Loading ...

Loading ...

Loading ...

20

ALIGNMENTS AND ADJUSTMENT, Continued

IF THE OVEN BURNER DOES NOT IGNITE WITHIN 20 TO 60

SECONDS AFTER THE PILOT IS LIGHTED, TURN THE OVEN

TEMPERATURE CONTROL TO OFF AND WAIT FOR POWER TO BE

RESTORED. DO NOT ATTEMPT TO RELIGHT THE PILOT AGAIN.

If the oven does not function properly when the power is restored, or at any other time, call

a serviceman to determine the source of the problem. DO NOT ATTEMPT TO SERVICE

THE RANGE YOURSELF.

NEVER LEAVE THE CONTROL KNOBS IN ANY POSITION OTHER THAN

“OFF” IF THE IGNITORS OR BURNERS AREN’T WORKING PROPERLY.

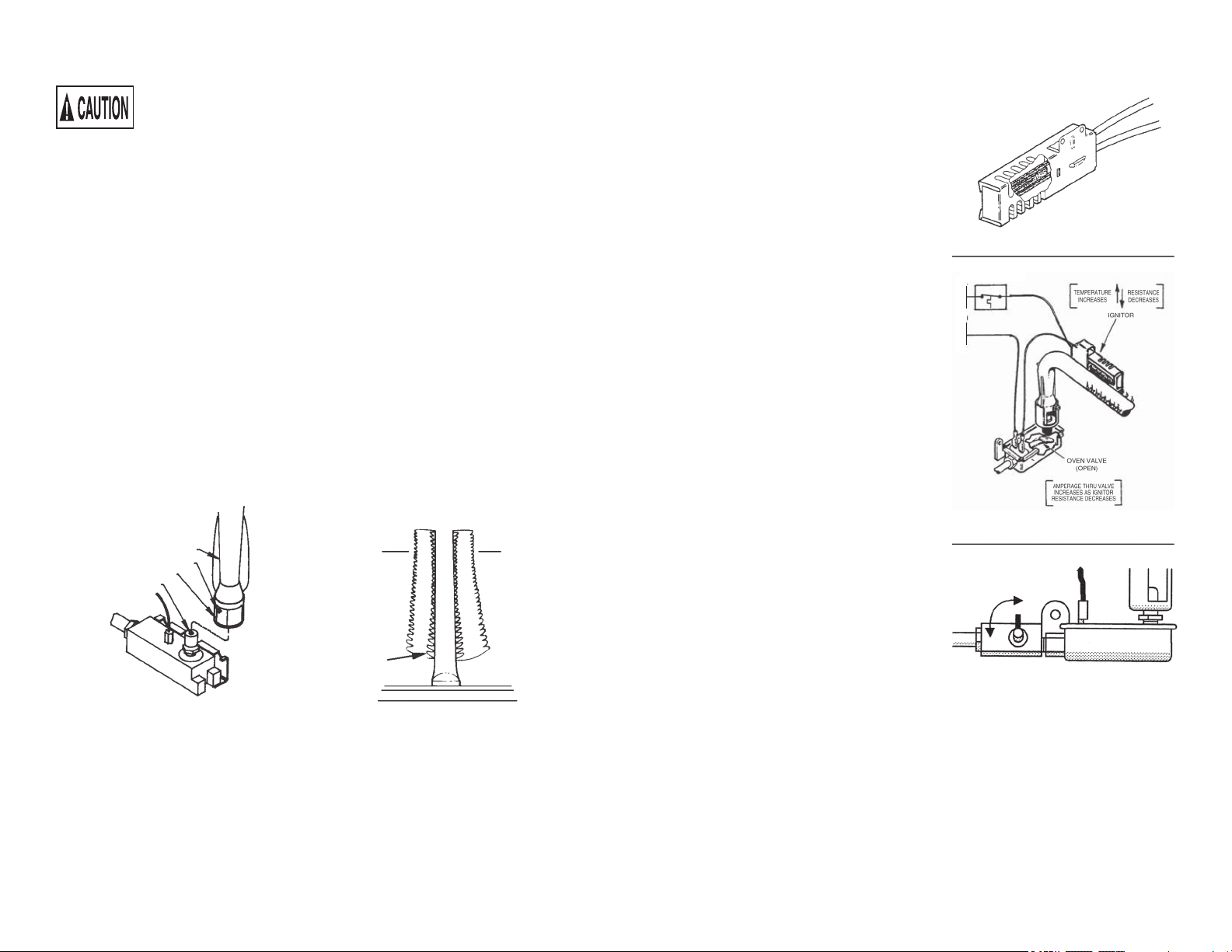

7. Automatic Oven Safety Valve

The orice hood on the oven safety valve regulates the ow of gas to the oven burner.

This valve adjusts in the same manner as the top burner valves and is located at the base

of the oven burner in the broiler compartment of the range. To gain access, simply

remove the broiler section. When set for LP, the orice hood is screwed snugly on the

valve. To adjust for use on Natural Gas, unscrew the orice hood until the proper ow

of gas is obtained.

8. Oven Burner Air Shutter Adjustment

The oven burner ame should be a clean, blue ame with distinct inner cones

approximately 1/2 inch long. A soft, lazy ame with indistinct comes means too much

gas or not enough air. A noisy lifting ame means too much air. If adjustments are

necessary you must rst loosen the lock screw located at the top of the air shutter, then

rotate the air shutter to the correct setting, and retighten screw.

Oven burner ame can be checked as follows (without burner bafe in place):

• To correct a yellow ame-Increase size of air shutter opening.

• To correct a lifting, but distinct, blue ame-Decrease size of air shutter opening.

The air shutter should be set approximately 2/3 open for natural gas, and approximately

full open on LP gas.

The oven burner air shutter adjustment is the same on ranges with a gas pilot or electric

ignition.

OVEN SAFETY VALVE

OVEN BURNER

OVEN BURNER

LOCK SCREW

AIR SHUTTER

ORIFICE

1/2" CONE

21

System Operation

The glow-bar ignition system consists of three

main components:

1. The thermostat (or range control).

2. The glow-bar ignitor.

3. The oven gas valve (also called the safety

valve).

The thermostat, ignitor and gas valve are wired

in series.

When the thermostat knob is turned to a

selected setting, this closes a set of electrical

contacts in the thermostat applying power to the

series circuit.

With power applied, the ignitor begins to heat.

The electrical resistance of the ignitor will

decrease as the surface temperature of the

ignitor increases.

Current owing in the circuit increases in

proportion to the drop in ignitor resistance.

The NORTON ignitor limits the operating

current ow in the circuit to 3.3 to 3.6 amps.

When the current has risen high enough to open

the valve, the surface temperature of the ignitor

is between 1800 to 2500 degrees F.

As gas ows out of the valve and into the

burner a portion of the gas ows across the hot

igniter and ignition occurs.

The ignitor will remain energized when the

burner is lit. Once the oven reaches the selected

temperature, the thermostat contacts will open

and remove power from the ignitor/valve

circuit. The valve will then close after a few

seconds and the burner ame will go out.

ALIGNMENTS AND ADJUSTMENT, Continued

Oven with Pilotless Electric Ignition: Glow Bar Ignition System (-7 Models)

Models with glow bar oven ignition have a manual shut-off valve located at the

safety valve in the rear of the broiler area. To access this valve, remove the broiler

pan and boiler rack. Turn the handle on the valve fully clockwise to close off gas.

If the ignitor glows and the oven won't come on, check this valve.

NORTON GLOWBAR

SERIES IGNITOR/VALVE CIRCUIT

SAFETY VALVE & SHUT-OFF

ON

OFF

L

N

THERMO STAT

"ON"