Loading ...

Loading ...

Loading ...

7

APPLIANCE SERVICING

IMPORTANT!

ALL SERVICING AND MAINTENANCE ARE TO BE COMPLETED BY THE MANUFACTURER’S

AUTHORISED PERSONNEL ONLY.

Before carrying any servicing operation disconnect the appliance from gas and electric supply and extra

appliance from final installation place in order to have access to the appliance for proper servicing

intervention.

STEP 1: PRESSURE REGULATOR.

For NG or ULPG installation ref. to fig. 7 and chapter ‘Appliance gas connection’ 7

STEP 2: SURFACE BURNERS

For surface burners conversion ref to table 1 chapter ‘Adaption to various types

of gas’ and chapter ‘Conversion to different types of gas’

STEP 3: VISUAL CHECKS

The following visual check must be performed to ensure that the conversion has

been carried out properly and without damage to other components of the range.

Verify that the flame of the oven burner be completely blue and with regular aspect

as shown below.

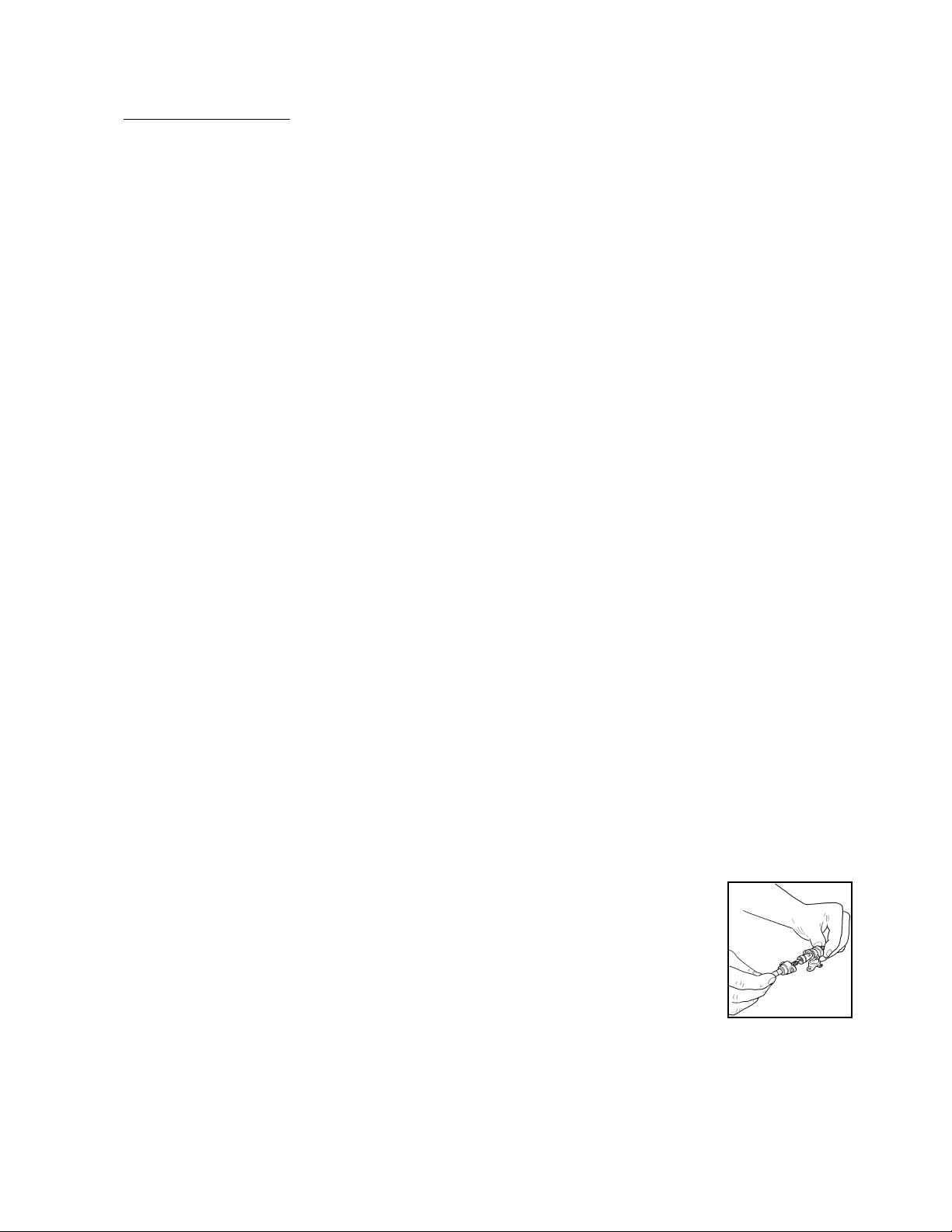

CONNECTION OF THERMOCOUPLE TO THERMOSTAT

The thermocouple for oven burner is connected to the magnet. Tight gently the connection.

The tip of the spark plug or thermocouple must fully overlap at least the first gas emission hole of the burner.

After performing all these visual checks, reinstall the bottom panel of the oven compartment and proceed

to setting the minimum for each burner.

STEP 4: MINIMUM FLAME ADJUSTMENT

WARNING!

These adjustments should be made only for use of the appliance with Natural gas.

For use with ULPG, the bypass screw must be fully turned in a clockwise direction.

Surface burners

Light one burner at a time and set the knob to the MINIMUM position (small

flame). Remove the knob.

The range is equipped with a safety valve. Using a small-size slotted screwdriver,

locate the choke valve on the valve body and turn the choke screw to the right or

left until the burner flame is adjusted to desired minimum.

Make sure that the flame does not go out when switching quickly from the

MAXIMUM to the MINIMUM position.

Greasing the valves

If it becomes difficult to operate the valve, it should be greased immediately by

following the instructions listed below:

1) Disassemble the valve body by loosening the two screws located on

the body of valve.

2) Extract and clean the seal cone and its housing with a cloth.

3) Lightly grease the cone with special grease.

4) Insert the cone, moving it several times, remove it again, remove the

excess grease and make sure that the gas passage ways are

unobstructed.

5) Replace all the pieces by reversing the order in which they were

disassembled and check that the valve operates correctly.

Room Ventilation

To ensure that the appliance operates correctly, the room where it is installed must

be continuously ventilated. The room volume should not be less than 25m3 and the

quantity of air should be based on the regular combustion of gas and on the

ventilation of the room. Natural air will flow through permanent openings in the

Loading ...

Loading ...

Loading ...