Loading ...

Loading ...

Loading ...

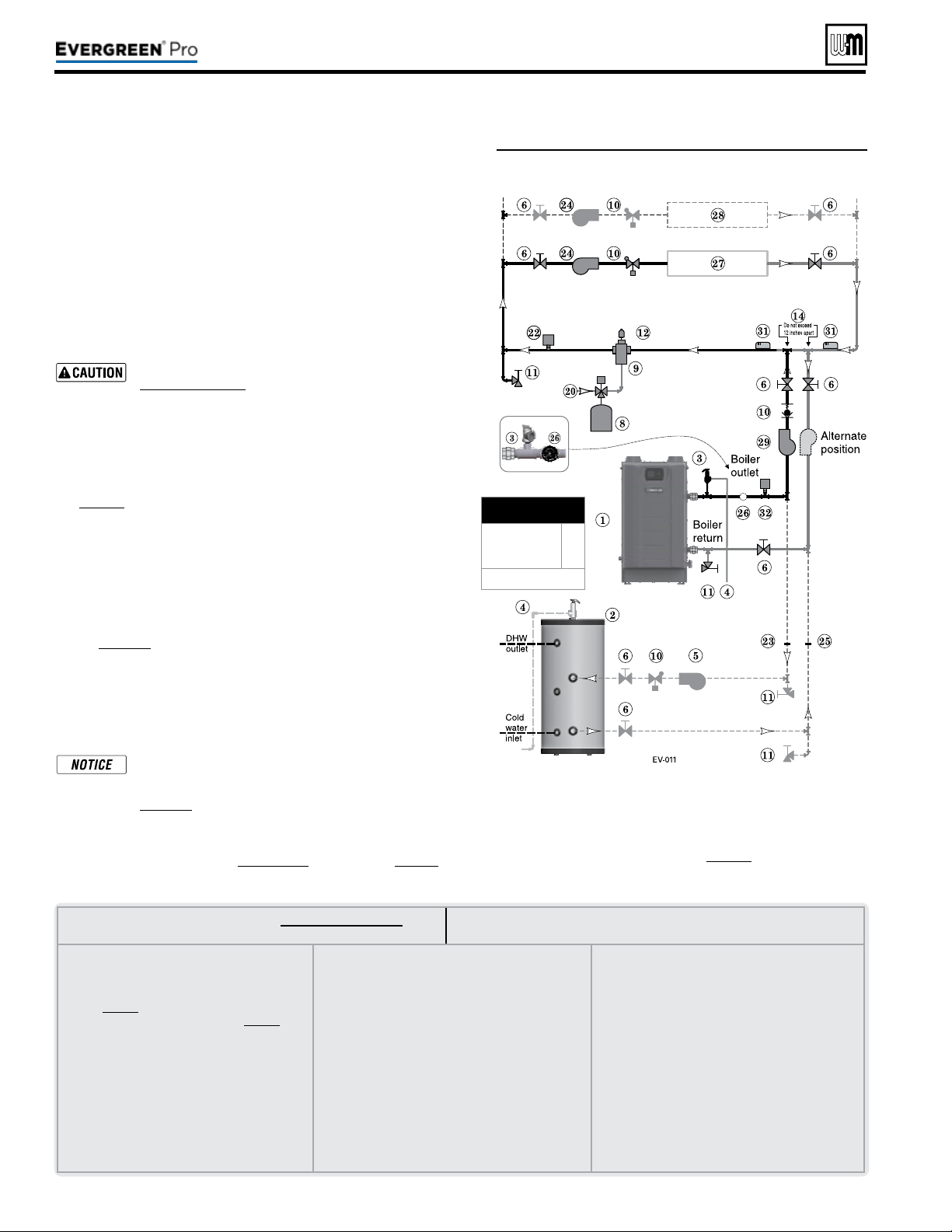

LEGENDforFigure53andFigure54,page45

Note:This is a common legend for all piping diagrams.

Not all items listed appear in every gure.

1 Evergreen boiler

2 Indirect Water Heater, if used

3 Relief valve, supplied with boiler, eld piped —

MUST be piped to boiler supply connection —

see page41 for information

4 Relief valve piping to drain — see page41.

5 DHW circulator

6 Isolation valves

7 System circulator

8 Expansion tank, diaphragm type, if used

9 Air separator

10 Flow/check valves or spring check

11 Purge/drain valves

(one drain valve shipped loose

with boiler)

12 Auto air vent

13 Zone valves

14 Primary/secondary connection (tees no more than

12 inches apart)

15 Expansion tank, closed type, if used (some chiller

systems may use a diaphragm-type expansion tank)

16 Water chiller

17 Check valve

18 Y-strainer

19 Balancing valve

20 Make-up water supply – Use applicable codes to

determine if backow preventers, pressure reducing

valves, and ll valves may be required

21 By-pass pressure regulator,

Recommended for zone

valve systems unless other provision is made

22 High limit temperature control, when required by

local code or for a radiant system.

23 DHW tank boiler water supply connection, when

used

24 Zone circulator

25 DHW tank boiler water return connection, when

used

26 Pressure/temperature gauge, supplied with boiler,

eld piped

27 Heating circuits

28 Additional heating circuits, if any

29 Boiler circulator

30 Mixing device, if any

31 System supply and return sensors: Strap system

sensors to lines as shown, at least 6 pipe diameters

(but no more than 3 feet) from boiler connection

tees.

32

Low Water Cut-o

Part number 550-100-211/0122

– 44 –

See Figure53.

1. is conguration is for circulator-zoned systems using a boiler

loop connected as a secondary circuit o of a primary system

loop. Systems zoned with circulators must pipe the boiler loop as

a secondary circuit as show.

2. Install a separate circulator (supplied by installer) for each zone

capable of delivering the proper ow and head as shown.

3. e ow/check valve shown on the boiler outlet piping prevents

gravity circulation in the boiler loop during DHW heating.

Use at least the MINIMUM pipe size shown in

Figure47,page39 on all boiler loop piping (connecting

boiler to and from the primary/secondary connection,

item14). Useonlyprimary/secondarypipingas

shown. Failure to follow these guidelines could result

in system problems.

Expansion Tank required

1. Provide a system expansion tank following the guidelines on

page42.

2. DO NOT use a closed-type tank if connecting to a water heater

that is equipped with an automatic vent.

Domestic Hot Water (DHW) tank, if used

1. DHW direct connection—Pipe from the near-boiler piping to the

DHW tank’s boiler connections as shown.

2. DHW as zone— A DHW tank can be connected as a zone if a

DHW tank is NOT already connected to the boiler. See notices

on page129 to ensure compliance with the 2007 Energy Act. See

Advanced Manual to congure Boiler Pump to run during DHW

demands and change TARGET MOD SENSOR to System Supply.

3. DHW Priority operation— Using Priority 1 for DHW (default) will

turn o lower priorities during DHW calls. e MAX ON TIME

setting can be adjusted to limit how long this occurs. Use Priority

2 or 3 for DHW if DHW priority is not desired.

Overriding the Outdoor Reset function by setting control

to DHW mode when system is intended for space heat-

ing may violate Section 303 of the 2007 Energy Act. See

page129 for compliance information and exemptions.

Controlling the circulators

1. e control can control up to four circulators (boiler circulator

and three others). Refer to Field wiring, beginning on page52, for

instructions on wiring to circulators.

Figure53 Circulator zoning plus optional DHW piping

2. e factory default settings are: all three inputs are set up

for Space Heating (

Priority 2). Each input correlates to its

respective circulator output. For DHW Priority applications,

wire aquastat to Input 1 and assign to Priority 1. See Field wir-

ing instructions, beginning on page52, for details.

3. For more than 3-zones, use Weil-McLain WMCR zone Circ

controller.

(continued)

220 /29 9/3 00 /39 9

MINIMUM

Boiler loop pipe size

Evergreen 220

Evergreen 299/300,

399

1¼”

1½”

See CAUTION at left.

Loading ...

Loading ...

Loading ...