Loading ...

Loading ...

Loading ...

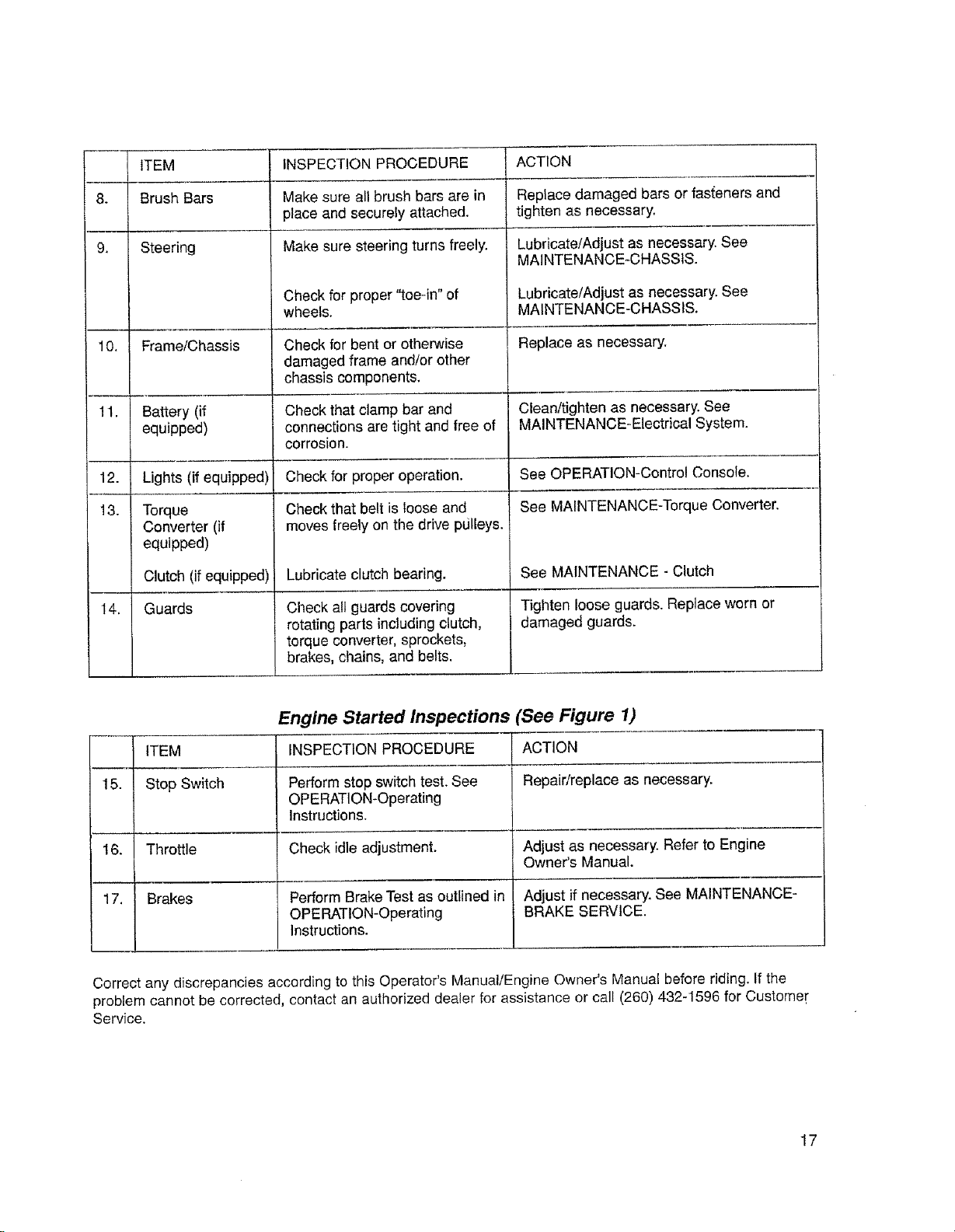

ITEM

BrushBars

Steering

FramelChassis

Battery(if

equipped)

Lights (if equipped)

Torque

Converter (if

equipped)

INSPECTION PROCEDURE

Make sure all brush bars are in

place and securely attached.

Make sure steering turns freely,

Check for proper "toe-in" of

wheels.

Check for bent or otherwise

damaged frame and!or other

chassis components.

Check that clamp bar and

connections are tight and free of

corrosion.

Check for proper operation.

Check that belt is loose and

moves freely on the drive pulleys.

ACTION

Replace damaged bars or fasieners and

tighten as necessary.

Lubricate/Adjust as necessary, See

MAINTENANCE-CHASSIS.

Lubricate/Adjust as necessary, See

MAINTENANCE-CHASSIS.

Replace as necessary.

Clean/tighten as necessary. See

MAINTENANCE-Electrical System.

See OPERATION-Control Console.

See MAINTENANCE-Torque Converter.

Clutch (if equipped) Lubricate clutch bearing. See MAINTENANCE - Clutch

Guards Check all guards covering Tighten loose guards. Replace worn or

rotating parts including clutch, damaged guards.

torque converter, sprockets,

brakes, chains, and belts.

Engine Started Inspections (See Figure 1)

ITEM INSPECTION PROCEDURE ACTION

Stop Switch Perform stop switch test. See Repair/replace as necessary.

OPERATION-Operating

Instructions.

Throttle Check idle adjustment. Adjust as necessary. Refer to Engine

Owner's Manual.

Brakes Perform Brake Test as outlined in Adjust if necessary. See MAINTENANCE-

OPERATION-Operating BRAKE SERVICE.

Instructions.

15

16

Correct any discrepancies according to this Operator's Manual!Engine Owner's Manual before riding. If the

problem cannot be corrected, contact an authorized dealer for assistance or call (260) 432-1596 for Customer

Service.

17

Loading ...

Loading ...

Loading ...