Loading ...

Loading ...

Loading ...

31

PRODUCT CARE

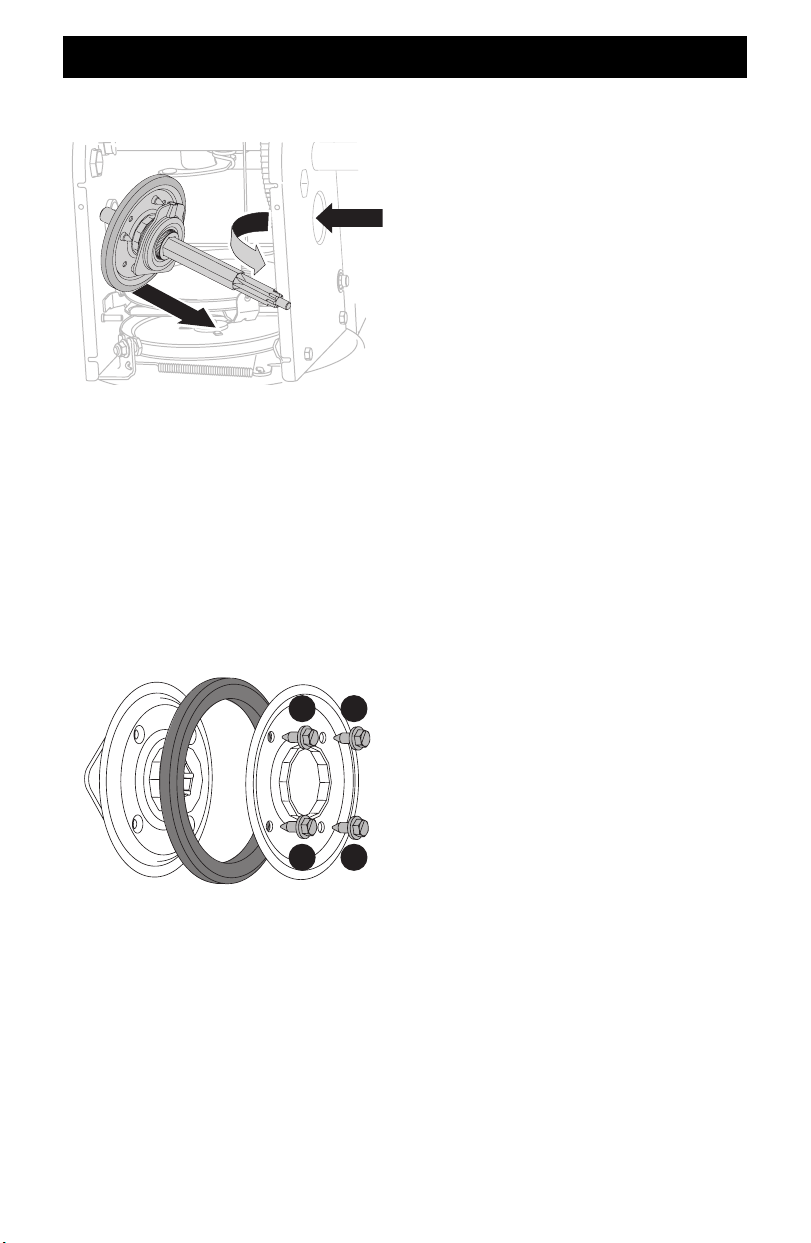

6. Carefully position hex shaft downward and to left before

carefully sliding friction wheel assembly off shaft (Figure 92).

Figure 92

NOTE: If you’re replacing friction wheel assembly as a whole,

discard the worn part and slide new part onto hex shaft.

7. Follow previous steps in reverse order to reassemble

components.

8. Perform Drive Control test shown on page 18.

If you’re disassembling friction wheel and replacing only rubber

ring, proceed as follows:

NOTE: Not all friction wheels are serviceable. If this is the case,

simply replace friction wheel assembly.

9. Remove four screws (b) which secure friction wheel’s side

plates together (Figure 93).

b

b

b

b

Figure 93

10. Remove rubber ring from between the plates.

11. Reassemble side plates with a new rubber ring.

NOTE: When reassembling friction wheel assembly, make

sure that rubber ring is centered and seated properly

between the side plates. Tighten each screw only one

rotation before turning wheel clockwise and proceeding with

next screw. Repeat this process several times to ensure plates

are secured with equal force (between 115-145 in-lbs).

12. Apply a light coating of Bostik Regular Grade Never-Seez® to

hex shaft.

13. Slide friction wheel assembly back onto hex shaft and follow

the steps above in reverse order to reassemble components.

14. After replacing friction wheel, perform Drive Control test

shown on page 18.

NOTE: Make sure shift lever pin is in place in bearing housing

(Figure 91 inset).

Hydro Transmission (If Equipped)

NOTE: See your authorized service dealer to have the Hydro

Transmission serviced or contact Customer Support for assistance

and the name of your nearest servicing dealer.

BATTERY DISPOSAL

IMPORTANT: Refer to instructional manual supplied with battery

charger for disposal instructions.

Loading ...

Loading ...

Loading ...