Loading ...

Loading ...

Loading ...

FDL (E2.1) 02/2019 page 46/76

The chamber is only active when the reset button (2b) is pushed in.

When the safety thermostat class 2 responds, the red alarm lamp (2a) illuminates, the reset button (2b)

pops out and the chamber turns off permanently at all poles. Only the fan keeps turning for safety rea-

sons.

Check the safety thermostat regularly and adjust it following changes of the set-point.

Fixed value operation: Adapt the temperature safety device every time the set-point for

temperature is changed. Set the set-point of temperature safety device by about 5 °C to 10 °C

above the controller temperature set-point.

Program operation: Adapt the temperature safety device to the highest temperature set-

point value of the program actually used.

Functional check:

Test the functional capability of the safety thermostat at appropriate intervals. It is recommended having

this check performed by the authorized service personnel, e.g. before the beginning of a long working

process.

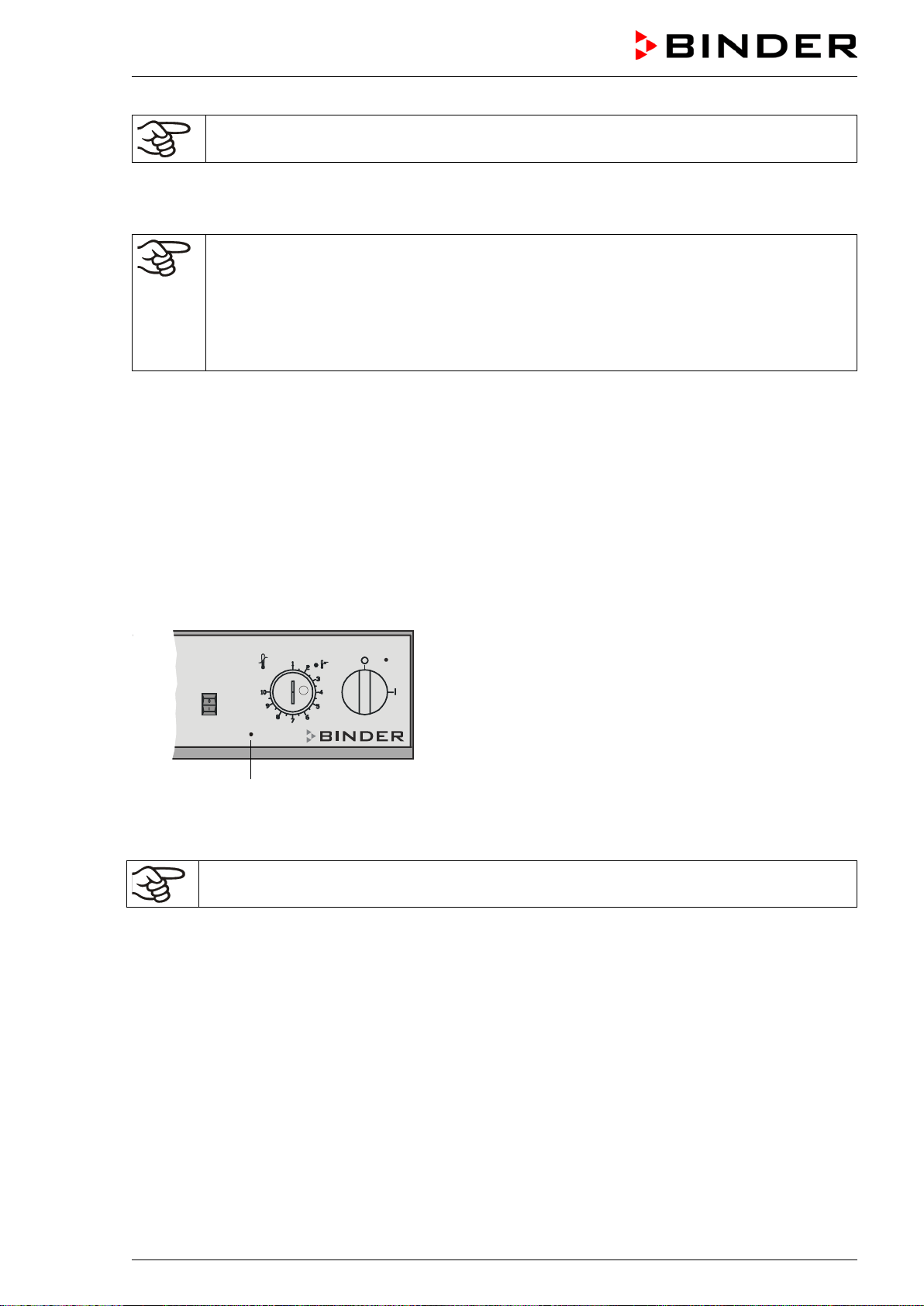

12.2 Exhaust air monitoring

If the volumetric flow rate of the exhaust air is too low, the heating and fan turn off immediately for safety

reasons. The indicator light “AIR” (3) lights up. As an additional indication there is an acoustical signal

which can be reset on the controller. The visual alarm message “RESET ALARM” on the controller is

shown until the next release of the heating.

(3)

(3) Red indicator light “AIR”: loss of technical ventilation

Figure 10: Instrument panel (detail)

It is the operator’s responsibility to ensure that the doors of drying ovens are opened immediately on fail-

ure of the technical ventilation system (GUV-R 500 chap. 2.28).

On failure of the technical ventilation, open the door of the safety drying oven.

AIR

START

Loading ...

Loading ...

Loading ...