Loading ...

Loading ...

Loading ...

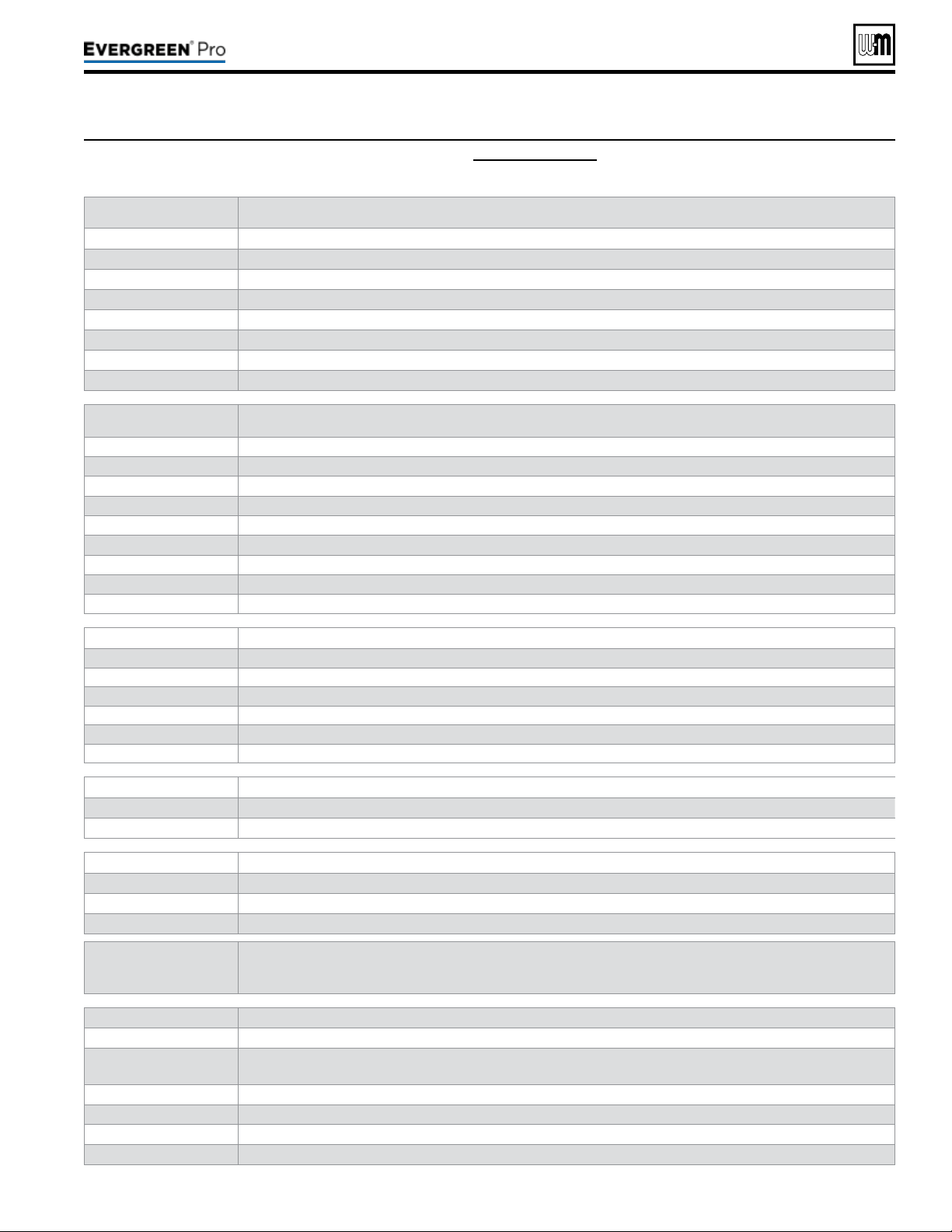

Figure83 DIAGNOSTICS menu details (continued) (see Figure 71, page 67 for access information)

Part number 550-100-211/0122

– 83 –

220 /29 9/3 00 /39 9

(continued)

Menu/Item Comment

RunTimes

Burner Time

Displays cumulative time the burner has been active (can be increased by user)

Rotate Time

Records the days of operation passed from the last time the Master boiler rotated the ring sequence.

Input 1 Time

Displays cumulative time that Input 1 has been closed (Or 0-10V ≥ 1 volt)

Input 2 Time

Displays cumulative time that Input 2 has been closed

Input 3 Time

Displays cumulative time that Input 3 has been closed

Network Time

Records time this boiler was running on a network call for heat generated by the Master boiler

Ignition Count

Displays total number of successful ignitions

Master-Shadow

Comm

Boiler ID

Displays boiler control type and ID number

Linked to Master

Shows if control is currently linked to a Master control

Boilers on Network

Shows number of boilers currently on network

Requested to Run

Shows if this control is being requested to satisfy a network call

Type

Shows whether the control is Network-P1, Network-P2, or NONE

Requested Mod Rate

Rate coming from the Master

Max Boiler Temp

Displays maximum allowable boiler temperature

Boiler On Diff

Temperature dierential from master boiler for network priorities

Boiler Off Diff

Temperature dierential from master boiler for network priorities

NetworkBoilers Formultipleboilersonly–SeeEVGAdvancedmanual

###%

Shows current rate of boiler

###F

Shows Boiler Out temperature of boiler

######

Shows priority being satised, updated based on active demand

######

Shows system type of call for heat, updated based on active demand

# OF #

Shows the sequence position of that boiler in all the boilers available

BLR#

Shows boiler number this data belongs to

NetworkInputs

Boiler number

Displays boiler number

Inputs

Displays input’s conguration and whether it is active. If input is active, it will be displayed in BOLD print

SoftwareVersions

Display Soware version of the microprocessor on the display circuit board

Main Micro Soware version of the main microprocessor on the control circuit board

Second Micro Soware version of the second microprocessor on the control circuit board

TORESETALL

HISTORYCOUNTERS

TOZERO:

To reset all history counters to zero: Enter the PAST ERRORS menu. en press and hold the le and right arrows

located below the control display. Hold for 5seconds. is will cause ALL history to be deleted. To maintain

history, reset counters individually.

PastErrors

Control Fault

Displays number of control faults

Ignition Retries

Displays cumulative ignition attempts. It is recommended that his be reset during yearly maintenance by holding

down the Le and Right arrows or by selecting this line and pressing the Enter button

Manual Reset Cnt

Displays number of manual reset lockouts since last cleared

Auto Reset Cnt

Displays number of auto reset lockouts since last cleared

Lockout History 1

Choose this to view the most recent error recorded

Fault Name

Displays the name of the fault that occurred

Loading ...

Loading ...

Loading ...