Loading ...

Loading ...

Loading ...

23

INSTALLATION INSTRUCTION

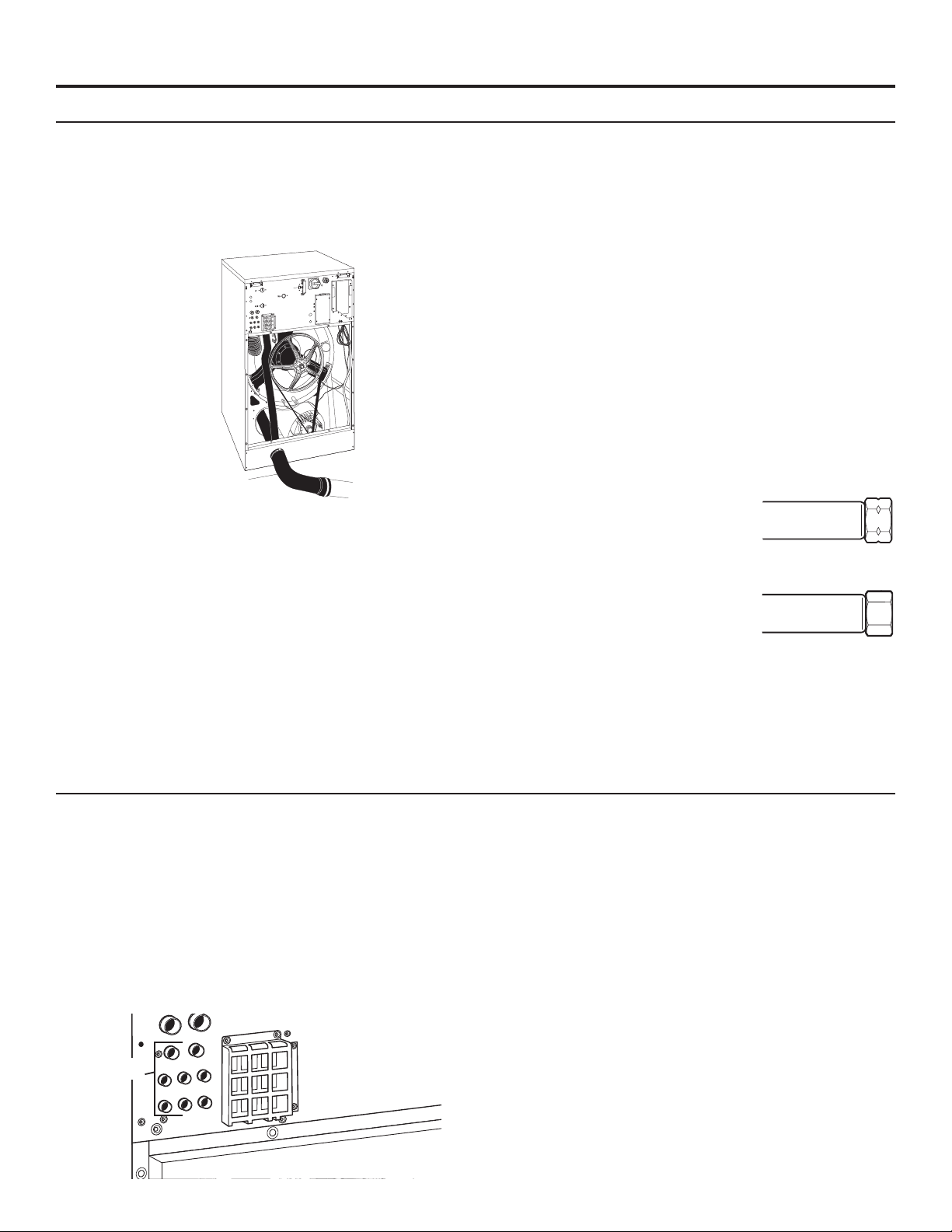

Connect the Drain Hose

1. The drain hose can be found shipped inside the drum

with the installation kit. The clamp for this hose is in the

installation kit. Attach the drain to the drain connection

located near the bottom of the rear of the washer. This is a

gravity-fed system, so you must install the drain hose with

the outlet lower than the drain connection to ensure proper

drainage. Do not kink the hose.

Drain Hose

2. The drain hose should end over, or in a floor drain or

drainage canal.

3. The drainage canal or drain pipe must be sized properly

to handle the total output of all washers connected to the

system. Each time a washer is added to the drain pipe,

the size of the pipe must increase to accommodate the

additional volume. The drain pipe at the first washer must

be 3" (76 mm) diameter. The pipe must increase to

4" (100 mm) diameter before the second washer and

5" (127 mm) diameter before the third washer.

4. For connecting the optional drain pump kit (Ordered

separately) refer to the instructions supplied with that kit.

Drain Connections

Use the provided drain hose to connect the washer’s drain pipe

to the facility drain or drain channel. Secure with the provided

clamp. The capacity of discharged water for each washer model

is 55.5 gal/min (210 L/min).

Water Hardness

Determine the water hardness level in water supply. Good wash

results are dependent on water hardness. In areas that have

medium and very hard water levels, a water softener may be

required.

Contact your water or soap distributor for determining the proper

soap and detergents to be used with your hardness levels for the

best wash results.

Water Supply Connections

Washers have 2 water inlets. For connection dimensions, see

“Dimensions and Technical Specications.”

1. Always use the exible hoses delivered with the washer. Do

not use a xed connection to the water supply.

2. Keep proper water pressure within range. See “Dimensions

and Technical Specifications.”

3. The water connection to the washer

requires a 3/4" British Standard Pipe

Thread fitting. The grooved end is a

U.S. thread. Threading an GHT

fitting or the GHT end of the

adapter hose will damage the

threads of the washer.

4. Flush water lines to remove debris.

Install the grooved side of the

adapter hoses to the hot and cold

side of the valves. Tighten fittings.

5. Attach non-grooved end of

adapter hoses to the washer. (On

55R, 55S, 65R, and 65S models,

there is a hose screen included in

the installation kit that needs to be placed here).

Tighten fittings.

6. Turn on water and check for leaks in the system.

External Supply Connections

All external liquid soap hose connections must be tight. Double

check that the clamps are tight after connections are made.

Make sure any unused open connections are sealed with an

appropriate cover.

The connections for the liquid soap are on the rear of the

washer and must be drilled open in order to use them. Only

drill out the connections that will be used. There are eight (8)

3/8" (9 mm) diameter connections; use a 5/16" (8 mm) diameter

drill bit to drill out these holes. There can only be eight (8)

pumps in the system. Be sure to clean out all the drill shavings

completely so they do not clog the inlets and hoses. Connect to

liquid soap pumps to the left openings rst. Set the ow rate of

the pumps between 16 and 26 gal/hr (60 and 100 l/hr).

IMPORTANT: The incoming water dilutes the liquid soap and

brings it into the tub assembly.

Check with your liquid soap provider to ensure that your

soap is inert to Polypropylene (PP) and Polyvinyl Chloride (PVC)

materials.

Make sure the hoses and wiring for the liquid soap pumps are

not damaged, pinched, rubbed or damage to the machine could

occur.

The liquid soap pumps used must be capable of providing the

requested quantity in less than 30 seconds.

3/4" Garden

Hose (GHT) tting

3/4" British Standard

Pipe Thread (BSPP)

tting

Liquid Soap

Connections

Loading ...

Loading ...

Loading ...