Loading ...

Loading ...

Loading ...

7

ENGLISH

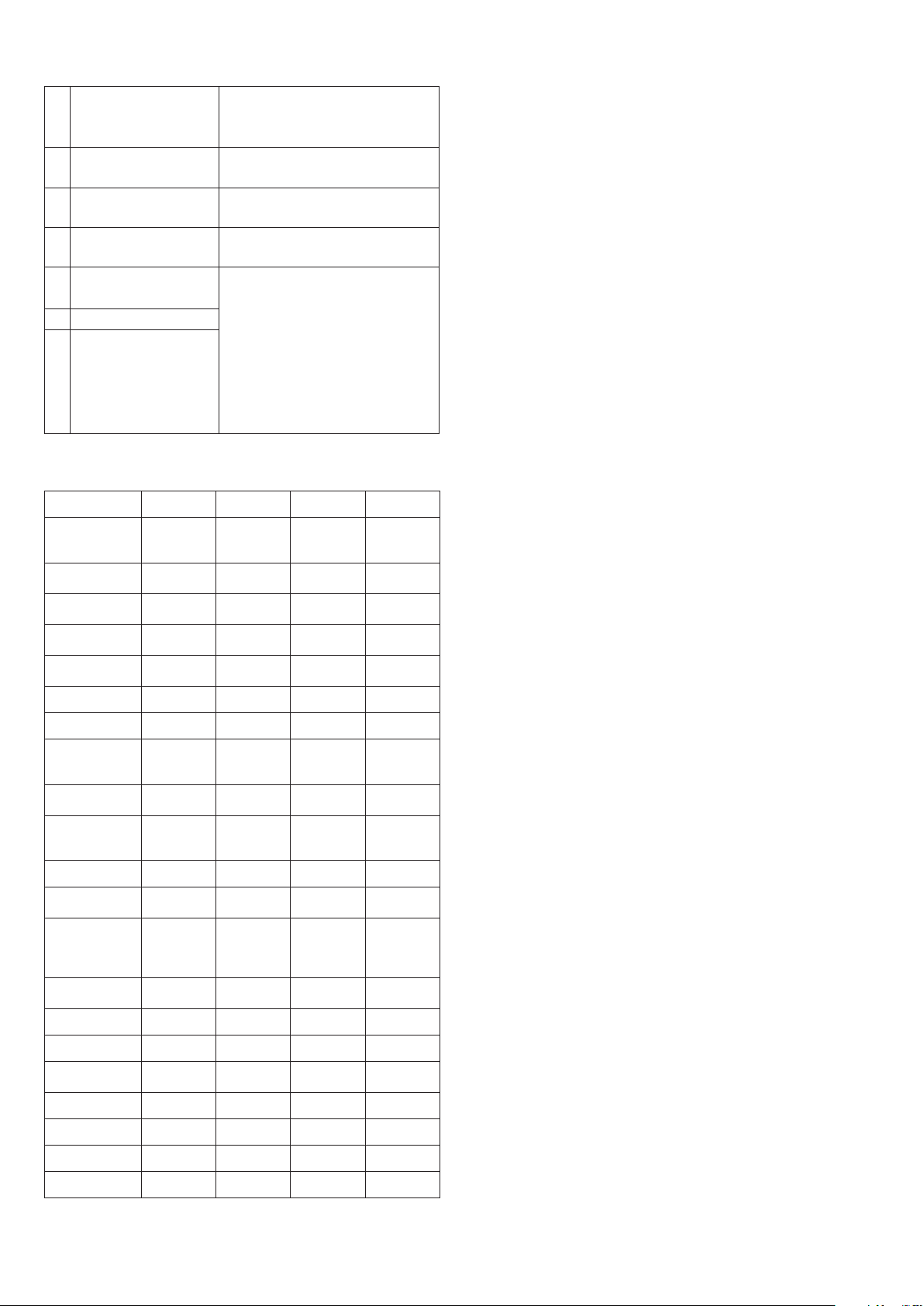

MALFUNCTION ANALYSIS

Malfunction code

H8 Tank is full of water. 1. Pour out the water inside tank.

2. If “H8” still exists, please contact

professional person to maintain

the unit.

F1 Malfunction of ambient

temperature sensor.

Please contact professional person

to deal with it.

F2 Malfunction of evapora-

tor temperature sensor.

Please contact professional person

to deal with it.

F0 1. Refrigerant is leaking.

2. System is blocked.

Please contact professional person

to deal with it.

H3 Overload protection for

compressor.

1. If ambient temperature is too

high, power off the unit and then

energize it for operation after the

ambient temperature drops to be-

low 35°.

2. Check if the evaporator and con-

denser are blocked by some ob-

jects. If yes, take away the ob-

jects, power off the unit and then

energize it for operation.

3. If the malfunction still occur,

please contact our after-sales ser-

vice center.

E8 Overload malfunction.

F4 Outdoor tube

temperature

sensor is open/

short-circuited.

11. SPECIFICATIONS

MODELTAD-220ETAD-226ETAD-229ETAD-235E

POWER SOURCE

Single Phase

220~240 V,

50 Hz

Single Phase

220~240 V,

50 Hz

Single Phase

220~240 V,

50 Hz

Single Phase

220~240 V,

50 Hz

COOLING

CAPACITY

2,1 kW

(7.165 BTU)

2,6 kW

(8.870 BTU)

2,9 kW

(9.894,8 BTU)

3,5 kW

(11.942 BTU)

COOLING POWER

INPUT

805 W1.000 W935 W1.345 W

HEATING

CAPACITY

– – –

3,3 kW

(11.260 BTU)

HEATING POWER

INPUT

– – – 1.175 W

EE Class / EER*A / 2,60A / 2,60A+ / 3,10A / 2,60

EE Class / COP*– – – A+ / 2,80

POWER

CONSUMPTION IN

STANDBY MODE

0,5 W0,5 W0,5 W0,5 W

DEHUMIDIFYING

CAPACITY

1,0 L/h1,43 L/h1,60 L/h1,80 L/h

OPERATING

CURRENT

3,5 A 4,4 A4,1 A

5,8 A / 5,1 A

(Cooling/

Heating)

AIR FLOW (MAX.)320 m

3

/h320 m

3

/h360 m

3

/h360 m

3

/h

FOR ROOMS UP

TO

10 - 16 m

2

10 - 16 m

2

15 - 22 m

2

15 - 22 m

2

OPERATING

TEMP. RANGE

16~35°C16~35°C16~35°C

16°C~35°C /

10°C~ 27°C

(Cooling /

Heating)

SOUND POWER

LEVEL

63 dB 64 dB64 dB65 dB

UNIT PROTECTIONIPX0IPX0IPX0IPX0

FUSE RATING3,15 A 3,15 A 3,15 A 3,15 A

DIMENTIONS

(W×H×D)

315×770×

395 mm

315×770×

395 mm

390×820×

405 mm

390×820×

405 mm

WEIGHT24,5 kg27,0 kg36,0 kg36,5 kg

COMPRESSORROTARYROTARYROTARYROTARY

REFRIGERANT

R290 / 0,16 kgR290 / 0,22 kgR290 / 0,30 kgR290 / 0,30 kg

GWP3 3 3 3

*Confirm to EN-14511: 2018

NOTE: Cooling air capacity will vary according to temperature and

humidity of the room.

(For TAD-229E)

Frequency band(s) in which the radio equipment operates:

2400MHz-2483.5MHz

Maximum radio-frequency power transmitted in the frequency

band(s) in which the radio equipment operates: 20dBm

12. VENTING KIT ACCESSORIES

If the unit is to be used exclusively in one space, the cooling efficien-

cy will be enhanced by using the following venting kit accessories.

USING EXHAUST DUCT SET (Fig. H)

1. Prepare the below accessory.

H1 Exhaust duct hose adapter nozzle (Fix to unit)

H2 Exhaust duct hose

H3 Exhaust nozzle (upper) + Exhaust nozzle (lower)

2. To fix the Exhaust nozzle (upper) and the Exhaust nozzle (low-

er) together, press the clasp forcibly into the groove. (Fig. H4)

3. Insert one end of exhaust duct hose (flexible tube) (H2) into

exhaust duct hose adapter nozzle (H1) by turning it counter

clockwise. And install exhaust nozzle (upper + lower) (H3) into

another side of exhaust duct hose. (Fig. H5)

4. Face the side with “TOP” upwards. Insert exhaust duct hose

adapter nozzle into the groove of exhaust outlet until you hear

a sound. (Fig. H6)

5. Place the exhaust hose outdoors. (Fig. H7)

NOTE: Place the unit as close as possible to the window or

door. (H5, H6, H7)

13. Specialist’s Manual

Aptitude requirement for maintenance man(repairs should be do-

ne only be specialists).

a. All the work men who are engaging in the refrigeration system

should bear the valid certification awarded by the authoritative

organization and the qualification for dealing with the refrigera-

tion system recognized by this industry.

b. It can only be repaired by the method suggested by the equip-

ment’s manufacturer.

If it needs other technician to maintain and repair the appliance,

they should be supervised by the person who bears the qualifi-

cation for using the flammable refrigerant.

Safety preparation work before installation

The safety must be inspected before maintaining the appliances

with the flammable refrigerant for reducing the flammable hazard

to the lowest.

Work shall be undertaken under a controlled procedure so as to

minimise the risk of a flammable gas or vapour being present while

the work is being performed.

Detection of flammable refrigerants

Under no circumstances shall potential sources of ignition be used

in the searching for or detection of refrigerant leaks. A halide torch

(or any other detector using a naked flame) shall not be used.

Environment checking

• All maintenance staff and others working in the local area shall

be instructed on the nature of work being carried out. Work in

confined spaces shall be avoided. The area around the work-

space shall be sectioned off. Ensure that the conditions within

the area have been made safe by control of flammable material.

• The area shall be checked with an appropriate refrigerant detec-

tor prior to and during work, to ensure the technician is aware of

potentially toxic or flammable atmospheres.

Ensure that the leak detection equipment being used is suitable

for use with all applicable refrigerants, i.e. non-sparking, ade-

quately sealed or intrinsically safe.

• No person carrying out work in relation to a refrigeration system

which involves exposing any pipe work shall use any sources of

ignition in such a manner that it may lead to the risk of fire or

explosion. All possible ignition sources, including cigarette

smoking, should be kept sufficiently far away from the site of in-

stallation, repairing, removing and disposal, during which refrig-

erant can possibly be released to the surrounding space.

Prior to work taking place, the area around the equipment is to

be surveyed to make sure that there are no flammable hazards

or ignition risks. “No Smoking” signs shall be displayed.

• If any hot work is to be conducted on the refrigeration equip-

ment or any associated parts, appropriate fire extinguishing

equipment shall be available to hand. Have a dry powder or CO

2

fire extinguisher adjacent to the charging area.

Loading ...

Loading ...

Loading ...