Loading ...

Loading ...

Loading ...

Piping

63 Liebert

®

SRC™ User Manual

5.4 Piping Insulation

To prevent heat loss/heat gain through the refrigerant piping, all refrigerant piping, including liquid lines and

vapor lines, must be insulated separately. Insulation must be a minimum 1/2-in. thick, and the thickness

may need to be increased based on ambient conditions

and local codes. All refrigerant piping, including

field-supplied isolation ball valves, service valves, and elbows must be completely insulated using closed-

cell pipe insulation. All insulation join ts must be glued with no air gaps. Insul

ation material must fit snugly

against the refrigerations pipe with now space between it and the pipe. Insulation passing through pipe

hangers, inside conduit, and/or sleeves must not be compressed. Protect insulation inside hangers and

supports with a second layer. All pipe insulation exposed

to direct sunlight and deterioration-producing

elements must be properly protected with a PVC-aluminum vapor-barrier jacket, or placed in a weather-

resistant enclosure such as a pipe rack with a top cover. The design engineer should perform calculations

to determine if the factory-supplied insulation jackets have sufficient thickness to meet local codes and to

void sweating at job-site conditions. Maximum refrigerant-pipe temperature is 227°F. Minimum refrigerant-

pipe temperature is –4°F. Add additional insulation if necessary.

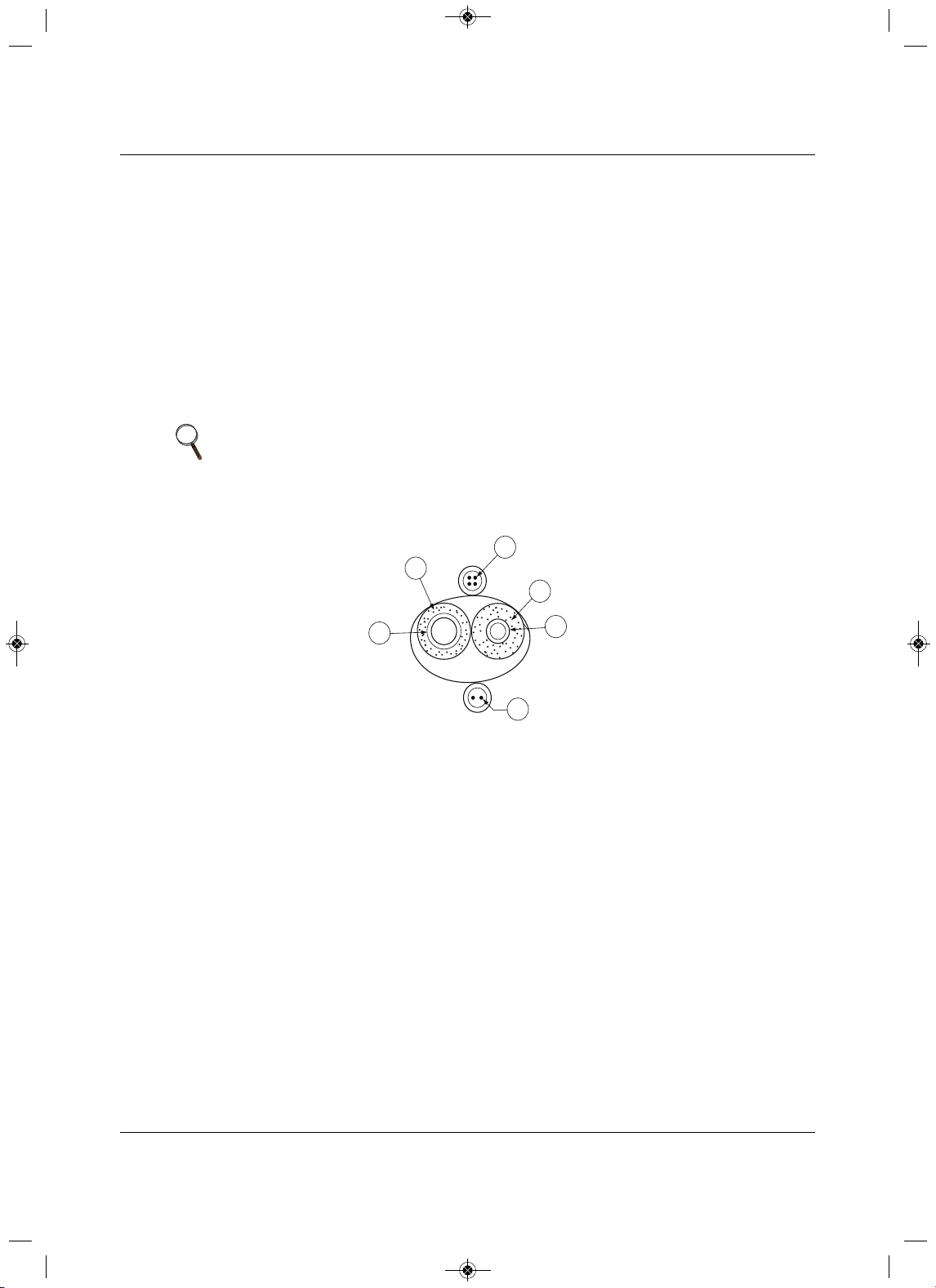

Figure 5-3

6 Typical pipe-ins u lation, power wire, and communications-cable arrangement

NOTE

• Do not insulate gas and liquid pipes together as this can result in pipe

leakage and malfunction due to extreme temperature fluctuations.

• Be sure to fully insulate the piping connections.

Liquid Pipe

Communication Cables

Gas Pipe

Power Wiring

Insulation

A

B

C

D

E

E

D

D

B

A

C

MFL67502030 17. 7. 13. 오오 3:05 Page 73

Loading ...

Loading ...

Loading ...