Loading ...

Loading ...

Loading ...

Piping

41 Liebert

®

SRC™ User Manual

5.2.4 No Pipe Size Substitutions

Use only the pipe size recommended by this manual. Using a different size is prohibited and may result in

a system malfunction or failure to work at all.

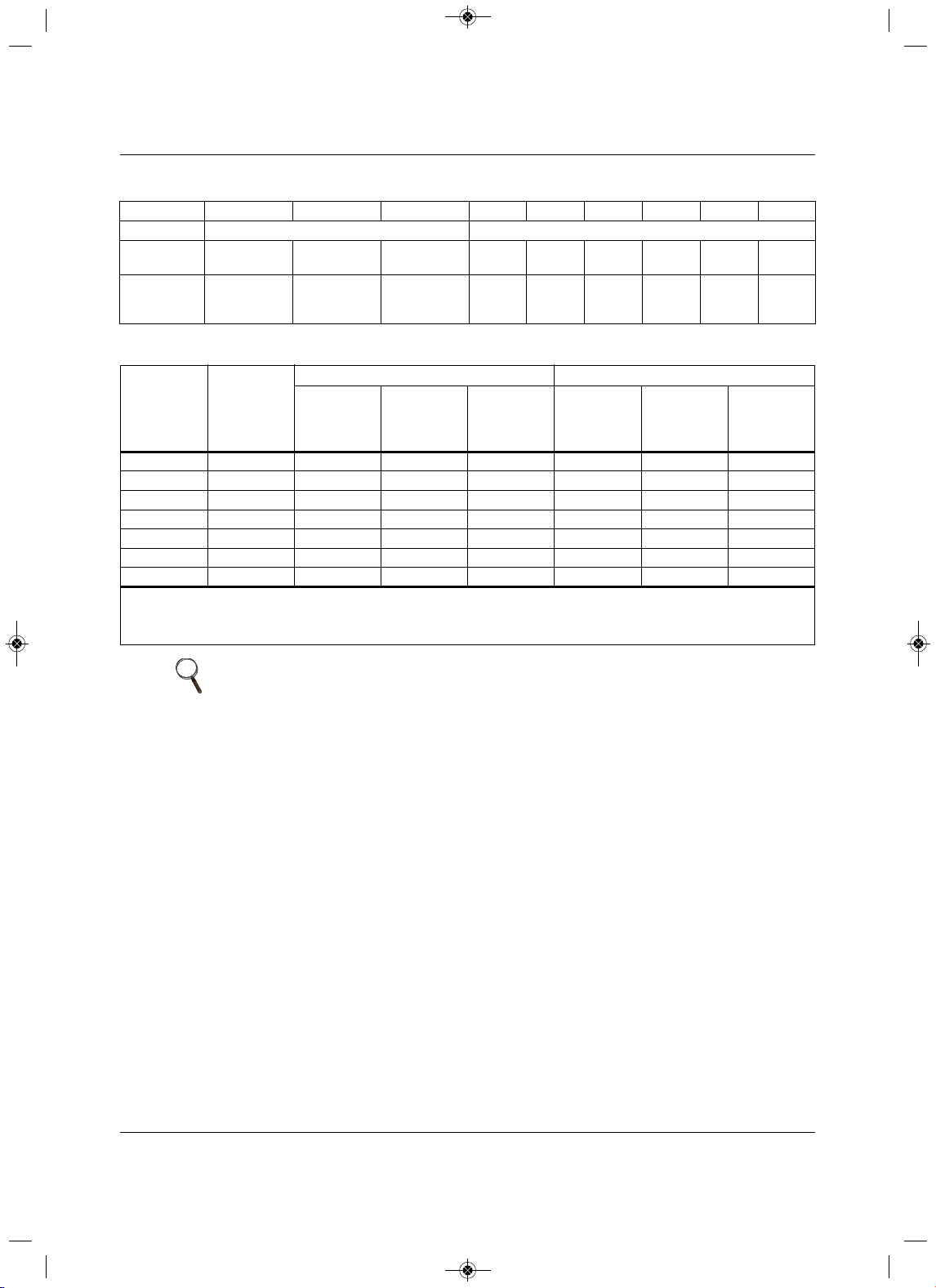

Table 5-5 Piping-tube thickness

OD (in.) 1/4 3/81/25/83/4 7/81-1/81-3/81-5/8

Material Rigid type “K” or “L” and a soft ACR acceptable Rigid type “K” or “L” only

Min. Bend

Radius (in.)

.563 .9375 1.52.25 3.03.03.5 4.0

4.5

Min. Wall

Thickness

(in.)

.03 .03 .035 .040 .042 .045 .050 .050 .050

Table 5-6 ACR copper-tubing dimensions and physical characteristics

1-4

Nominal

Pipe Outside

Diameter

(in.)

Actual

Outside

Diameter

(in.)

Drawn Temper Annealed Temper

Nominal

Wall

Thickness

(in.) Weight (lb/ft)

Cubic ft per

Linear ft

Nominal

Wall

Thickness

(in.) Weight (lb/ft)

Cubic

ft per

Linear ft

1/4 0.250 ———0.030 0.081 .00020

3/80.375 0.030 0.126 .00054 0.032 0.134.00053

1/20.500 0.035 0.198 .00101 0.032 0.182 .00103

5/80.625 0.0400.285 .00162 0.035 0.251 .00168

3/4 0.750 0.0420.362 .002420.0420.362 .

00242

7/80.875 0.0450.455 .00336 0.0450.455 .00336

1-1/81.125 0.050 0.655 .00573 0.050 0.655 .00573

1. All dimensions provided are in accordance with ASTM B280 – Standard.

2. Design pressure = 551 psig.

3. ACR tubing is available as hard-drawn or annealed (soft) and are suitable for use with R410A refrigerant.

4. The Copper Tube Handbook, 2010, Copper Deve

lopment Association Inc., 260 Madison Avenue, New York, NY 10016.

NOTE

• Commercially-available piping often contains dust and other materials.

Always blow it clean with a dry, inert gas.

• Prevent dust, water or other contaminants from entering the piping during

installation. Contaminants can cause mechanical failure.

MFL67502030 17. 7. 13. 오오 3:05 Page 51

Loading ...

Loading ...

Loading ...