Loading ...

Loading ...

Loading ...

● Ret the front hood.

Check that the hood opens completely, without interfering

with the lifting system; this could occur in certain cases and

requires the creation of an outlet in the lower left region of

the hood.

To eliminate interference in hoods which have already been

prearranged, simply use the tracing inside the hood itself;

on the contrary, follow the indications provided in the draw-

ing.

27

35

12

53148

Use a suitable tool to perform this operation, making sure all

cutting burr is removed and any sharp edges are smoothed o

to prevent cuts in cases of accidental contact.

● Reconnect the headlamp connector and reinstate the elec-

tric cable fastener clamp.

● Reassemble the left and right side guards.

● Apply the attachment to the interface, check that it

rises and lowers correctly and that the lock system

works properly in a raised position.

3. PRE-ASSEMBLY OF THE PTO ON THE LIFTING

MODULE

NOTE - The descriptions that follow presume that the PTO

components have been tted on the lifting module on the

work bench, before the latter is applied to the machine.

If the lifting module is already assembled on the machine,

it is recommended to remove it following the instructions

provided in Chap. 2 in reverse order.

NOTE - The required ttings are contained in the bags

marked with a letter. ( «E» - «F» - «G» - «H» - «N»)

Tool Bag «E» - «N»

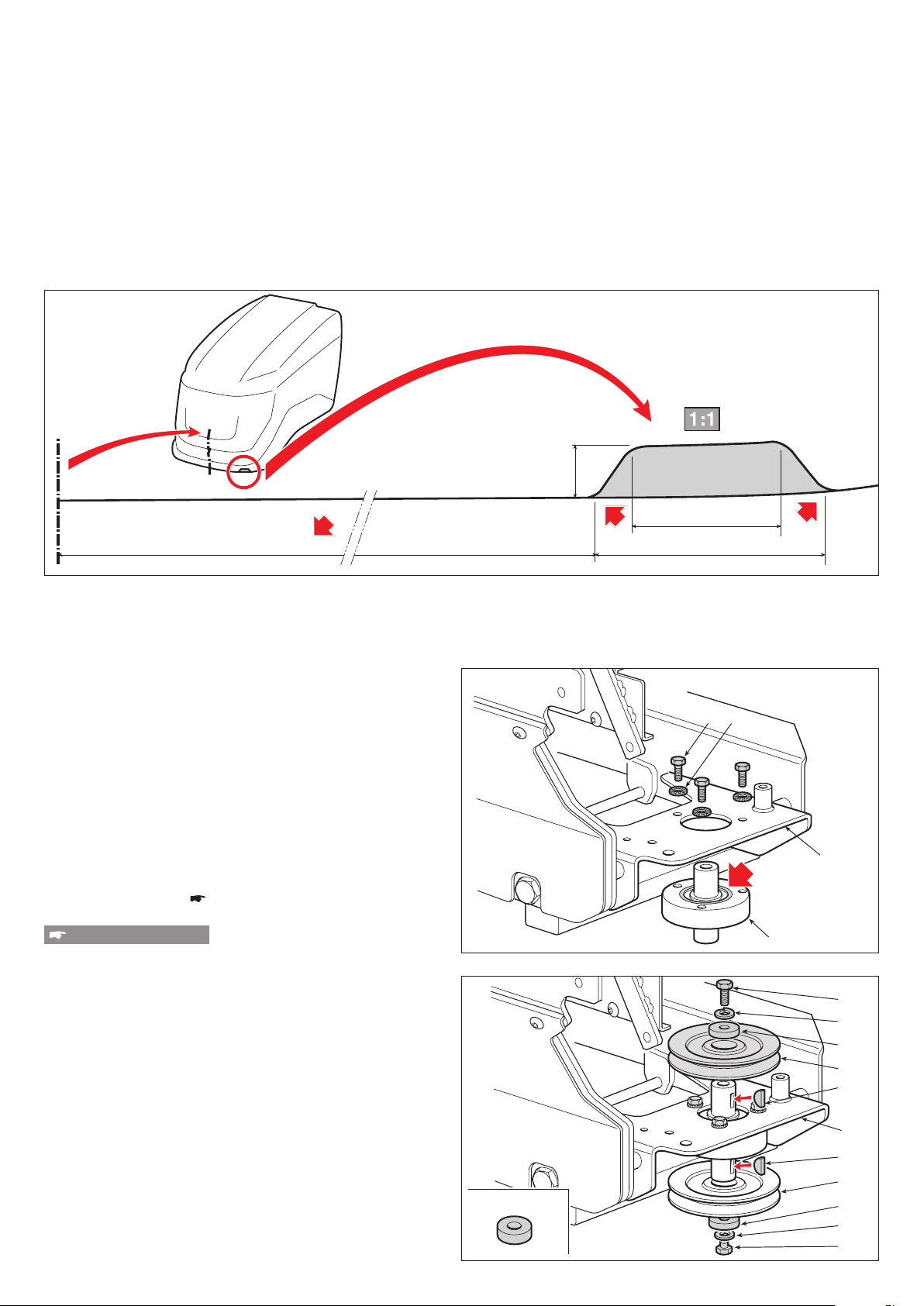

Fit the support with the return shaft (1) on the lower section

of the lifting module frame (2), making sure that the external

bearing ring is in contact with the frame (2).

Fix the support (1) using the screws (3) and toothed locking

washers (4), apply a tightening torque of 20-25 Nm.

Fit the disc tab (5) onto the end of the shaft and t the upper

pulley (6 - black) fastening it in place with the screw (7), the

washer (8) and the grower washer (8a) with a tightening

torque of 20-25 Nm.

Likewise, t the disc tab (5a) and the lower pulley (6a) x-

ing it with the screw (7a), the washer (8b) and the grower

washer (8c) with a tightening torque of 20-25 Nm.

Loading ...

Loading ...

Loading ...