Loading ...

Loading ...

Loading ...

3-4

n

Whirlpool Smart All-In-One Washer & Dryer

COMPONENT TESTING

For Service Technician Use Only

DANGER

Electrical Shock Hazard

Only authorized technicians should perform

diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can result in

death or electrical shock.

TESTING WASHER COMPONENTS FROM THE

CONTROL

Before tesng any of the components, perform the following

checks:

• The most common cause for mis-diagnosed control failure

is poor connecons. Therefore, disconnecng, inspecng

and reconnecng wires will be necessary throughout test

procedures.

• All tests/checks should be made with a VOM or DVM

having a sensivity of 20,000 ohms-per-volt DC, or greater.

• Check all connecons before replacing components,

looking for broken or loose wires, failed terminals, or wires

not pressed into connectors far enough.

• IMPORTANT: Voltage checks must be made with all

connectors aached to the boards.

• Resistance checks must be made with power cord

unplugged or power disconnected, and with wiring harness

or connectors disconnected from the control.

• IMPORTANT: The following procedures may require the use

of needle probes to measure voltage. Failure to use needle

probes will damage the connectors.

TEST #1: Appiance Control Unit (ACU)

Power Check

This test checks for incoming and outgoing power to and from

Appliance Control Unit (ACU). This test assumes that proper

voltage is present at the outlet.

1. Unplug washer/dryer or disconnect power.

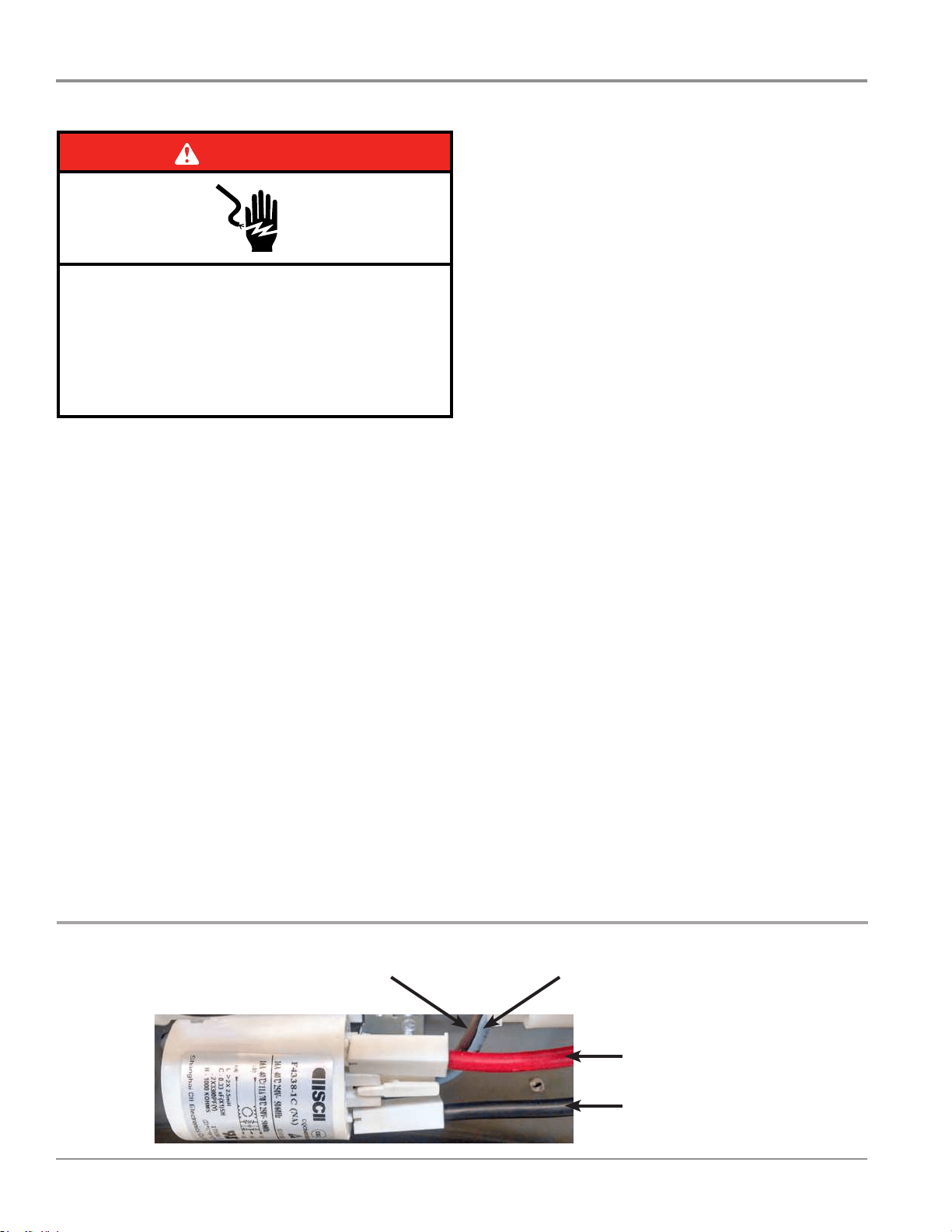

2. Visually check that all connecons to the RFI lter are

securely connected. See Figure 1, below.

3. Gently lay washer/dryer on its right side to access the

ACU. Remove AC shield and ACU cover.

4. Visually check that all connecons to the ACU are fully

inserted. See Figure 2, page 3-5.

5. If both visual checks pass, go to step 6.

6. Plug in washer/dryer or reconnect power.

7. With a voltmeter set to AC, check for line voltage at the

input of the RFI lter. See Figure 1.

¾ If line voltage is present, go to step 8.

¾ If line voltage is not present, verify the connuity of

the power cord. If it fails the connuity check, replace

the power cord.

8. With a voltmeter set to AC, check for line voltage at the

output of the RFI lter. See Figure 1.

¾ If line voltage is present, go to step 9.

¾ If line voltage is not present, replace the RFI lter.

9. With a voltmeter set to AC, check for input line voltage to

the ACU across pins 1 and 2 of connector J1. See Figure 2.

¾ If line voltage is present, go to step 10.

¾ If line voltage is not present, check harnesses and

connecons between the lter and the ACU. Visually

inspect inside connector housing for bent or damaged

terminals. Repair as necessary.

10. Check HMI input voltage:

With a voltmeter set to DC, verify that there is 12V

between pin 3 and 4 at J16.

¾ If there is 12V, go to step 11.

¾ If there is not 12V, disconnect J16 and recheck for 12V

between pin 3 and 4. If there is not 12V, replace the

ACU. If 12V returns, check ACU to HMI harness for

short. If harness is good, then replace the HMI.

11. Unplug washer/dryer or disconnect power.

12. Reassemble all parts and panels.

13. Perform the Service Diagnosc Mode Tests on page 2-3 to

verify repairs.

RFI FILTER - FIGURE 1

L2 Input to RFI Filter (Black Wire)

L2 Output to ACU J1, Pin 1 (Lt Blue Wire)L1 Output to ACU J1, Pin 2 (Brown Wire)

L1 Input to RFI Filter (Red Wire)

Loading ...

Loading ...

Loading ...