Loading ...

Loading ...

Loading ...

Part number 550-100-211/0122

– 16 –

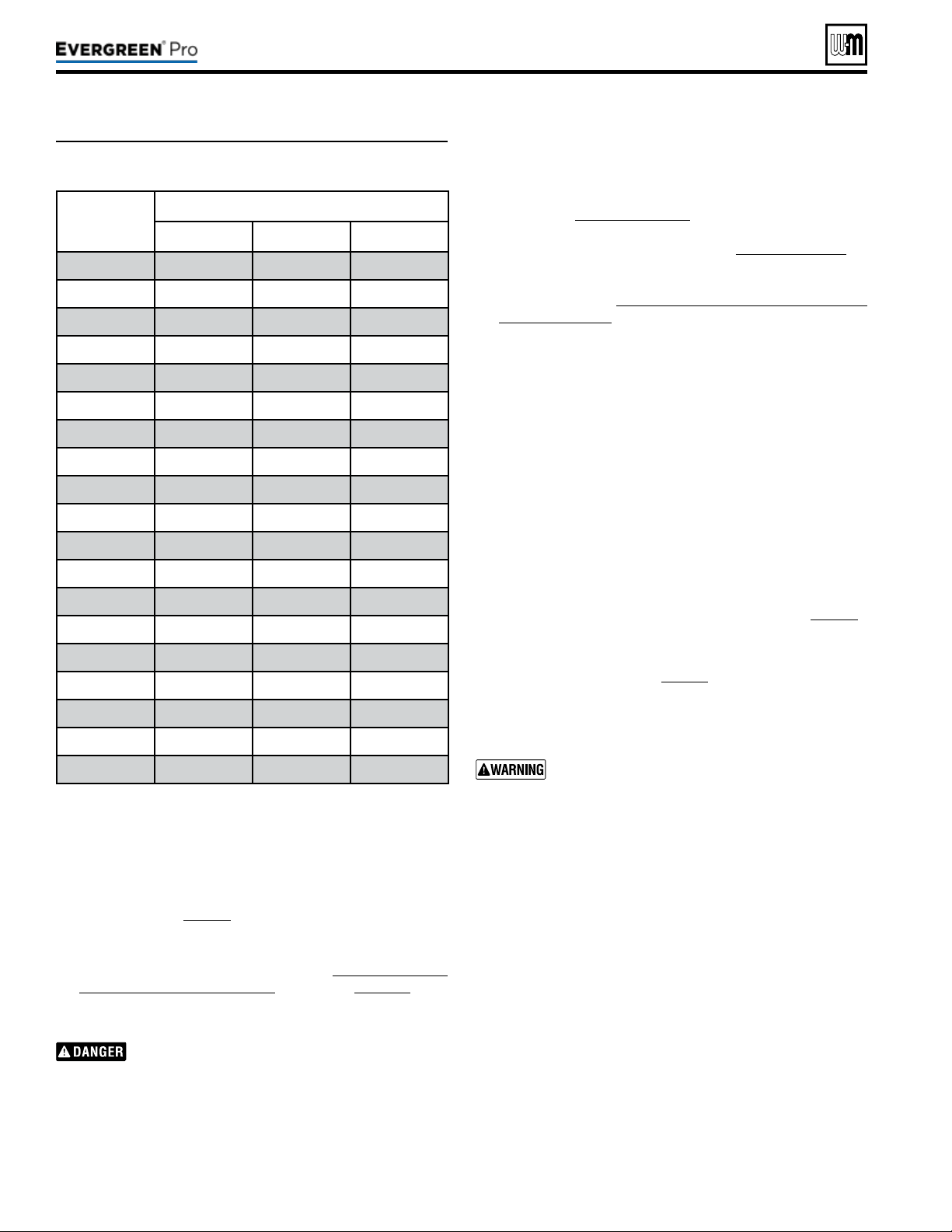

Table2: Low-re blower speeds—Minimum blower speed

settings according to altitude settings.

(continued)

220 /29 9/3 00 /39 9

is set between 96% and 100%. Also verify that the ‘Min

Rate” is set to 10% or the minimum rate allowed (if above

2000 . elevation). Adjust control settings if not at proper

rate. Verify that boiler is operating at the expected ring

rate at both high- and low-re during combustion analysis.

Refer to Table 2, page16 for proper low-re rate based on

altitude settings.

19. Prior to turning on the boiler, review the procedure and

control sequence for the operation of the Manual Test Mode

for Single and Multiple Boilers starting on page101. e

procedure diers between boilers set as a single or multiple-

boiler unit.

e use of a ue gas analyzer is required to convert

this unit and determine proper gas valve settings.

Do not perform this conversion without a ue gas

analyzer. Improper gas valve settings can cause

severe personal injury, death, or property damage.

20. Do NOT allow the boiler to modulate freely until the com-

bustion analysis and adjustment is complete. Turn on and

Altitude

Setting

(ft.)

LowestRateforAltitude

220 299/300 399

0-2000 10% 10% 10%

2500 11% 11% 12%

3000 11% 11% 12%

3500 12% 11% 12%

4000 12% 12% 13%

4500 13% 12% 13%

5000 13% 12% 13%

5500 13% 13% 14%

6000 14% 13% 14%

6500 14% 13% 14%

7000 15% 14% 15%

7500 15% 14% 15%

8000 15% 14% 16%

8500 16% 14% 16%

9000 16% 15% 16%

9500 17% 15% 17%

10000 17% 15% 17%

10500 17% 16% 17%

11000 18% 16% 18%

connect properly working, calibrated combustion analyzer to

the boiler ue pipe. Fire the boiler and force it to High Fire in

Manual Test Mode. Adjust the high re combustion rst, us-

ing the throttle adjustment screw, to the CO2 and CO ranges

specied in Figure89,page91, by model size. en, force

the boiler to Low Fire and adjust the oset regulating screw

to the CO2 and CO ranges specied in Figure89,page91, by

model size. Reinstall the slotted cap over the oset adjustment

screw. Follow the full startup instructions found in this Boiler

Manual including Re-check the Maximum and Minimum

CO2 and CO rate.

21. e coarse adjustment prescribed by this manual should

result in combustion settings that allow for ignition and

are a starting point for further adjustment. If, aer making

the coarse adjustments prescribed above, the boiler will not

light, turn the throttle screw only counterclockwise (Q) an

additional 1/4 turn and attempt to light again. Repeat for a

total of up to one full turn. If, aer following the procedure

above, the boiler still will not ignite or, during combustion

analysis, the analyzer reads less than 1.0% O2, contact Weil-

McLain Technical Services for assistance.

22. Check for gas leaks and conrming proper performance.

Perform complete start-up sequence (beginning on page86),

including check for gas leaks and checking for proper operation.

Aer placing the boiler in operation, the ignition system safety

shuto device must be tested, page91.

Install front door aer servicing. e front door

must be securely fastened to the boiler frame

to prevent boiler from drawing air from inside

the boiler room. is is particularly important if

the boiler is located in the same room as other

appliances. Failure to keep the door securely fastened

could result in severe personal injury or death.

1. Aer installation is complete and boiler is set up for propane

gas, ll out and attach the propane conversion label next to

the boiler rating label (le side of cabinet).

2. Contractor/installer is responsible for completing the in-

formation required on label (provided in kit) and attaching

installer conversion label next to the boiler rating label.

Loading ...

Loading ...

Loading ...