Loading ...

Loading ...

Loading ...

Piping

Liebert

®

SRC

™

66launaM resU

5.5 Air Purging

Air purging is performed after all piping is connected between the indoor and the outdoor unit. This step is

necessary to be sure that air refrigerant can flow through the system without the danger of leakage or

pressure issues. Air and moisture that is left in the ping can lead to undesirable results and can cause

damage to the working unit. it is important to go through a complete air-purging cycle to be sure that the

lines are cleared out. Note that you may have to repeat this process if any air or moisture is found to

remain in the piping. After air purging and evacuating the lines, be sure do a leak test for all piping and

tubing.

1. Verify that each set of pipes (liquid and gas) are properly connected between the indoor and outdoor

unit.

2. Verify that all wiring for a test run is complete.

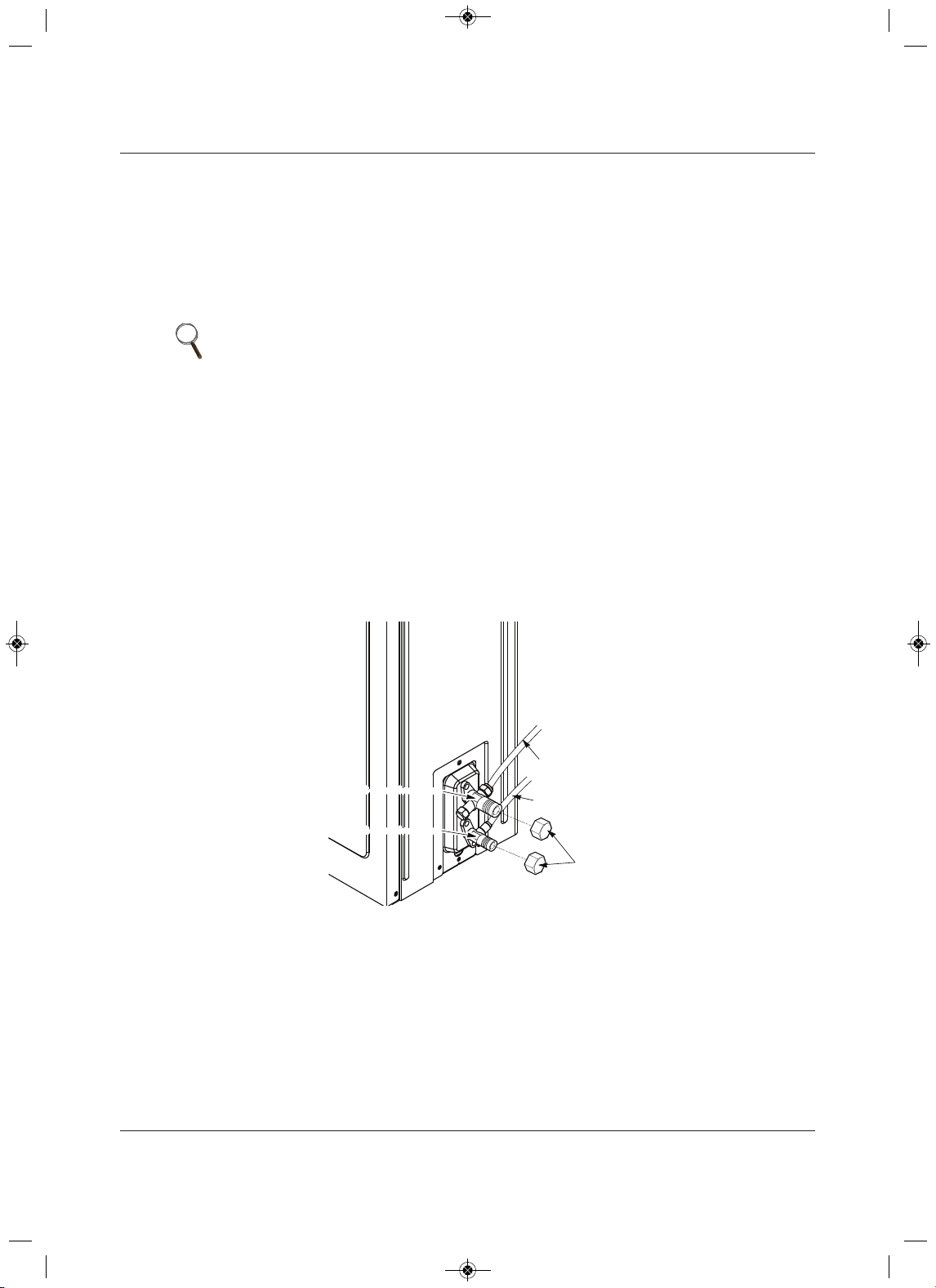

3. Remove the service-valve caps from the gas and liquid valves at the outdoor unit, Figure 5-39.

• Keep both liquid and gas service valves closed at this step.

Figure 5-39 Removing service-valve caps from outdoor unit for purging

NOTE

Insufficient or incorrectly-performed air purging may lead to the following:

• Pressure in the system can rise.

• Operating current can rise.

• Cooling or heating efficiency falls.

• Moisture in the refrigerant circuit may freeze and block capillary tubing.

• Water can lead to corrosion of parts in the system.

Evacuation

Outdoor Unit

Gas side

Liquid side

Valve

Caps

2-way valve(Close)

3-way valve(Close)

2-way valve(Close)

3-way valve(Close)

MFL67502030 17. 7. 13. 오오 3:05 Page 76

Loading ...

Loading ...

Loading ...