Loading ...

Loading ...

Loading ...

Carburetor Adjustments & Tuning Tips

116

Adjustments for Competition

To assemble, reverse the disassembly procedures.

To install the carburetor, reverse the removal

procedures.

Tighten the following parts to the specified torque.

float bowl screws:

1.5 lbf·ft (2.1 N·m, 0.2 kgf·m)

float bowl plug:

3.6 lbf·ft (4.9 N·m, 0.5 kgf·m)

accelerator pump cover screws:

1.5 lbf·ft (2.1 N·m, 0.2 kgf·m)

carburetor top screws:

1.5 lbf·ft (2.1 N·m, 0.2 kgf·m)

jet needle/holder assembly:

1.3 lbf·ft (1.8 N·m, 0.18 kgf·m)

link arm torx screw:

1.5 lbf·ft (2.1 N·m, 0.2 kgf·m)

throttle drum cover bolt:

2.5 lbf·ft (3.4 N·m, 0.3 kgf·m)

hot start cable nut:

1.5 lbf·ft (2.1 N·m, 0.2 kgf·m)

throttle cable lock nut:

3.0 lbf·ft (4.0 N·m, 0.4 kgf·m)

leak jet:

0.2 lbf·ft (0.3 N·m, 0.03 kgf·m)

main jet:

1.1 lbf·ft (1.5 N·m, 0.2 kgf·m)

slow jet:

1.1 lbf·ft (1.5 N·m, 0.2 kgf·m)

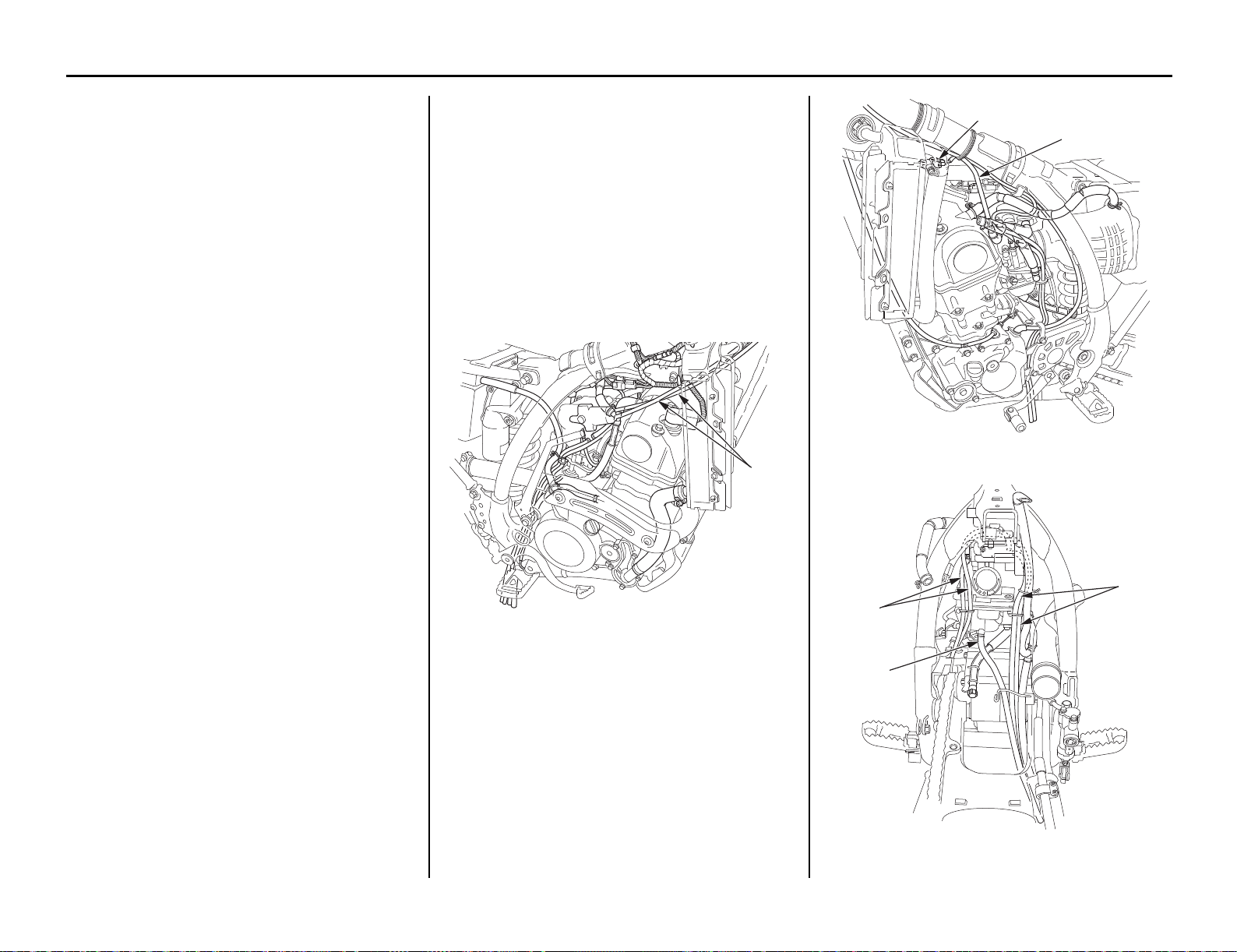

• Route the throttle cables (1), hot start cable (2)

and throttle position sensor wire correctly.

• After installing the carburetor, adjust the

throttle grip freeplay and hot start lever

freeplay.

• After installing the carburetor, check the

throttle position sensor connector (3) for

correct routing.

• After installing the carburetor, check the air

vent hoses (4) and overflow hose (5) for

kinking or pinching and correct routing.

• Check that the U-ring and O-ring are in good

condition. Replace them if necessary.

(1) throttle cables

(1)

(2) hot start cable

(3) throttle position sensor connector

(4) air vent hoses

(5) overflow hose

(3)

(2)

(5)

(4)

(4)

31KSE7100_NA.book 116 ページ 2019年4月9日 火曜日 午後1時13分

Loading ...

Loading ...

Loading ...