Loading ...

Loading ...

Loading ...

98 Servicing Your Honda

Suspension

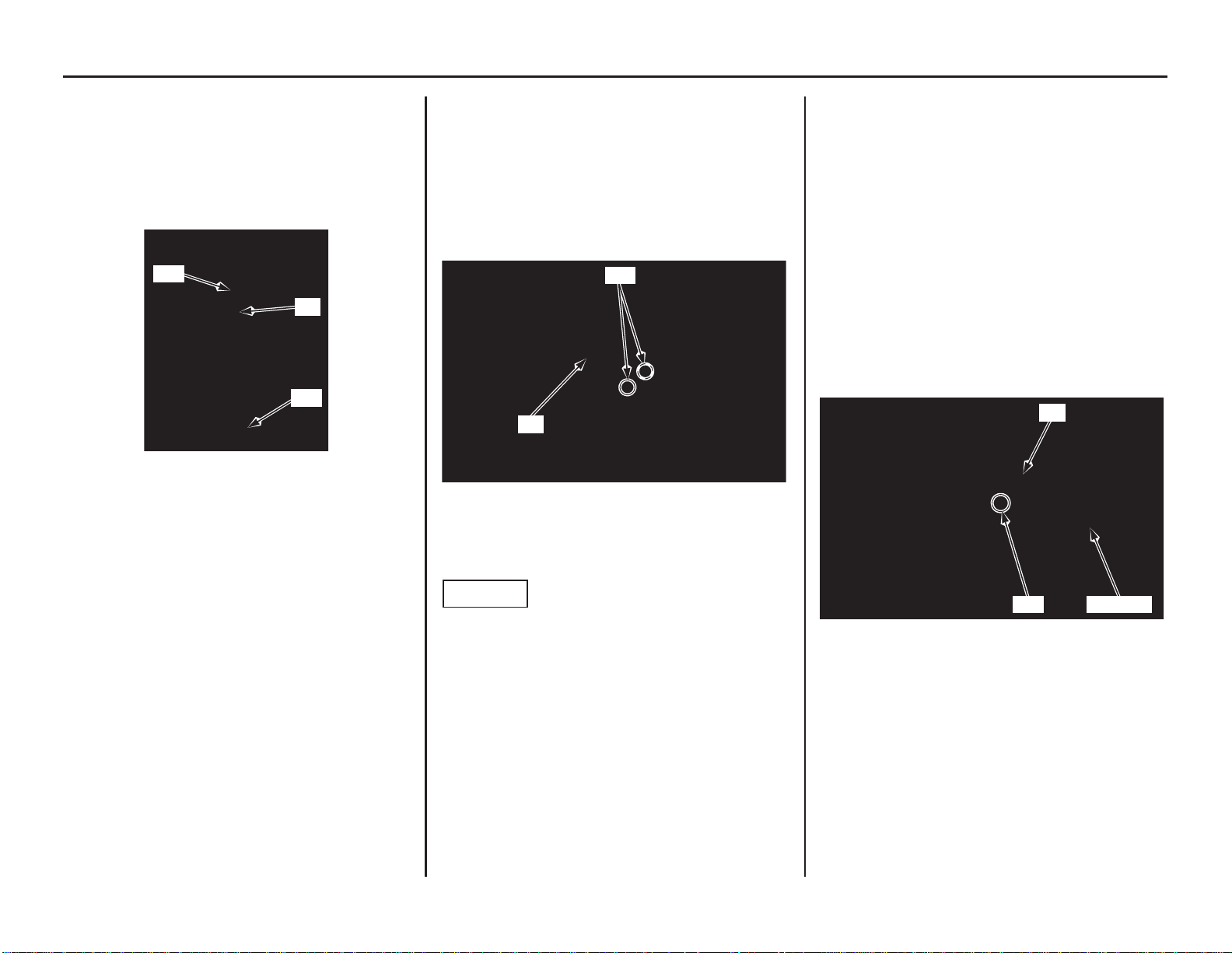

15. Cover the fork damper piston rod end with

shop towel (11) to prevent fork damage.

Cover the oil holes with shop towel to prevent

blow out of fork oil.

Blow the extra oil off from the fork damper

assembly (4) by pumping the fork damper

piston rod to full stroke.

16. Drain the extra oil from the oil holes (12) of the

fork damper assembly (4).

By doing above procedure, about 0.2 US oz (5

cm

3

) of fork oil will be drained from the fork

damper through the oil hole and cause 8.2 US oz

(243 cm

3

) of fork oil to be left in the fork damper

assembly.

Pour the drained oil into a suitable container and

dispose of it in an approved manner (page 148).

NOTICE

Improper disposal of drained fluids is harmful to

the environment.

17. Blow out any oil from the oil hole (12) of the

fork damper assembly (4) using compressed

air.

Wipe off the oil completely from the fork

damper.

If your cannot use compressed air, remove the

fork air pressure release screws (13) from the

fork bolt assembly.

Hold the fork damper upside down for 20

minutes and drain the fork oil.

18. Apply recommended fork oil to a new O-ring

(14), and then install a new O-rings on the air

pressure release screws (13).

Tighten the air pressure release screws to the

specified torque:

1.0 lbf·ft (1.3 N·m, 0.1 kgf·m)

(4) fork damper assembly (11) shop towel

(11)

(11)

(4)

(4) fork damper assembly (12) oil holes

(4)

(12)

(4) fork damper assembly

(12) oil hole

(13) air pressure release screws

(14) O-rings (new)

(4)

(12) (13) (14)

Loading ...

Loading ...

Loading ...