Loading ...

Loading ...

Loading ...

27

ELECTRICAL CONNECTION

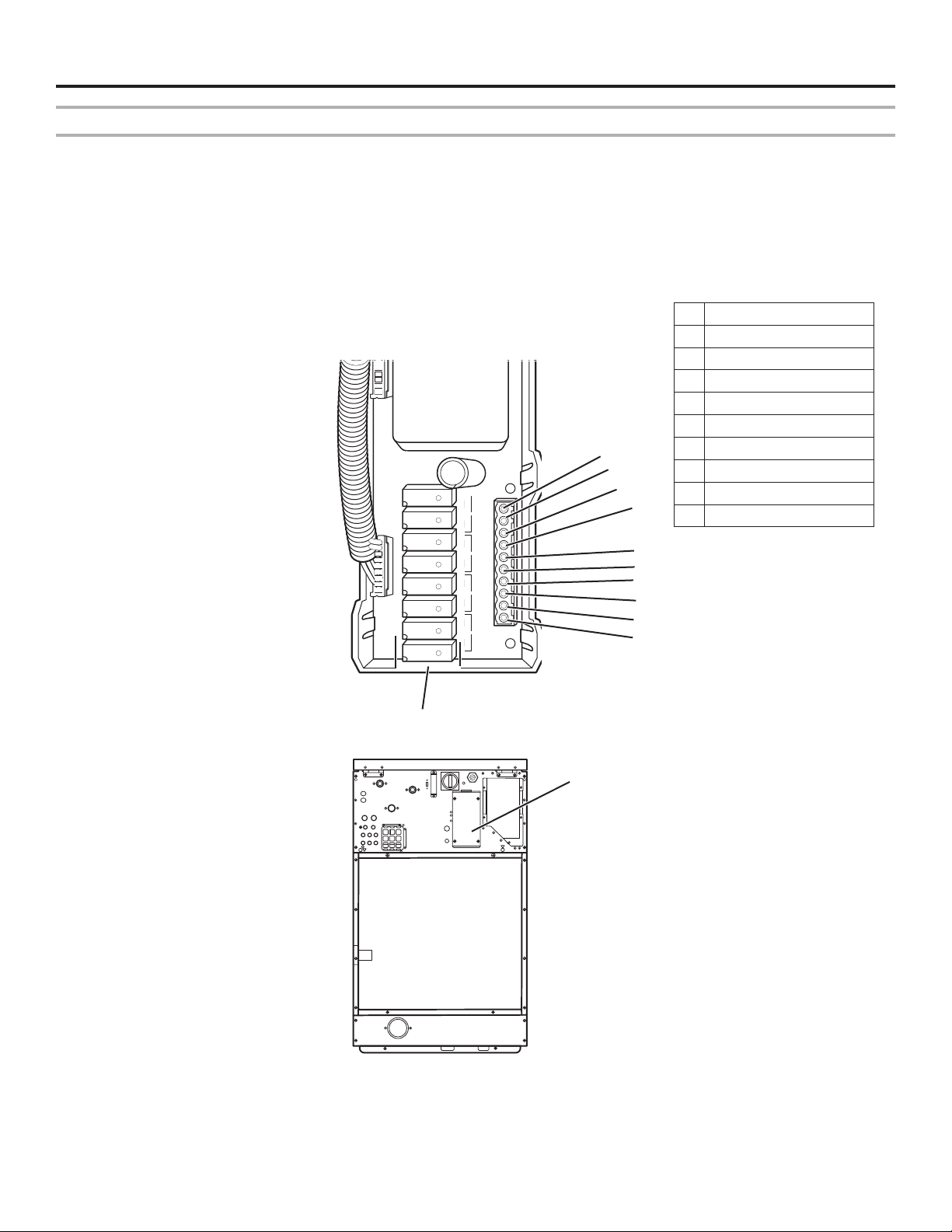

Electrical connection of the liquid soap supply system, if supplied (Optional on vended machines)

The power supplied to the liquid soap system must come from an external electric source. Do not connect the system in the washer.

All work must be performed by a qualied technician in compliance with all applicable local codes. Refer to the wiring diagram found

inside the washer attached to the side panel.

There is a labeled terminal block on the rear of the washer for control signal connections. There is a corresponding strip of LED lights

to show when each signal is active. Refer to the wiring diagram found inside the washer attached to the side panel. Supply pump

control signals are 24 VAC, maximum current is 10 mA. Wiring from the liquid soap system must be UL Recognized (AVLV2 and

AVLV8) and rated for 300 V minimum. Route all wires through the supplied plastic bushing, making sure to secure them with the cable

clamp. Afx the cover to the terminal block access before applying electric power to the washer. See the Programming Guide for

details on programming the liquid soap system.

C2

C

H

F1

F2

LED

Lights

External Liquid Soap

Connection Cover

1

2

10

9

8

5

7

3

4

6

1 Detergent signal

2 Bleach signal

3 Softener signal

4 Programmable signal 1

5 Programmable signal 2

6 Programmable signal 3

7 Programmable signal 4

8 Programmable signal 5

9 No output (do not use)

10 Neutral (common)

Loading ...

Loading ...

Loading ...