Loading ...

Loading ...

Loading ...

36

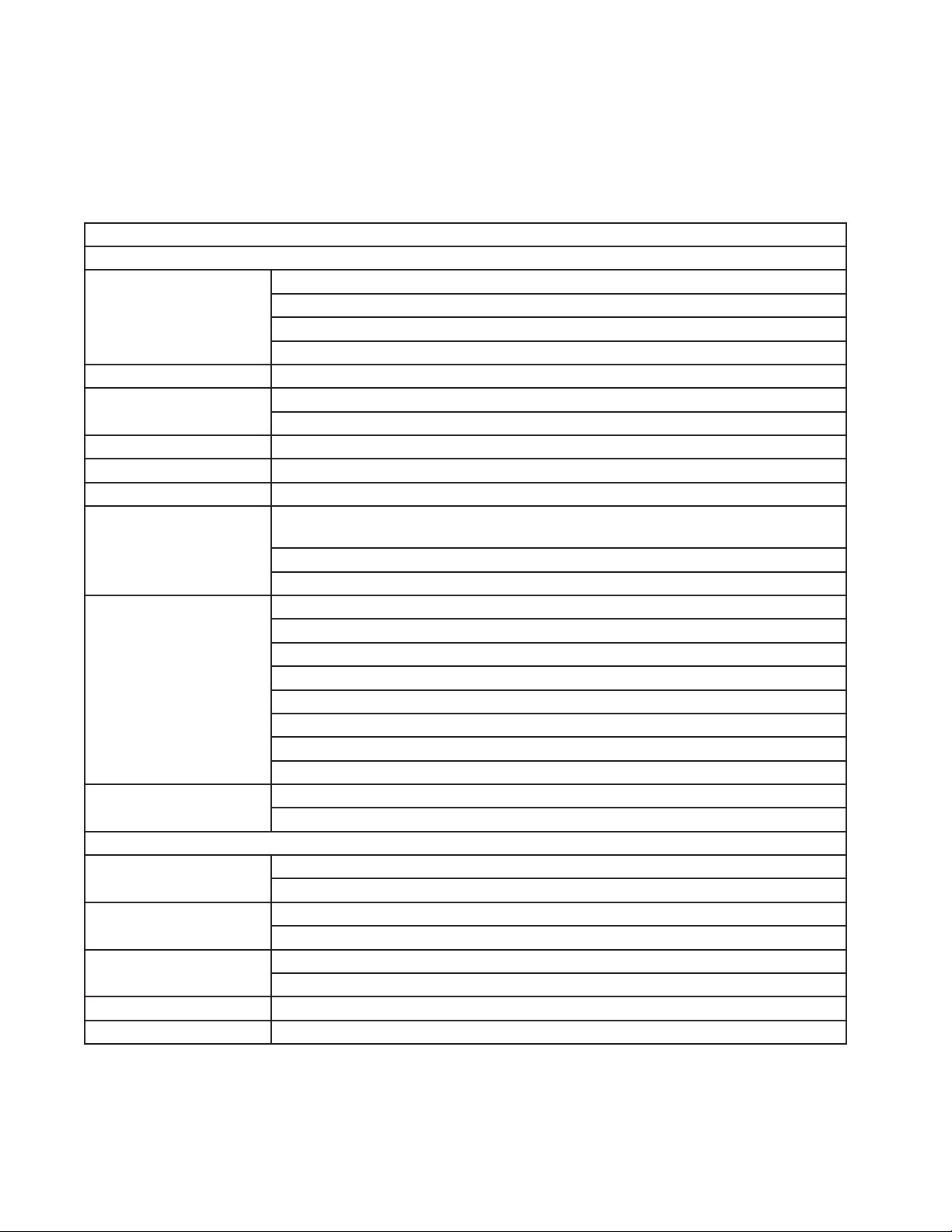

F. Diagnostic Tables

Before consulting the diagnostic charts, check for correct installation, proper voltage per

appliance nameplate, and adequate water supply. Check control board using the steps in

"II.C. Control Board Check."

1. No Ice Production

No Ice Production - Possible Cause

Startup

1. Power Supply a) Off, blown fuse, or tripped breaker.

b) Loose connection.

c) Bad contacts.

d) Not within specications.

2. Water Supply a) Water supply off or pressure too low.

3. Power Switch

(Control Box)

a) "OFF" position.

b) Bad contacts.

4. Control Transformer a) Coil winding opened.

5. Fuse (Control Box) a) Blown.

6. BC1 (Infrared Sensor) a) No power or defective.

7. BC(2) (Mechanical

Stand-Alone or

Backup)

a) Tripped with bin lled with ice.

(9-beep alarm when used in conjunction with BC1 (infrared sensor)

b) Switch stuck open.

c) Actuator paddle does not move freely.

8. High-Pressure Switch a) Bad Contacts.

b) Dirty air lter or condenser.

c) Ambient or condenser water temperature too warm.

d) Refrigerant overcharged.

e) Fan not operating (except water-cooled model).

f) Refrigerant line or component restricted.

g) Condenser water pressure too low or off (water-cooled model).

h) Water regulating valve set too high (water-cooled model).

9. Control Switch a) "DRAIN" position. 2-beep alarm if in "DRAIN" position for more than 15 min.

b) Bad contacts.

Fill Cycle

1. Control Board a) No Power to inlet water valve.

b) No power to oat switch or not reading oat switch condition.

2. Inlet Water Valve a) Screen or orice clogged.

b) Coil winding opened.

3. Float Switch a) Float does not move freely.

b) Defective.

4. Drain Water Valve a) Valve seat clogged and water leaking.

5. Hoses a) Disconnected.

Loading ...

Loading ...

Loading ...