten

the tire service life. See the tire side wall for proper inflation pressures. Refer to

maintenance schedule chart located in this manual for proper service intervals.

Observe the following guidelines:

• Do not inflate a tire above the maximum pressure shown on the sidewall of the

tire.

• Do not reinflate a tire that has been run flat or seriously under inflated. Have it

inspected and serviced by a qualified tire mechanic.

Off-Season Storage

If your lawn tractor is not going to be operated for an extended period of time (thirty

days to approximately six months), the lawn tractor should be prepared for storage.

Store the lawn tractor in a dry and protected location. If stored outside, cover the lawn

tractor (including the tires) to protect it from the elements. The procedures outlined

below should be performed whenever the lawn tractor is placed in storage.

1. Change the engine oil and filter following the instructions provided in this

manual as well as the engine manual provided with this tractor.

WARNING

Never store the tractor with fuel in the tank indoors or in poorly ventilated

enclosures, where fuel fumes may reach an open flame, spark or pilot light as

on a furnace, water heater, clothes dryer, etc.

2. If storing the tractor for 30 days or more:

a. To prevent gum deposits from forming inside the engine’s carburetor

and causing possible malfunction of the engine, the fuel system must

be either completely emptied, or the gasoline must be treated with a

stabilizer to prevent deterioration.

b. Using a fuel stabilizer for storage between 30 and 90 days:

• Read the product manufacturer’s instructions and

recommendations.

• Add to clean, fresh gasoline the correct amount of stabilizer for

the capacity of the fuel system.

• Fill the fuel tank with treated fuel and run the engine for 2-3

minutes to get stabilized fuel into the carburetor.

• Fuel left in the fuel tank deteriorates and will cause serious

starting problems.

c. Emptying the fuel system for storage of more than 90 days:

• Prior to putting the tractor in storage, monitor fuel consumption

with the goal of running the fuel tank empty.

• Run the engine until it begins to stall. Use the choke to keep

the engine running until all fuel in the carburetor has been

exhausted.

• Referring to the engine manual, drain the fuel from the

carburetor bowl.

3. Clean the engine and the entire tractor thoroughly.

Note: Using a pressure washer or garden hose is not recommended for cleaning your

tractor other than to clean the underside of the deck. It may cause damage to electrical

components, spindles, pulleys, bearings or the engine. The use of water will result in

shortened life and reduce serviceability.

4. Fully charge the battery, then disconnect the negative cable at the battery to

prevent possible discharge. Recharge the battery periodically when in storage.

Note: Remove the battery if exposed to prolonged periods of sub-freezing

temperatures. Store in a cool, dry location where temperatures are above freezing.

5. Lubricate all lubrication points.

Removing the Lawn Tractor from Storage

1. Check the engine oil.

2. Fully charge the battery and inflate the tires to the recommended pressure. See

tire side wall for proper tire inflation pressure.

3. Fill the fuel tank with clean, fresh gasoline.

4. Start the engine and allow to idle for a few minutes to ensure engine is operating

properly.

5. Drive the tractor without a load to make certain all the tractor systems are

functioning properly.

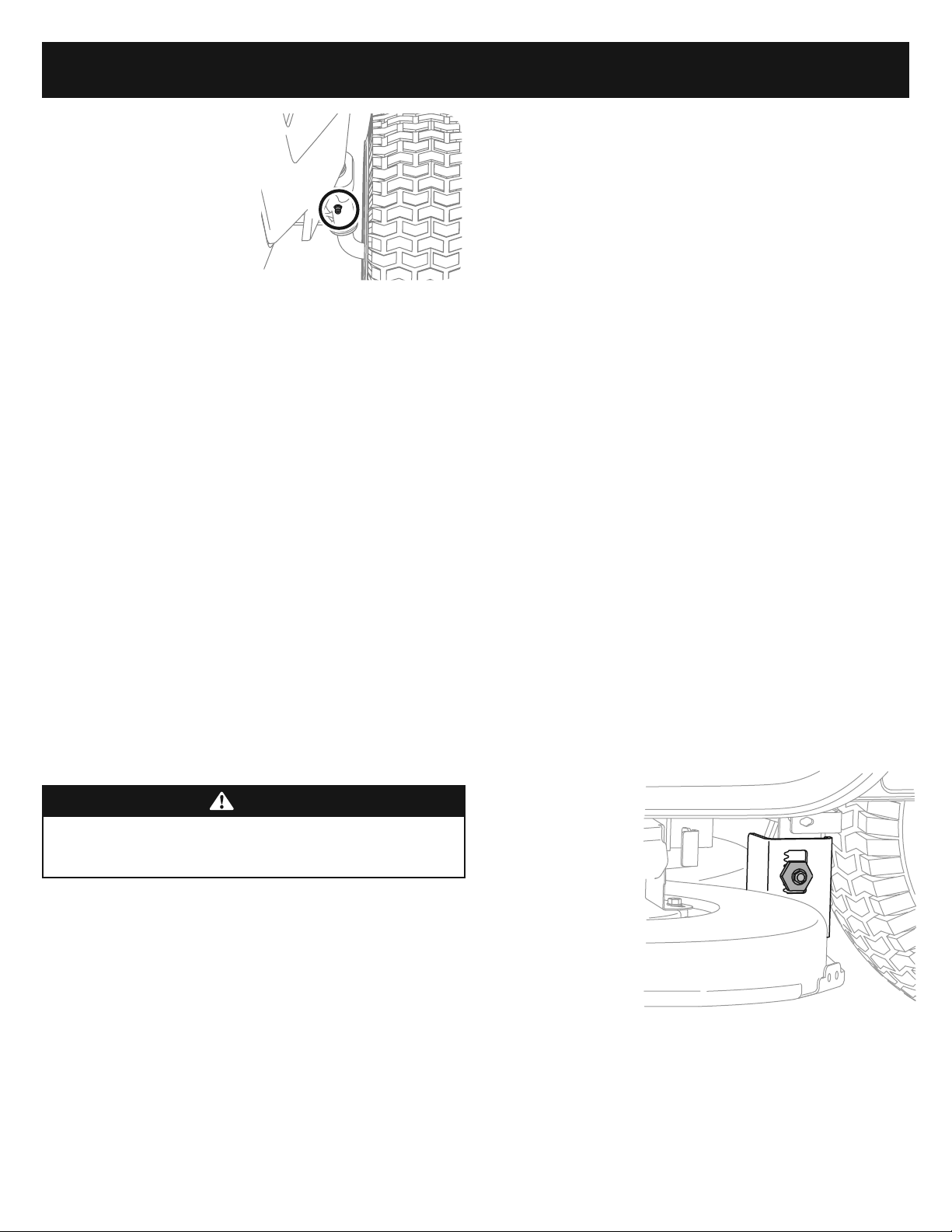

Leveling the Deck (Side-to-Side)

1. With the tractor parked on a firm, level surface, place the deck lift lever in the

second notch from the top (second highest position) and rotate both blades so

that they are perpendicular with the tractor.

2. Measure the distance from the outside of the left blade tip to the ground and the

distance from the outside of the right blade tip to the ground. Both measurements

taken should be equal. If they’re not, proceed to the next step.

3. Under the rear fenders inside the wheels there is a lift adjustment hex cap screw

and gear for each side of

the deck. See Figure 28.

4. Loosen, but do NOT

remove, the hex cap

screw (a) on the left deck

hanger bracket.

5. Minor adjustments

should be made to

the adjustment gear

immediately behind the

hex cap screw loosened

in the previous step

(clockwise/up or counter-

clockwise/down).

6. When the proper adjustment is achieved, tighten the hex cap screw (a) on the

left deck hanger bracket.

7. The deck is properly balanced when both blade tip measurements taken earlier

are equal.

Figure 27

(a)

Figure 28

Loading ...

Loading ...

Loading ...