Loading ...

Loading ...

Loading ...

22

INSTALLATION OF THE RIGID WASHER-EXTRACTOR

WITHOUT PEDESTAL BASE

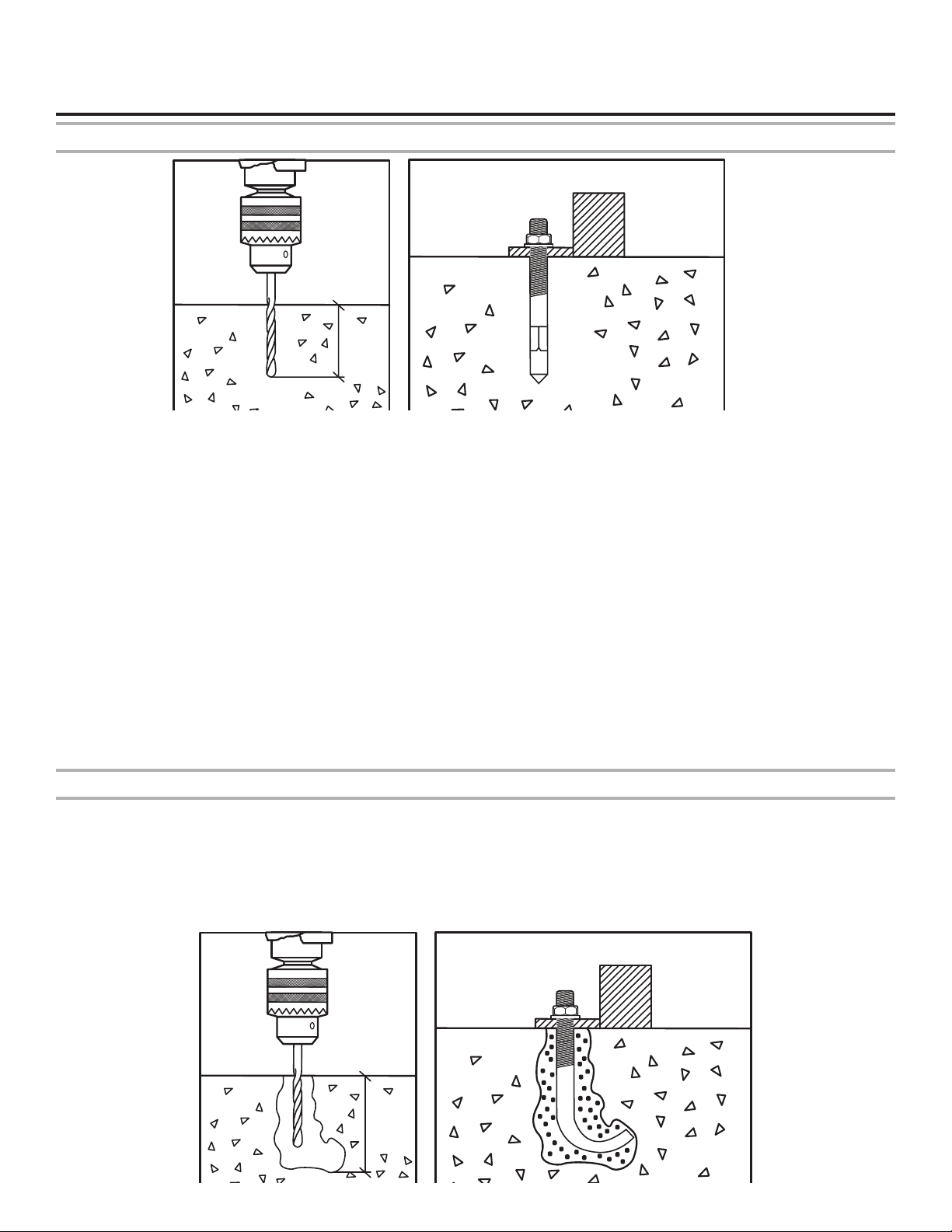

Using Expansion Bolts

Before anchoring the machine to the oor, make sure that its minimum resistance is equal or higher than 3500 psi (25 N/mm

2

).

First mark the locations of the mounting holes using the dimensions specied in the “Rigid Washing Machines” chart.

Next drill the mounting holes. Follow the manufacturing installation instructions, but the holes must be at least 4" (100 mm) deep.

The holes must not go all the way through the oor. Clean the holes with compressed air.

For the smoothest operation Whirlpool recommends that the washer be set with a precision, high strength, non-metallic, non-shrink

grout designed for precision grouting. Grout should have a minimum compressive strength of 10,000 PSI (69 MPa), when mixed to a

plastic consistency and fully cured.

a. If the washer is to be grouted in, it should be level and spaced between 3/8" (9 mm) and 1/2" (13 mm) off the oor to make room for

the grout.

b. Remove the washer leaving the spacers behind.

c. Mix the grout to a plastic consistency per the manufacturer's instructions.

d. Trowel the grout in to a depth slightly greater than the height of the spacers.

e. Reinstall the washer over the mounting fasteners. Use the fasteners to pull the washer down securely on the spacers. Do not fully

torque the fasteners.

f. Clean away any excess grout outside the washer as per the manufacturer's instructions.

g. Allow the grout to set for the minimum time recommended by the grout manufacturer for light use.

h. Tighten the bolts until the machine is securely fastened.

If not using grout, place the washer-extractor in position over the holes, then insert the expansion bolts in the holes. Be sure to use

5/8-11 (M16) expansion bolts, and that they protrude above the surface by 2" (50 mm). Once in place, tighten the bolts. Place the

washer-extractor in position above the bolts, and gradually tighten the nuts one after another to 195 Nm (144 ft lb).

Using J-bolts

Before anchoring the machine to the oor, make sure that its minimum resistance is equal or higher than 3500 psi (25 N/mm

2

).

First mark the locations of the mounting holes using the dimensions specied in the "Rigid Washing Machines" chart. Next make holes

to a depth, at minimum, equal to 4" (100 mm). Make the holes big enough to insert the J-bolt and clean using compressed air. Insert

the J-bolts in the holes and secure using a suitable anchoring compound, ensuring that the bolt protrudes above the surface by

2" (50 mm). Be sure to use 5/8-11 (M16) J-bolts.

Place the washer-extractor in position above the bolts, and gradually tighten the nuts one after another 195 Nm (144 ft lb).

Check the condition of the J-bolts one week after installation.

minimum

4 inch

100 mm

4 inch

minimum

100 mm

Loading ...

Loading ...

Loading ...