Loading ...

Loading ...

Loading ...

e boiler contains ceramic ber materials. Use

care when handling these materials per instructions

on page94 of this manual. Failure to comply could

result in severe personal injury.

1. Allen wrench, 3mm (T-wrench preferred).

2. 8mm socket with 8-inch extension.

3. Metric wrench or socket, 10mm.

4. T20 Torx.

5. 5/16” socket or nut driver.

6. Torque wrench.

7. Putty knife.

1. Shut down the boiler:

a. Follow “To Turn O Gas to Appliance” instructions on

boiler and Operating instructions.

b. Close the boiler manual gas valve.

2. Allow time for the boiler to cool to room temperature if it

has been ring.

3. Remove jacket front door by removing the two (2) latches at

the top of the jacket door.

4. Rotate and li the jacket door away from the boiler to remove.

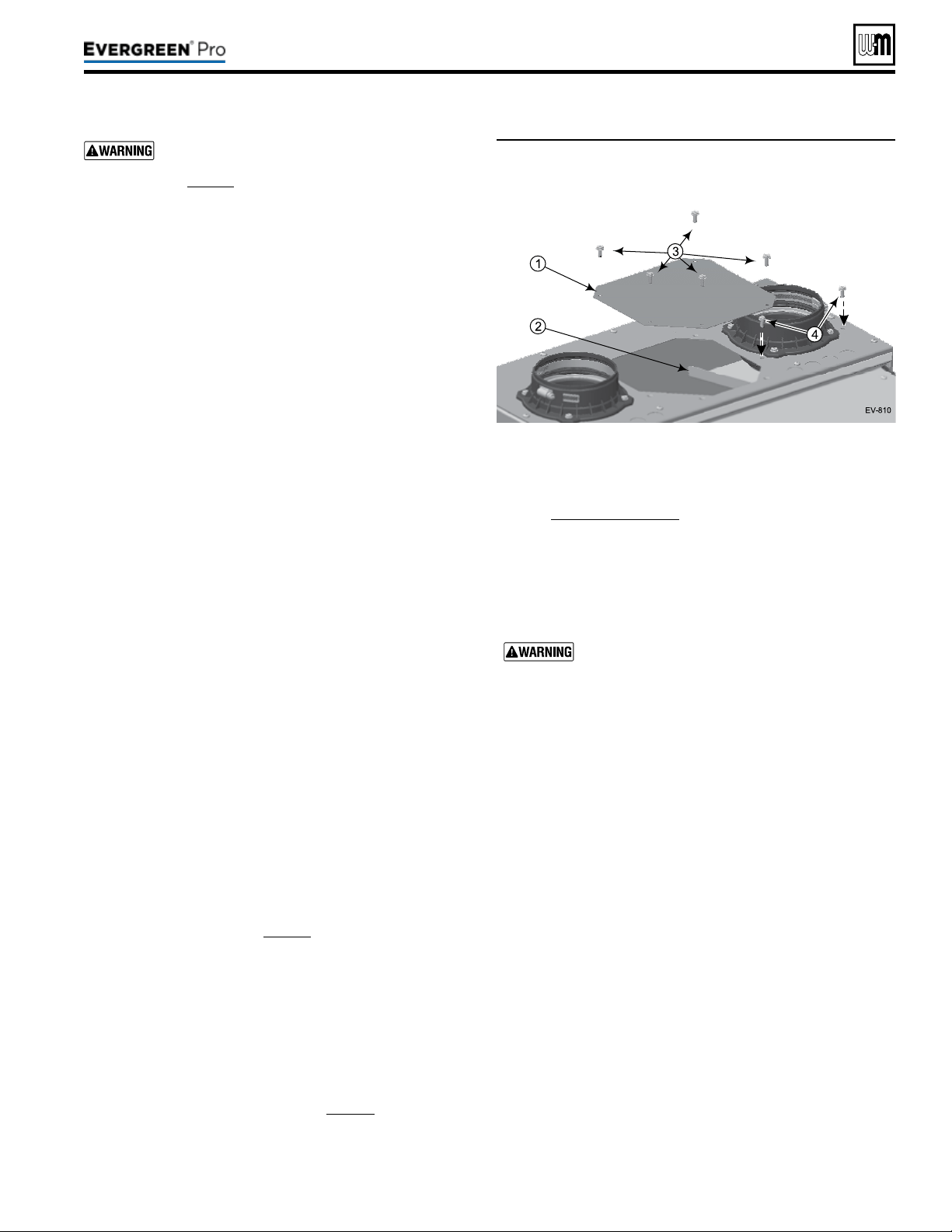

5. See Figure106 (EVG220 shown).

a. Remove the burner access panel (item1) located on the

top of the boiler jacket by removing the screws (item3).

b. Remove the air bae (item2) and screws (item4) from

the jacket top as shown.

1. Carefully remove the ignition electrode assembly, following

the instructions in “Remove and inspect ignition electrode

assembly and wiring” on page97.

2. Set ignition electrode assembly and new gasket aside for

later re-insertion.

1. Carefully remove the ame sense rod assembly, following the

instructions in See instructions on page97 under “ Inspect

Flame Sense Rod”.

2. Set the ame sense rod with new gasket aside for later re-

insertion.

1. See Figure109,page115 (EVG220 shown).

2. Use a T20 Torx to remove the four (4) M4 screws (item10)

that secure the burner access cover (item4) to the heat ex-

changer cover plate (item6).

3. Remove the burner access cover (item4) and the burner

(item11).

Use caution when removing the burner to pull it

directly up and out. DO NOT angle the burner as

you remove it. Angling the burner could cause it to

strike the refractory, damaging the refractory and

causing fragments to fall into the heat exchanger.

Should this happen, a heat exchanger refractory

replacement kit must be installed and the heat ex-

changer must be thoroughly cleaned following the

procedures given in this manual and the refractory

replacement instructions.

4. Remove and discard the burner gasket (item12). is gasket

is graphite and may pull apartor stick to the burner on re-

moval. Use a so brush if necessary to remove residue. DO

NOT allow debris to drop into the heat exchanger. A new

gasket must be installed later when the burner is re-inserted.

5. Inspect the burner access cover seal (item13). Discard and

use a new seal during re-assembly if the seal is damaged in

any way.

6. Inspect the interior of the burner. Brush and vacuum the

interior if needed to remove lint or sediment. Alternative

cleaning methods:

a. Blow air or nitrogen from the inside out.

b. Clean with a water spray from inside the burner.

7. Inspect the burner exterior. It must be in good condition,

with no visible damage.

8. Clean the under side of the burner ange (see item15) with

a so brush to remove any gasket fragments remaining.

9. Set the burner aside for re-insertion later.

Figure106 Remove the burner access panel and screws

(1 and 3) and air bafe and screws (2 and 4)

from the jacket top as shown

Part number 550-100-211/0122

– 111 –

220 /29 9/3 00 /39 9

Loading ...

Loading ...

Loading ...