Loading ...

Loading ...

Loading ...

Piping

Liebert

®

SRC

™

User Manual 38

5.1.3 Loosening Flare Nuts

Always use 2 wrenches to loosen the flare nuts.

5.2 Piping Materials and Handling

Pipes used for the refrigerant piping system must include the specified thickness, and the interior must be

clean.

While handling and storing, do not bend or damage the pipes, and take care not to contaminate the interior

with dust, moisture, etc. See Table 5

-3 for care of piping.

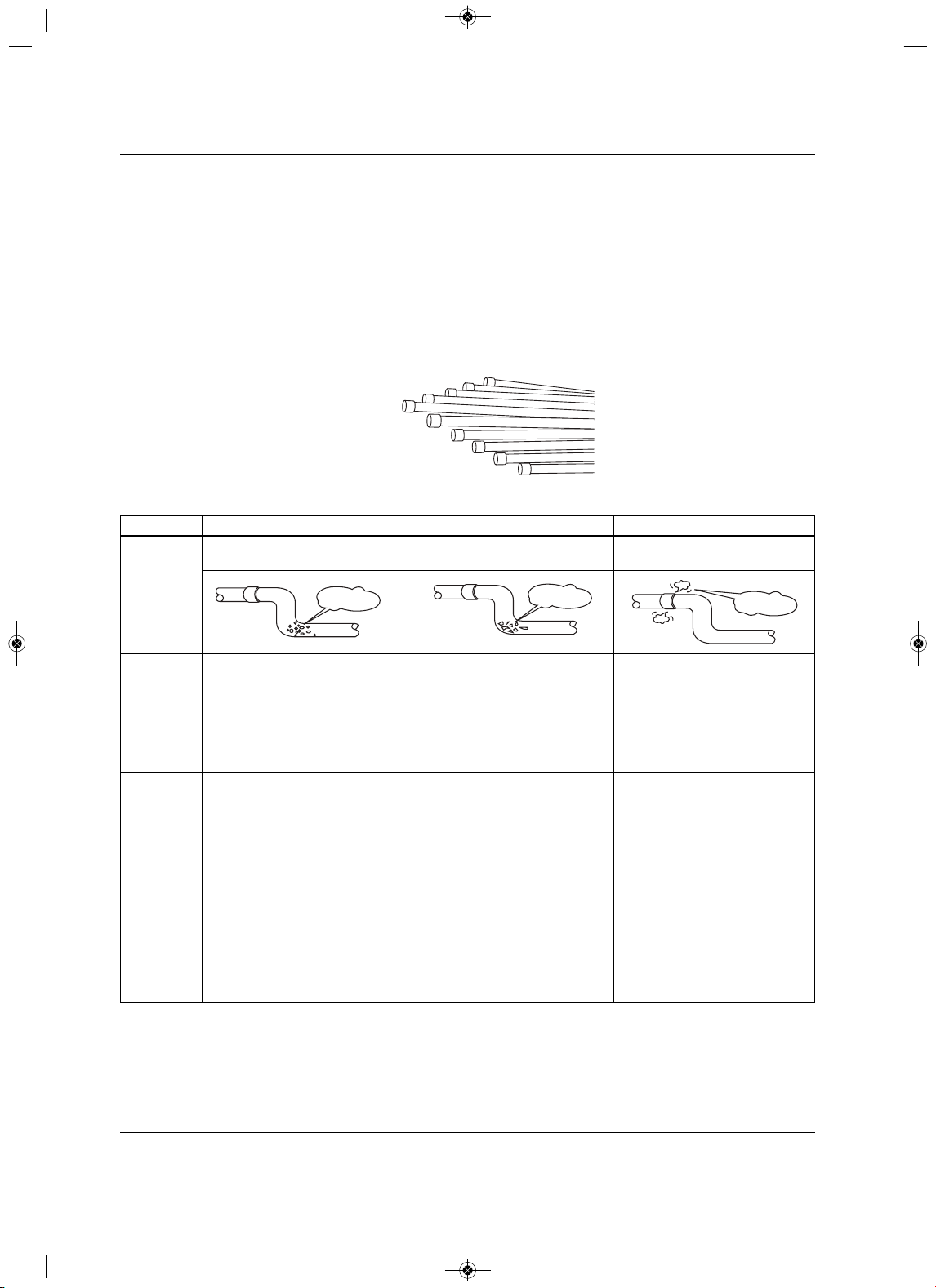

Figure 5-4 Keep piping capped while storing

Table 5-3Three principles of refrigerant piping

DryClean Airtight

Principles No moisture should be inside the

piping.

No dust should be inside the

piping.

No leaks should occur.

Problems

Caused

• Significant hydrolysis of refrigerant

oil.

• Refrigerant oil degradation.

• Poor insulation of the

compressor.

•System does not operate properly.

•EEVs, capillary tubes are clogged.

• Refrigerant oil degradation.

•Poor insulation of the

compressor.

•System does not operate

properly.

•EEVs and capillary tubes

become clogged.

• Refrigerant gas leaks/shortages.

• Refrigerant oil degradation.

•Poor

insulation of the

compressor.

•System does not operate

properly.

Solutions • Remove moisture from the piping.

• Piping ends should remain capped

until connections are complete.

• Do not install piping on a rainy day.

• Connect piping properly at the

unit’s side.

• Remove

caps only after the piping

is cut, the burrs are removed, and

after passing the piping through

the walls.

•Evacuate system to a minimum of

500 microns and ensure the

vacuum holds at that level for 24

hours.

• Remove dust from the piping

.

•Piping ends should remain

capped until connections are

complete.

• Connect piping properly at the

side of the unit.

• Remove caps only after the

piping is cut and burrs are

removed.

• Retain the cap on the piping

when passing it through walls,

etc.

• Test system for air-tightness.

• Perform brazing proc3edures

that comply with all applicable

standards.

• Perform flaring procedures that

comply with all applicable

standards.

• Perform flanging procedures that

comply with all applicable

standards.

•Ensure that refrigerant lines are

pressure-test to

550 psig.

-

Moisture

Dust

Leaks

MFL67502030 17. 7. 13. 오오 3:05 Page 48

Loading ...

Loading ...

Loading ...