Loading ...

Loading ...

Loading ...

18

SET-UP

a

e

c

b

d

f

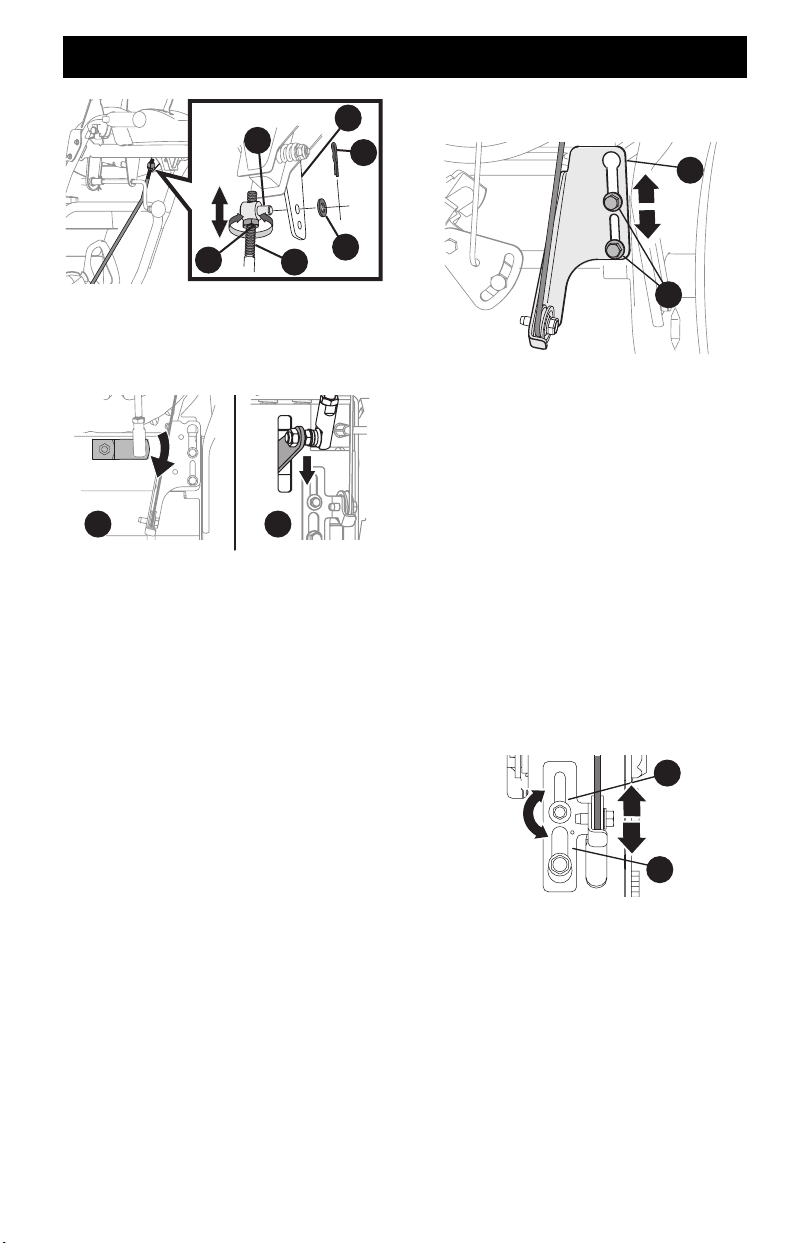

Figure 56

3. Make sure the shift lever on the back of the transmission is

rotated downward to the full extent of its rotation. See Figure

57, Detail “A” for models without hydro transmission or Detail

“B” for models with hydro transmission.

A B

NON-HYDRO MODELS HYDRO MODELS

Figure 57

4. If necessary, loosen the jam nut (f) and rotate the ferrule

up or down on the shift rod until the ferrule aligns with the

upper hole in the shift lever (Figure 56). Tighten jam nut.

5. Insert the ferrule into the upper hole and secure with the

washer and cotter pin.

Drive Control (NON-Hydro Models) (If Equipped)

When drive control lever is released and in disengaged “UP”

position, cable should have very little slack. It should NOT be

tight.

NOTE: If excessive slack is present in drive cable or if drive is

disengaging intermittently during operation, the cable may be in

need of adjustment.

Check adjustment of drive control lever as follows:

1. With drive control lever released, push snow blower gently

forward. It should roll freely.

2. Engage drive control lever and gently attempt to push the

snow blower forward. The wheels should not rotate or roll

freely.

3. If equipped with a shift lever, with drive control lever

released, move shift lever back and forth between the R2

position and the F6 position several times. There should be no

resistance in the shift lever.

NOTE: If any of the above tests fail, the drive cable is in need of

adjustment. Proceed as follows:

4. Shut OFF engine, remove safety key or disconnect spark plug

wire. Refer to the Engine Operator’s Manual.

5. Loosen the two hex screws (a) on drive cable bracket (b)

(Figure 58).

a

b

Figure 58

6. Position drive cable bracket upward to provide more slack (or

downward to increase cable tension).

7. Re-tighten the hex screws.

8. Check adjustment of drive control lever as described above to

verify proper adjustment has been achieved.

Drive Control (Hydro Models) (If Equipped)

When drive control lever is released and in disengaged “UP”

position, cable should have very little slack. It should NOT be

tight.

NOTE: If excessive slack is present in drive cable or if drive is

disengaging intermittently during operation, the cable may be in

need of adjustment.

1. Shut OFF engine, remove safety key or disconnect spark plug

wire. Refer to the Engine Operator’s Manual.

2. Loosen upper hex screw (a) on drive cable bracket (b)

(Figure 59).

a

b

Figure 59

3. Position bracket upward to provide more slack (or downward

to increase cable tension).

4. Re-tighten upper hex screw.

5. Check for excessive slack in drive control cable. If necessary

repeat Steps 2-4 to re-adjust the drive control.

Loading ...

Loading ...

Loading ...