Loading ...

Loading ...

Loading ...

122 Adjustments for Competition

Front Suspension Adjustments

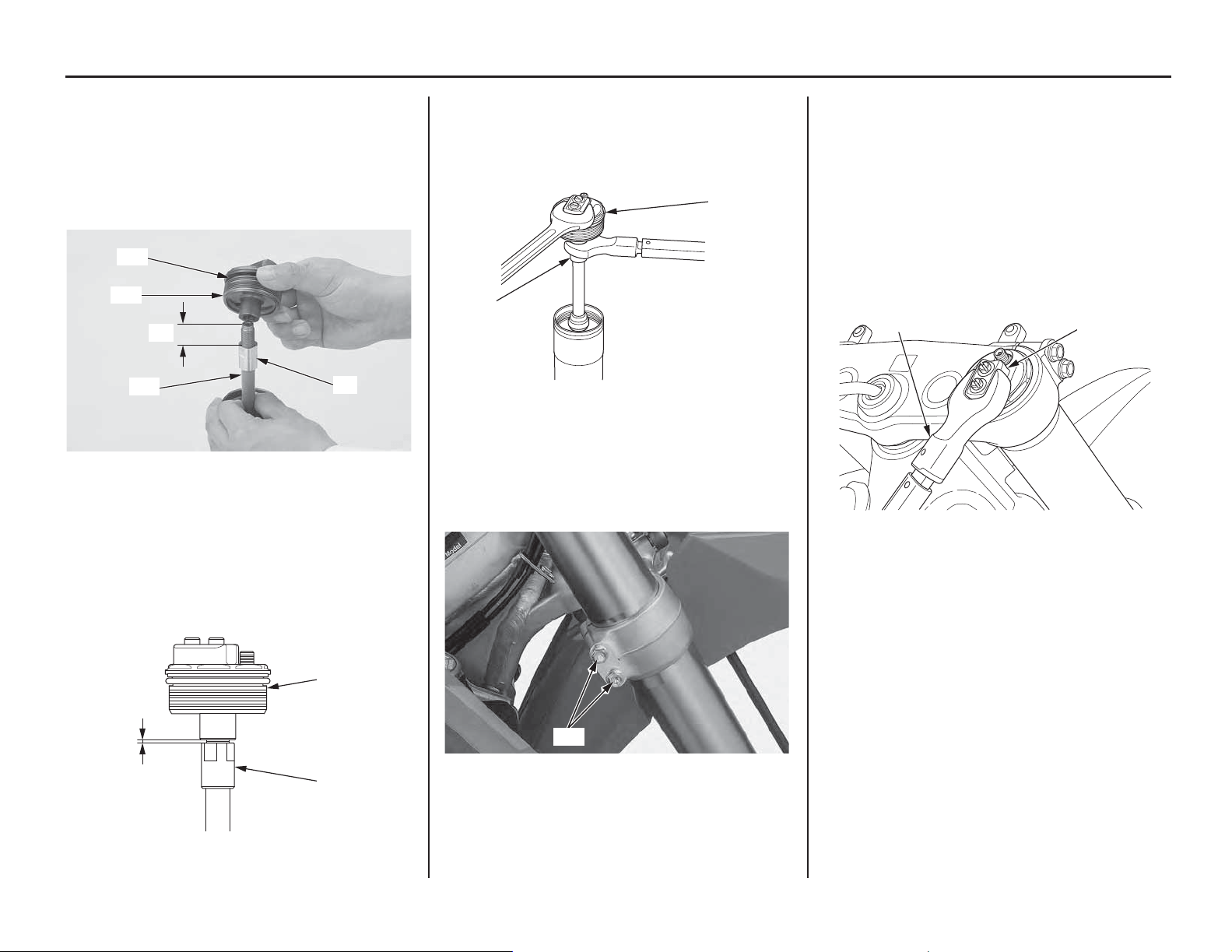

25. Tighten the fork damper lock nut (1) fully and

measure the thread length (A) as shown.

Standard: 0.7 – 0.8 in (19 – 20 mm)

26. Apply fork oil to the O-ring (11) and install it

to the fork cap (12). Install the fork cap to the

fork damper rod (10). Tighten the fork cap

fully by hand.

27. Measure the length of the fork damper lock nut

(1) and fork cap (12) clearance.

Standard: 0.04 – 0.08 in (1.0 – 2.0 mm)

If the clearance is out of specification, check the

fork damper lock nut and fork cap installation.

28. Tighten the fork damper lock nut (1) to the fork

cap (12) closely by hand. Tighten the fork

damper lock nut to the specified torque:

21 lbf·ft (29 N·m, 3.0 kgf·m)

29. Insert both fork legs into the fork clamps.

Tighten the fork bridge lower pinch bolts (13)

to the specified torque:

15 lbf·ft (20 N·m, 2.0 kgf·m)

30. Tighten the fork cap (12) to the specified

torque using the open end wrench (14):

Actual:

33 lbf·ft (45N·m, 4.6 kgf·m)

Torque wrench scale reading:

31 lbf·ft (42 N·m, 4.3 kgf·m)

The shape of the fork cap increases the torque

wrench’s leverage, so the torque wrench reading

will be less than the torque actually applied to the

fork cap.

31. Adjust the air pressure to specification.

Specified air pressure:

35 psi (240 kPa, 2.4 kgf/cm

2

)

(1) fork damper lock nut (A) thread length

(10) fork damper rod

(11) O-ring

(12) fork cap

(1) fork damper lock nut

(12) fork cap

(10)

(12)

(11)

(A)

(1)

(12)

(1)

(1) fork damper lock nut

(12) fork cap

(13) fork bridge lower pinch bolts

(12)

(1)

(13)

(12) fork cap

(14) open end wrench

(12)

(14)

Loading ...

Loading ...

Loading ...