Loading ...

Loading ...

Loading ...

FDL (E2.1) 02/2019 page 10/76

1.7 Operating instructions

Depending on the application and location of the chamber, the operator of the safety drying oven must

provide the relevant information for safe operation of the chamber in a set of operating instructions.

These operating instructions must be kept with the chamber at all times in a place where they

are clearly visible. They must be comprehensible and written in the language of the employ-

ees.

1.8 Measures to prevent accidents

During drying of fluid paints, flammable solvent/air mixtures can form and ignite.

The manufacturer took the following measures to prevent ignition and explosions:

• Indications on the type plate

See operating manual chap. 1.4

• Operating manual

An operating manual is available for each safety drying oven.

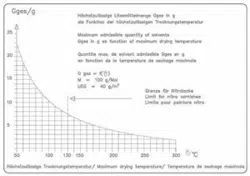

A diagram in the operating manual (chap. 2.3) indicates the maximum permissible solvent quantities

for various operating states.

The operating manual asks the operator of the safety drying oven to set up an instruction on the per-

missible loading quantity.

• Maximum temperatures and maximum permissible steam concentration

By means of the diagram “Highest permissible solvent quantity”, which is included in the operating

manual chap. 2.3 and applied on the front of the safety drying oven, the operator must adapt the drying

temperature to the maximum solvent quantity arising.

When using nitro-cellulose lacquers or nitro combination lacquers, the diagram ”Highest permissible

solvent quantity” specifies a limit temperature of max. 130 °C/ 266 °F, which must not be exceeded. (In

this context, all paints containing more than 5 % nitro-cellulose relative to the non-volatile contents are

regarded as nitro-cellulose lacquers and nitro-combination lacquers).

A gas-tight separation between the drying chamber and the heating chamber is not necessary since

there is an effective forced air motion in the entire steam room.

• Throttle valves

No throttle valves are used, i.e., the full air change occurs permanently.

• Protecting the heating surfaces against dripping

All heating elements are protected against lacquer dripping and direct contact with lacquer coatings.

• Heat insulation

All heat insulation is sealed against penetration by lacquer vapors from the outside with high tempera-

ture-resistant and ageing-resistant sealant.

The insulation material consists of non-combustible mineral wool (class A1 according to DIN 4102-

1:1998).

• Overtemperature monitoring

The safety drying oven is equipped with a temperature display, which can be read from outside.

A built-in additional temperature safety device can turn off the heating and is functionally independent

of the main controller. When turning off the chamber, the forced convection and the control equip-

ment’s function are maintained.

Visual (red indicator light) and audible (buzzer) signals indicate temperature exceeding.

Loading ...

Loading ...

Loading ...